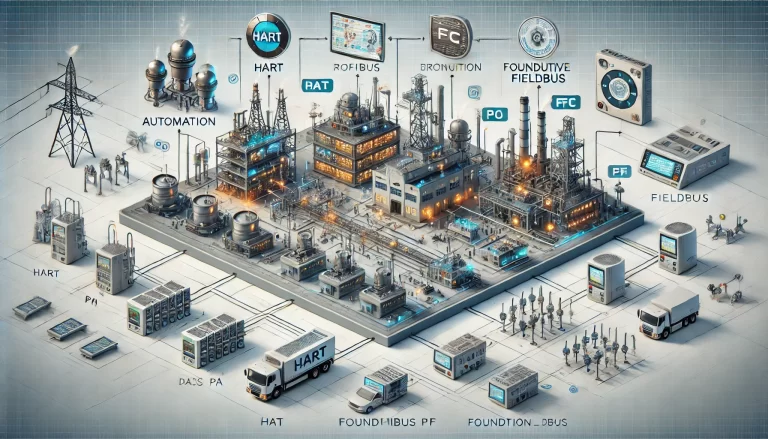

The HART (Highway Addressable Remote Transducer) protocol is a hybrid communication protocol widely used in industrial automation. By combining analog and digital communication, HART facilitates seamless integration of smart devices into traditional control systems. This article delves into the working principles of the HART protocol, its advantages, limitations, and applications across various industries.

Principles of the HART Protocol

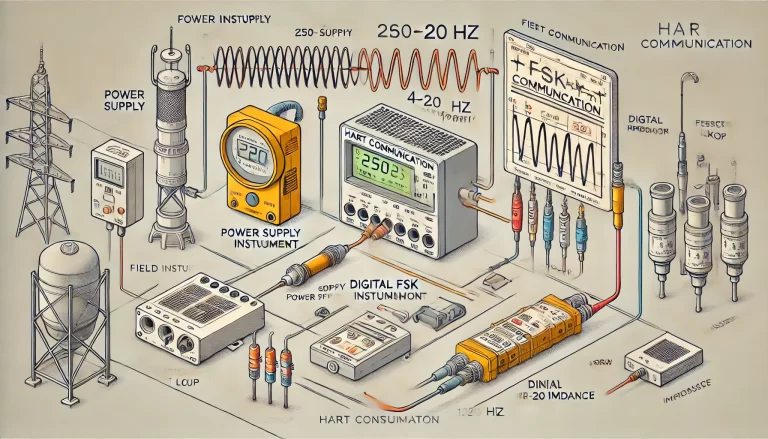

The HART protocol was developed to enhance the functionality of the ubiquitous 4-20mA current loop, a standard communication method in industrial automation. Here’s how it works:

1. Dual-Signal Transmission

HART allows for the simultaneous transmission of two signals over the same 4-20mA loop:

- Analog Signal (4-20mA): This represents the primary process variable (e.g., pressure, temperature) and is used by traditional systems.

- Digital Signal: Overlaid on the analog signal using Frequency Shift Keying (FSK) modulation, the digital signal transmits additional device data, such as configuration parameters, diagnostics, and status information.

This dual-mode operation ensures backward compatibility while offering advanced capabilities.

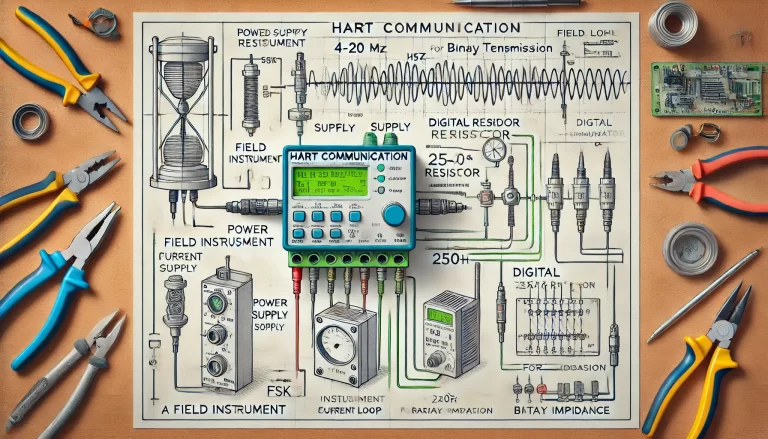

2. Frequency Shift Keying (FSK) Modulation

The HART protocol employs the Bell 202 standard FSK modulation for digital communication. It operates as follows:

- 1200 Hz represents a binary “1”.

- 2200 Hz represents a binary “0”.

Since the digital signal is superimposed on the analog current loop, it does not interfere with the analog measurement, maintaining the integrity of the primary process variable.

