In industries like chemical, light, heavy, energy, agriculture, and environmental protection, water resources and their measurement are crucial. Choosing the correct flowmeter for liquid measurement depends on the liquid’s properties and the operational requirements. Below, we outline the most suitable flowmeter options based on the liquid’s nature and usage scenarios.

General Options for Measuring Water

Several flowmeters are suitable for measuring water, such as electromagnetic flowmeters, turbine flowmeters, vortex flowmeters, orifice flowmeters, ultrasonic flowmeters, and gear flowmeters. However, variations in water properties, such as pH levels, corrosiveness, and the presence of particulates, require careful consideration of the application.

Flowmeter selection plays a critical role in ensuring accuracy and reliability. Here’s a detailed guide on choosing flowmeters based on the properties of the liquid.

1. Electroplating Wastewater or Chemical Sewage

- Recommended Flowmeters: Electromagnetic Flowmeter, Ultrasonic Flowmeter

Electroplating wastewater and chemical sewage often contain corrosive substances or suspended solids. Here’s how these flowmeters perform:

Electromagnetic Flowmeter

- Advantages:

- High accuracy and stability.

- No moving parts, making it resistant to wear and blockage.

- Suitable for conductive liquids with solid particles (e.g., slurry).

- Material Options:

- For highly corrosive liquids, use electrodes made of titanium (Ti), tantalum (Ta), or platinum (Pt).

- Linings can also be chosen based on corrosiveness and temperature.

- Limitations:

- Cannot measure liquids with low conductivity, such as oils or pure water.

Ultrasonic Flowmeter

- Advantages:

- Easy installation, especially for retrofitted systems, as it can be mounted externally without cutting pipes.

- Ideal for large-diameter pipelines and conductive liquids.

- Limitations:

- Not suitable for measuring highly corrosive liquids like strong acids and bases.

2. High-Purity Water, Deionized Water, or Sugar Solutions

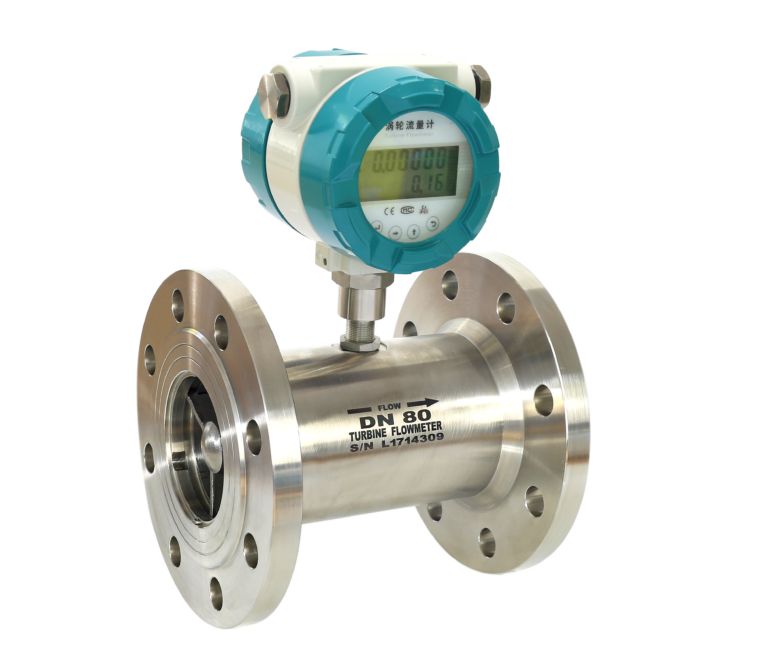

- Recommended Flowmeter: Turbine Flowmeter

Turbine flowmeters are highly effective for clean, low-viscosity liquids due to their specific design.

Advantages:

- Compact and lightweight structure, easy to install and maintain.

- Best suited for measuring pure water, organic liquids, and low-viscosity oils.

- Provides high accuracy for clean fluids.

Limitations:

- Not recommended for viscous liquids, corrosive fluids, or those containing particulates.

3. High-Viscosity Liquids

- Recommended Flowmeter: Gear Flowmeter

For high-viscosity liquids like glue, heavy oil, syrup, or resins, gear flowmeters (such as oval or circular gear models) are ideal.

Advantages:

- Works well with both low- and high-viscosity fluids.

- Newly designed models with Teflon (PTFE) linings provide excellent corrosion resistance.

- High repeatability and precision for thick or sticky liquids.

Applications:

- Frequently used in industries dealing with adhesives, lubricants, and food products like syrup or yogurt.

4. Liquids Containing Bubbles or Particles

- Recommended Flowmeter: Doppler Ultrasonic Flowmeter

This flowmeter is designed for liquids with suspended particles or entrained gas bubbles, offering reliable performance in challenging conditions.

Summary Table: Liquid Types and Suitable Flowmeters

| Liquid Type | Recommended Flowmeter | Key Considerations |

|---|---|---|

| Electroplating Wastewater | Electromagnetic, Ultrasonic | Corrosiveness, conductivity, presence of solids |

| High-Purity Water | Turbine | Cleanliness, low viscosity |

| Sugar Solutions | Turbine | Low viscosity, clean fluid |

| High-Viscosity Liquids | Gear | Viscosity, potential corrosion |

| Liquids with Bubbles | Doppler Ultrasonic | Presence of bubbles or suspended solids |

Key Parameters to Consider

While liquid properties are critical for selecting a flowmeter, other factors must also be considered:

- Pipeline Diameter: Match the flowmeter to the pipeline’s size for optimal accuracy.

- Temperature and Pressure: Ensure the flowmeter’s materials and components withstand operating conditions.

- Flow Range: Select a model with a suitable range to avoid inaccuracies.

Conclusion

Choosing the right flowmeter ensures long-term operational stability and accuracy. By understanding the properties of the liquid and the application’s requirements, you can make an informed decision. If unsure, consult a professional to evaluate all relevant parameters before purchasing.