I. Instrumentation Engineer

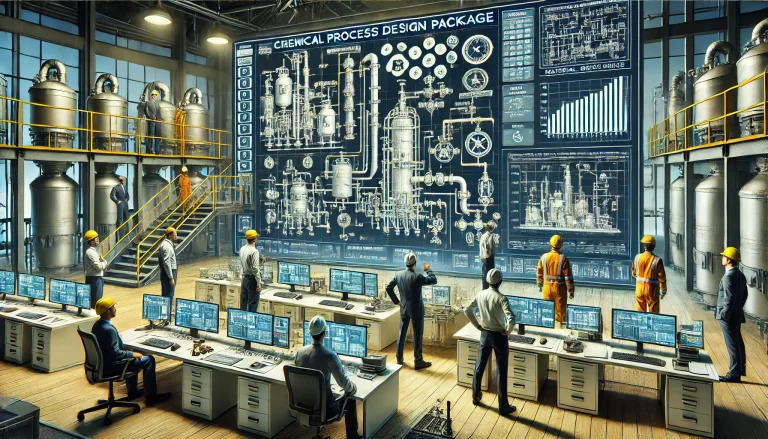

1. Design and Planning

- Participate in developing instrumentation system design plans based on project requirements. Factor in process needs, safety standards, and cost control.

- Select appropriate instruments by evaluating reliability, precision, and compatibility with the intended application. For instance, in a petrochemical plant, selecting flame-proof instruments for hazardous areas ensures safety compliance.

- Prepare detailed technical drawings, including schematic diagrams, wiring diagrams, and installation layouts. Ensure all designs adhere to industry standards such as ISA or IEC.

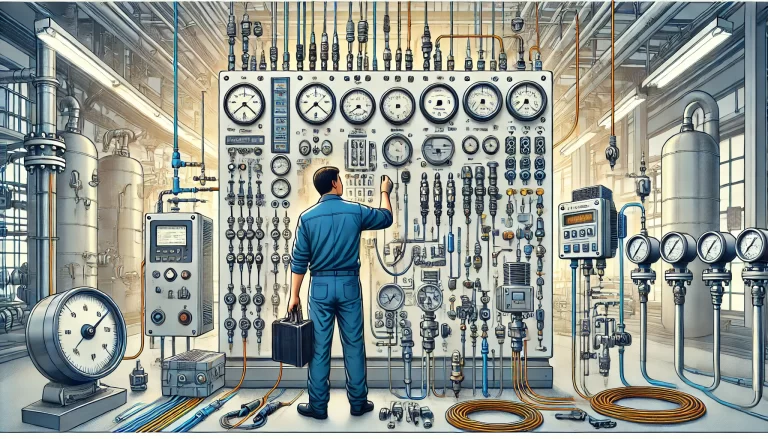

2. Installation and Commissioning

- Supervise the installation of instrumentation systems to guarantee compliance with design specifications and installation protocols. For example, ensure the proper alignment of flow meters and secure mounting of pressure transmitters.

- Conduct system commissioning, including calibration and parameter configuration of instruments. Address issues like signal interference or incorrect readings during calibration to ensure system accuracy and reliability.

- Collaborate with electrical and mechanical engineers to ensure seamless integration of instrumentation systems with other engineering systems.

3. Maintenance and Troubleshooting

- Develop preventive maintenance schedules to minimize downtime. For example, schedule quarterly calibrations of temperature sensors to maintain process consistency.

- Analyze and resolve equipment failures, such as diagnosing sensor drift in thermocouples or wiring faults in PLC systems. Provide quick solutions to avoid production delays.

- Maintain detailed records of instrument performance, including maintenance logs and fault analyses, to support decision-making for equipment upgrades.

4. Technical Support and Training

- Provide on-site support for operations staff, addressing issues like incorrect readings or alarm malfunctions. Ensure proper operation of systems through hands-on guidance.

- Organize training sessions for new employees on the principles and operation of specific instruments, such as DCS (Distributed Control Systems) and SCADA (Supervisory Control and Data Acquisition).

- Stay informed about the latest advancements in instrumentation technology and propose upgrades, like transitioning to wireless sensors for enhanced data accessibility.

5. Project Management and Coordination

- Oversee project timelines, ensuring milestones like design completion, installation, and commissioning are met on schedule.

- Communicate effectively with contractors, suppliers, and internal departments to resolve challenges during project implementation, such as delays in equipment delivery.

- Develop and refine procedures and workflows for instrumentation management, enhancing operational efficiency.

II. Instrumentation Administrator

1. Instrument Management

- Maintain a comprehensive equipment inventory, detailing specifications, installation dates, calibration intervals, and maintenance history.

- Design and implement maintenance plans, ensuring timely cleaning, calibration, and inspection of devices like pressure transmitters and flow controllers.

- Monitor repair progress for malfunctioning instruments, ensuring quality standards are met and lessons learned are documented to prevent recurrence.

2. Technical Oversight

- Gain proficiency in the operating principles and parameters of a wide range of instruments. Provide practical demonstrations to operators, such as the correct procedure for recalibrating gas detectors.

- Research and recommend new technologies, such as adopting smart sensors for enhanced data accuracy and ease of integration into existing systems.

3. Quality Assurance

- Schedule periodic calibrations to meet industry and regulatory standards. For instance, ensure weighing scales in food processing plants are compliant with legal-for-trade certifications.

- Audit newly installed instruments for quality and performance compliance before commissioning.

4. Safety Compliance

- Implement safety checks for instrumentation in hazardous environments, ensuring flameproof or intrinsically safe equipment adheres to ATEX or other relevant standards.

- Train team members on emergency procedures and the use of protective devices to mitigate risks in high-voltage or high-temperature environments.

5. Documentation and Reporting

- Compile and update technical documentation, such as operation manuals, calibration certificates, and troubleshooting guides.

- Prepare periodic reports on equipment performance and maintenance trends for managerial review, including recommendations for future investments.

III. Instrumentation Supervisor

1. Team Leadership

- Allocate tasks based on team members’ expertise, ensuring efficient execution of routine checks and emergency repairs.

- Conduct regular performance evaluations and provide feedback to foster skill development among team members.

2. Technical Problem-Solving

- Analyze and resolve complex issues, such as diagnosing irregular signal outputs from control valves or identifying faulty connections in telemetry systems.

- Lead troubleshooting efforts during unexpected breakdowns, ensuring rapid recovery of critical systems.

3. Safety Enforcement

- Develop and enforce safety protocols, such as ensuring proper lockout/tagout procedures during instrument maintenance.

- Organize regular safety drills and workshops to enhance the team’s emergency response capabilities.

4. Equipment Oversight

- Monitor equipment life cycles and recommend replacements before failures occur. For instance, track corrosion levels in sensors used in corrosive environments.

- Coordinate with suppliers to procure spare parts or replacement equipment, ensuring minimal disruption to operations.

5. Interdepartmental Collaboration

- Maintain open communication with production, quality, and maintenance teams to align instrumentation activities with overall operational goals.

- Work closely with project managers and engineers during upgrades or expansions, providing insights into instrumentation needs and potential integration challenges.

Results-Oriented Approach

To measure the success of these responsibilities:

- Use KPIs such as system uptime, calibration compliance rates, and incident response times.

- Conduct regular audits to identify and address inefficiencies.

- Foster continuous improvement through feedback loops, including post-maintenance reviews and project debriefings.