3. Communication Modes

HART supports two communication modes:

- Point-to-Point Mode: A single master (e.g., control system, handheld device) communicates with one slave device (e.g., sensor, actuator).

- Multidrop Mode: A master communicates with multiple slave devices, reducing wiring complexity in installations with many devices. In this mode, the current is fixed at 4mA for all devices.

4. Master-Slave Architecture

HART uses a master-slave architecture for communication:

- Master: The control system, handheld communicator, or host computer.

- Slave: The field device, such as a pressure transmitter or valve controller.

The master initiates communication, and the slave responds, ensuring orderly and reliable data exchange.

Advantages of the HART Protocol

Backward Compatibility

HART operates over the existing 4-20mA infrastructure, making it cost-effective for upgrading traditional systems without requiring new wiring.Digital Communication

The ability to transmit rich, actionable data in addition to the primary process variable enables advanced diagnostics, configuration, and device monitoring.Reliable and Robust

The FSK modulation method is resistant to noise and interference, ensuring stable communication in harsh industrial environments.Low Implementation Cost

Utilizing existing wiring and infrastructure significantly reduces costs associated with device installation and system upgrades.Ease of Configuration and Diagnostics

Engineers can use HART-compatible handheld devices or software tools to configure field devices remotely, reducing downtime and maintenance costs.

Limitations of the HART Protocol

Limited Data Rate

HART operates at a data rate of 1200 bits per second, which is sufficient for many applications but inadequate for high-speed or large-volume data transfer.Multidrop Limitations

In multidrop mode, the number of devices is typically limited to 15, restricting scalability in large systems.Requires Specialized Tools

Configuration and troubleshooting often require HART-specific tools or software, which can introduce additional costs and complexity.

Applications of the HART Protocol

1. Process Control

HART is widely used for monitoring and controlling process variables like pressure, temperature, flow, and level. The analog signal provides real-time data to control systems, while the digital signal offers advanced diagnostics.

2. Predictive Maintenance

By transmitting diagnostic data from field devices, HART enables predictive maintenance. Engineers can detect potential issues, such as sensor drift or valve wear, before they lead to system failures.

3. Field Device Configuration

HART simplifies the configuration of field devices, such as setting ranges for sensors or adjusting valve parameters, without requiring manual intervention.

4. Calibration and Testing

Technicians can use HART handheld communicators or software tools to calibrate and test devices in the field, ensuring accuracy and reliability.

Industry Use Cases

Oil and Gas

- Pressure and temperature monitoring in pipelines.

- Remote configuration of devices in hazardous environments.

Chemical Processing

- Monitoring and controlling reactor conditions.

- Ensuring safe operation through continuous diagnostics.

Water and Wastewater

- Measuring flow rates and water levels.

- Managing pump and valve operations efficiently.

Power Generation

- Monitoring boiler conditions.

- Ensuring the reliability of turbines through device diagnostics.

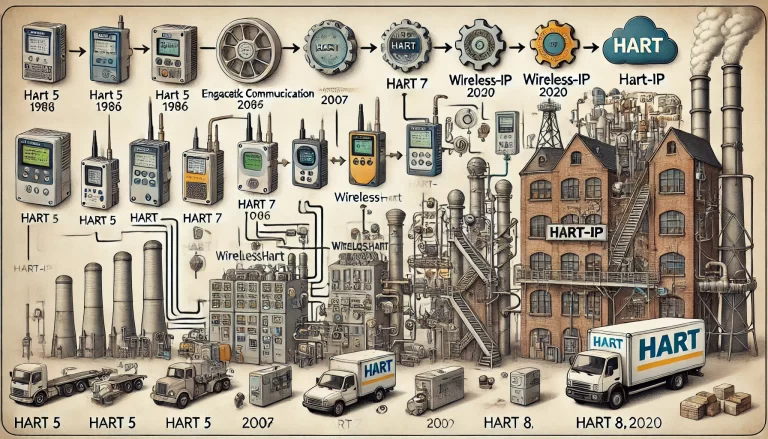

Future of the HART Protocol

While HART remains a trusted protocol in industrial automation, newer technologies like WirelessHART and IoT-based solutions are building on its foundation to meet evolving industry needs. WirelessHART, for instance, eliminates wiring constraints, enabling greater flexibility and scalability in industrial networks.

Conclusion

The HART protocol strikes a balance between legacy compatibility and modern digital communication, making it a versatile solution for industrial automation. Its ability to transmit rich data over existing infrastructure reduces costs and enhances operational efficiency. Despite its limitations, the protocol continues to be a critical tool for ensuring reliable and efficient process control across industries.