What Are In-Phase Oscillations?

In control systems, an in-phase oscillation occurs when a control loop in automatic mode exhibits regular oscillations. Depending on the nature of these oscillations, they can be categorized into three types:

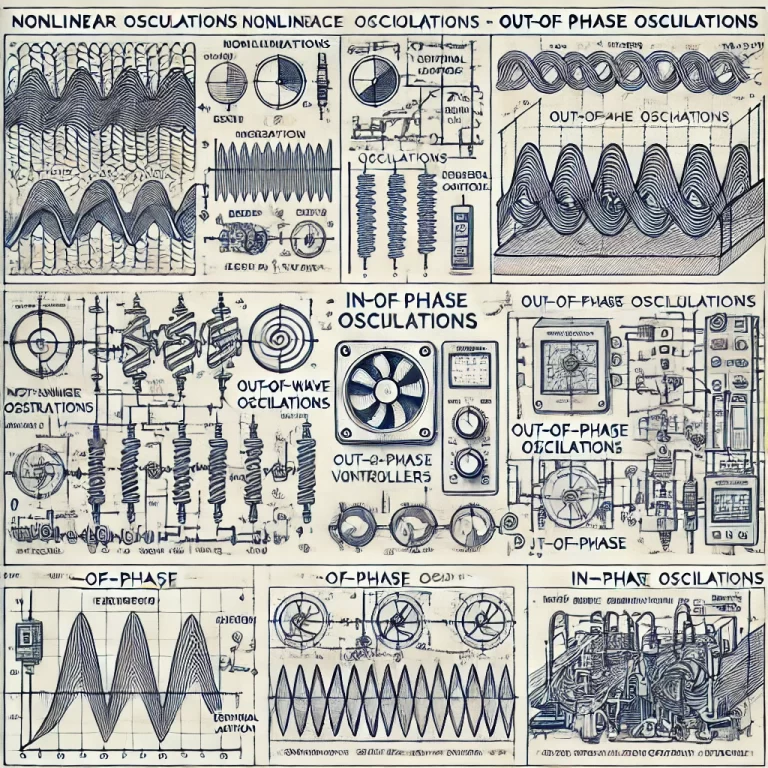

Nonlinear Oscillations:

- Symptoms: Process variable exhibits square-wave behavior, while the controller output forms a sawtooth pattern.

- Cause: This is often due to nonlinearities in the controller output.

- Solution: The preferred approach is to eliminate the nonlinearity by:

- Adjusting the working point.

- Calibrating the actuator or positioner.

- Performing maintenance or replacing defective components.

Out-of-Phase Oscillations:

- Symptoms: When the controller output reaches its peak, the process variable is near the setpoint.

- Cause: This typically indicates that integral action is too strong.

- Solution: Reduce the integral action until the oscillations disappear. If necessary, continue to weaken the integral action until stability is achieved. This type of oscillation is common in liquid level control systems.

In-Phase Oscillations:

- Symptoms: When the controller output is at its peak, the process variable also reaches a peak but deviates significantly from the setpoint.

- Solution: Depending on the root cause, there are three main principles for addressing in-phase oscillations:

- Eliminate the source of the oscillation.

- Reduce proportional action.

- Increase proportional action.

Principles for Handling In-Phase Oscillations

Case 1: Oscillations Disappear in Manual Mode

When switching the control loop to manual mode eliminates the oscillations, it indicates that the oscillations are likely caused by excessive proportional action or coupled loops. The recommended steps are:

Reduce Proportional Gain:

- Decrease the proportional gain by a factor of three. This adjustment usually stabilizes the loop.

- For coupled loops, reduce the proportional gain in any one of the coupled loops by the same factor.

Enhance Integral Action (Optional):

- If the control performance is unsatisfactory after reducing proportional gain, consider strengthening the integral action.

Consider Advanced Control Strategies:

- If issues persist, explore options such as feedforward or cascade control schemes.

- If these do not resolve the problem, reevaluate the process design and equipment or adjust operational expectations.

Case 2: Oscillations Worsen in Manual Mode

When switching to manual mode does not change the oscillation period but increases the amplitude, the issue likely stems from external disturbances. The steps to address this are:

Identify the Source of Disturbance:

- Look for another control loop exhibiting oscillations of the same amplitude. This loop is often upstream in the process. For example, resolving a pressure control issue in one column of a butadiene plant may stabilize solvent exchange in a downstream column.

Systematic Tuning:

- Perform loop tuning systematically, starting from the upstream process and working toward the affected loop.

- Adjust related control loops from the outermost to the innermost layer.

Increase Proportional Action:

- If the source of the disturbance cannot be eliminated, strengthen proportional action in the affected loop to counteract the disturbance.

Case 3: Oscillations Remain Unchanged in Manual Mode

When the oscillations persist with little change in manual mode, the issue could be due to measurement noise or insufficient control action. The steps to resolve this are:

Apply Filtering:

- Introduce or increase signal filtering to reduce the impact of noise.

Strengthen Proportional Action:

- Multiply the proportional gain by at least three and observe the oscillation behavior.

- If the oscillation amplitude does not increase, continue to strengthen proportional action until stability is achieved.

Practical Considerations

The simple rule “Proportional Action Reduces In-Phase Oscillations” is a helpful starting point but applies primarily to single-loop systems. When tuning control parameters in practice, it is crucial to:

- Maintain a global and systematic perspective.

- Tailor solutions to the specific root cause and process conditions.

- Be bold yet meticulous when making adjustments. Small parameter changes are often insufficient, so more significant adjustments may be necessary to observe meaningful effects.

Conclusion

Although the three principles for handling in-phase oscillations provide a systematic framework, they may not resolve every situation. Challenges could arise from inadequate parameter adjustments or more complex system interactions. Engineers must adapt their approach to the unique circumstances of each problem.

Finally, consider this scenario: if the controller output peaks while the process variable is neither near the setpoint nor at its own peak but somewhere in between, how would you address it? Reflecting on this question can help further deepen your understanding of control system behavior.