Maintenance management in the instrumentation industry is a specialized field that focuses on ensuring the accuracy, reliability, and functionality of measurement and control devices. Given the critical role of these instruments in sectors like manufacturing, healthcare, energy, and aerospace, a systematic approach to maintenance is essential. This article details the key aspects of maintenance management tailored to the instrumentation industry.

1. Maintenance Planning and Scheduling

Periodic Calibration Plans

- Instruments must undergo regular calibration to maintain their precision. Calibration intervals are defined based on usage frequency, environmental conditions, and industry regulations (e.g., ISO 17025, NIST standards).

- A detailed calibration schedule should account for all instruments in operation, including their calibration history and upcoming due dates.

Preventive Maintenance Plans

- Define a preventive maintenance (PM) schedule for cleaning, inspecting, and replacing worn components before failure occurs.

- Tailor PM tasks based on the instrument type, such as sensors, transmitters, or controllers.

Emergency Maintenance Plans

- Develop a protocol for handling instrument failures that impact critical operations. Ensure quick access to spare parts and a team for emergency repairs.

2. Maintenance Execution and Workflow

Task Breakdown

- External Inspection: Check for physical damage, wear, corrosion, or contamination.

- Internal Diagnostics: Test internal circuits, sensors, and connectors for functionality and accuracy.

- Calibration: Use certified calibration equipment to verify and adjust the instrument’s accuracy within acceptable limits.

- Software Updates: For smart or IoT-enabled instruments, ensure firmware and software are updated.

Documentation During Execution

- Record calibration adjustments, replaced parts, and any issues found. Use standardized formats for consistency.

Testing and Validation

- After repairs or adjustments, validate the instrument’s performance using reference standards or comparison with baseline readings.

3. Quality Management

Defining Quality Standards

- Ensure maintenance aligns with international standards like ISO 9001 for quality management systems and ISO 10012 for measurement management.

Calibration Traceability

- Maintain traceability to national or international standards through calibration certificates.

Quality Audits

- Conduct regular internal audits to verify that instruments and processes meet compliance and operational requirements.

4. Equipment and Spare Parts Management

Inventory Management

- Maintain a centralized database for spare parts, including sensors, connectors, and calibration tools. Stock frequently used items to avoid downtime.

Equipment Tagging

- Use barcodes or RFID tags to track instrument usage, calibration status, and maintenance history.

Lifecycle Management

- Monitor instrument performance trends to decide when to refurbish or replace devices nearing the end of their lifecycle.

5. Personnel and Training

Skilled Workforce

- Ensure maintenance personnel have certifications relevant to their roles, such as metrology or electronics engineering.

Ongoing Training

- Offer specialized training on new instrumentation technologies, calibration techniques, and industry standards.

Responsibility Assignment

- Clearly define roles for tasks such as diagnostics, calibration, documentation, and approvals.

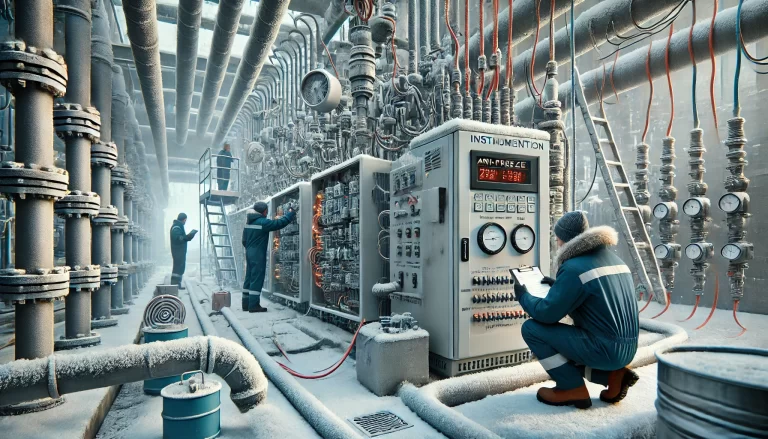

6. Safety and Environmental Control

Static Protection

- Use anti-static equipment and protocols to prevent damage to sensitive electronic components.

Hazard Mitigation

- Follow electrical safety standards when working with powered instruments. Use insulated tools and personal protective equipment (PPE).

Controlled Environment

- Perform maintenance in clean rooms or low-dust environments for precision instruments sensitive to contaminants.

7. Post-Maintenance Evaluation

Performance Monitoring

- Use automated data logging systems to track instrument performance after maintenance.

Drift Analysis

- Analyze calibration records to identify instruments prone to drift and adjust maintenance schedules accordingly.

Feedback Integration

- Collect feedback from instrument users to identify potential areas for improving maintenance processes.

8. Digital and Information Management

Computerized Maintenance Management Systems (CMMS)

- Use CMMS software to plan, schedule, and track maintenance activities. The system should allow for easy retrieval of calibration records and instrument histories.

Data Analytics

- Analyze historical data to identify recurring issues and predict potential failures using trend analysis.

IoT Integration

- Leverage IoT-enabled instruments to receive real-time diagnostics and alerts, enabling predictive maintenance.

9. Regulatory Compliance

Adherence to Standards

- Ensure maintenance procedures comply with applicable standards, such as:

- ISO 17025 for calibration laboratories.

- FDA and GMP for medical and pharmaceutical instruments.

- JJG standards in China for legal metrology.

Third-Party Validation

- Periodically engage accredited calibration service providers to verify internal calibration processes.

10. Special Considerations for Instrument Types

Pressure Instruments

- Inspect and clean pressure lines. Calibrate using certified pressure standards. Replace worn diaphragms or sensors.

Flow Meters

- Check for blockages, ensure the flow path is clean, and recalibrate with flow calibration rigs.

Temperature Sensors

- Inspect thermocouples and RTDs for physical damage. Use certified temperature baths for calibration.

Electrical Meters

- Verify the accuracy of voltage, current, and resistance measurements using standard electrical sources.

Conclusion

Effective maintenance management in the instrumentation industry ensures accurate and reliable measurements, minimizes downtime, and complies with industry regulations. A robust strategy combines meticulous planning, skilled personnel, precise execution, and advanced technology to achieve long-term operational excellence. By adhering to these principles, organizations can enhance productivity, safety, and overall performance in critical operations.