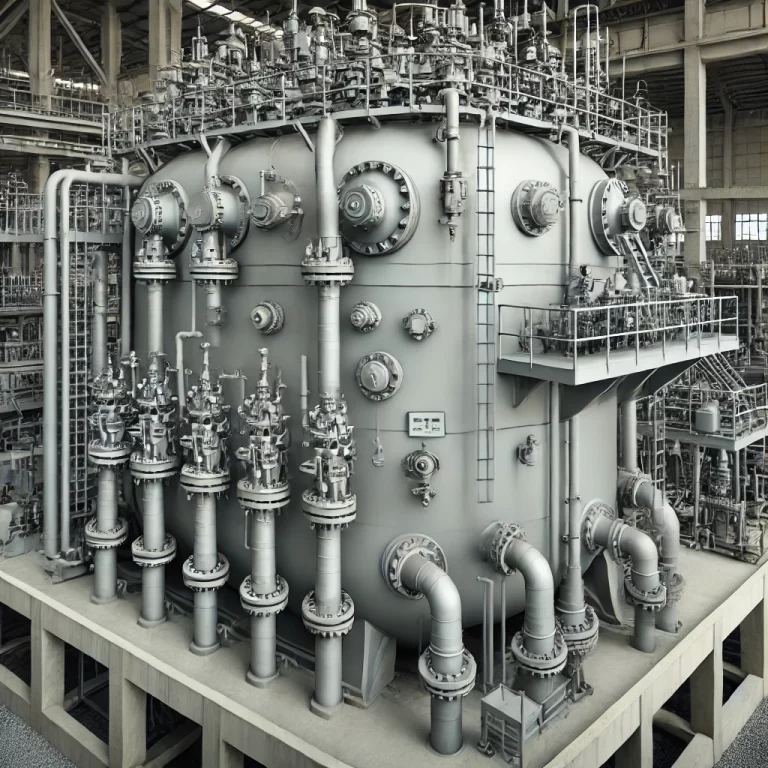

Spherical storage tanks, commonly used for storing pressurized gases or liquids, are equipped with safety valves to ensure safe operation by preventing overpressure scenarios. Configuring and using two safety valves appropriately is critical to maintaining system integrity and avoiding potential hazards. This article provides a detailed explanation of how to configure and use dual safety valves effectively.

1. Configuration Principles

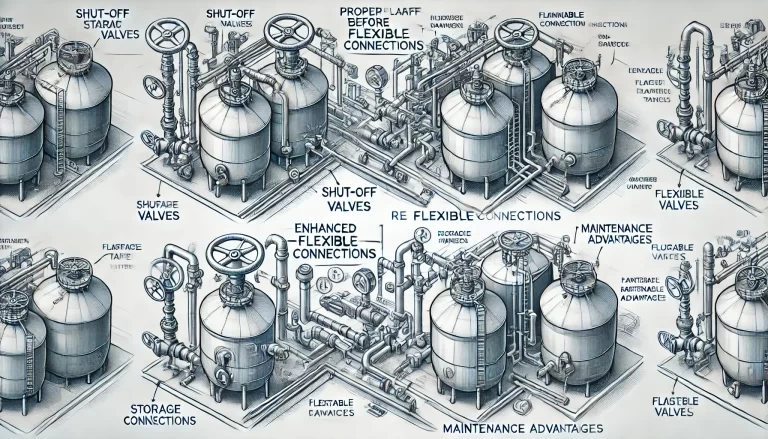

Parallel Configuration

The two safety valves are installed in parallel, with each valve having its independent inlet and outlet. This setup allows either valve to operate without interference from the other. Parallel installation ensures redundancy: if one valve fails or is under maintenance, the other can continue to provide overpressure protection.

Pressure Setpoints

- Primary Safety Valve: The primary valve is configured to open at a pressure slightly below the tank’s design pressure, typically at or just below the Maximum Allowable Working Pressure (MAWP).

- Secondary Safety Valve: The secondary valve is set to open at a pressure higher than the primary valve, usually 5%-10% above the primary valve’s set pressure. This ensures the secondary valve only activates under extreme conditions when the primary valve cannot handle the pressure relief adequately.

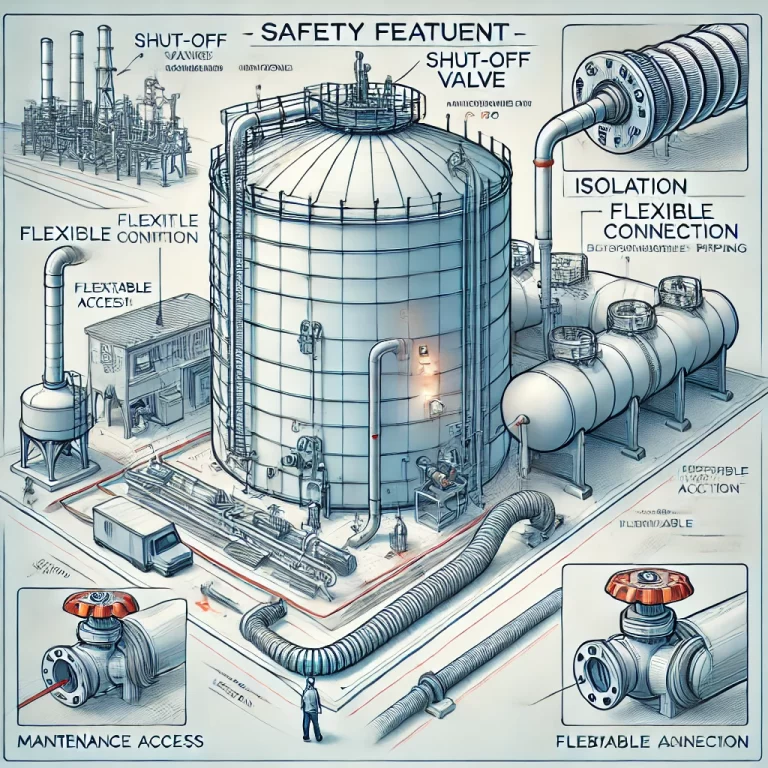

Location

The valves are installed at the highest pressure point in the tank, usually the top. This position ensures efficient pressure relief. Proper insulation or heating may be required in environments where the medium could freeze or form obstructions.

2. Operational Strategies

Normal Operation

- The primary valve handles routine overpressure events and is designed for frequent use.

- The secondary valve remains in standby mode and is only activated in emergency scenarios where the primary valve cannot manage the pressure increase.

Manual or Automated Switching

- A switching mechanism, such as a three-way valve, is often installed to facilitate the selection of either valve. This is especially useful during maintenance or testing.

- Switching should be performed gradually, with close monitoring of the tank pressure to avoid abrupt pressure changes that could destabilize the system.

Pressure Monitoring

Real-time pressure monitoring devices and alarms are critical. These systems provide early warnings of pressure anomalies and ensure that safety valves are activated promptly.

3. Inspection and Maintenance

Regular Inspection

- Inspect safety valves periodically to ensure their functionality and reliability.

- Check for corrosion, blockages, and leaks in both the valves and their connecting pipes.

Calibration and Testing

- Calibrate the safety valves to ensure the set pressure matches the design requirements.

- Perform regular blowdown tests or simulated overpressure tests to verify the valves’ response. This involves gradually increasing pressure until the valve opens to confirm its activation point.

Scheduled Maintenance

- Adhere to a maintenance schedule as recommended by manufacturers or safety regulations, typically once a year.

- During maintenance, one valve can remain operational while the other is taken offline for servicing.

4. Emergency Measures

In the unlikely event that both safety valves fail, additional emergency systems should be in place:

- Manual Relief Valves: Operators can manually relieve pressure using auxiliary valves if automated systems fail.

- Burst Discs: These one-time-use devices are designed to rupture at a specific pressure, providing a failsafe against catastrophic overpressure.

- Pressure Alarms and Shutdown Systems: Install pressure gauges with alarm systems and automatic shutdown mechanisms to mitigate overpressure risks.

5. Compliance with Standards

The configuration and operation of safety valves must comply with relevant safety standards and regulations, such as:

- ASME Boiler and Pressure Vessel Code

- API Standard 520 (Sizing, Selection, and Installation of Pressure-Relieving Devices)

- ISO Standards for Pressure Equipment These standards provide guidelines on valve sizing, material selection, and performance testing, ensuring safety and reliability.

6. Benefits of Proper Configuration and Usage

By correctly configuring and using dual safety valves, the following benefits can be achieved:

- Enhanced Safety: Overpressure risks are mitigated, protecting both personnel and equipment.

- Operational Continuity: The redundant system ensures uninterrupted operation even during maintenance or failure of one valve.

- Regulatory Compliance: Adherence to safety standards reduces liability and ensures legal compliance.

- Cost Efficiency: Preventing accidents minimizes downtime and repair costs.

Conclusion

Dual safety valves in spherical storage tanks provide critical overpressure protection, ensuring safe and efficient operation. Proper configuration, routine maintenance, and adherence to safety standards are essential for maximizing the effectiveness of these systems. By following best practices, operators can safeguard against overpressure events and ensure the long-term reliability of their storage tanks.