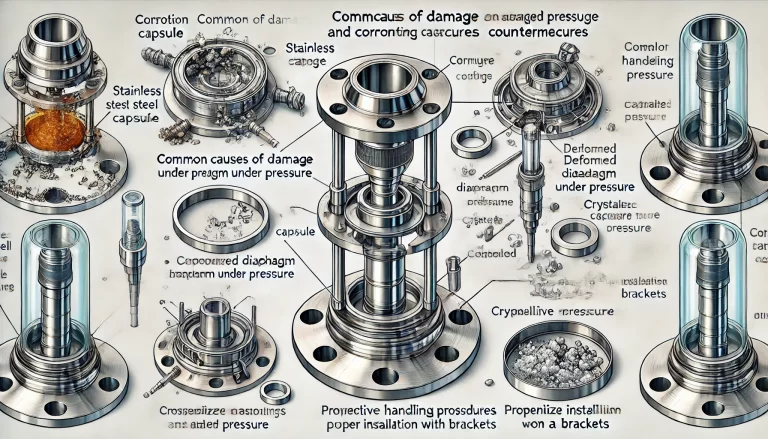

Double-flange capsule assemblies are widely used in various industrial applications for precise measurements under complex working conditions. However, their performance can be compromised by damage caused by several factors. This article identifies the common causes of damage and provides detailed countermeasures to ensure optimal functionality and longer service life.

1. Corrosion

Cause:

Corrosion occurs when the chemical properties of the process medium interact with the capsule material. For instance, high-temperature and high-pressure gases containing hydrogen molecules (H₂) and chloride ions (Cl⁻) can lead to hydrogen embrittlement and material degradation in 316L stainless steel capsules. If the chosen diaphragm material is incompatible with the medium, the rate of corrosion accelerates.

Countermeasures:

- Material Selection: Choose capsule materials compatible with the process medium. For example, replace 316L capsules with tantalum capsules for enhanced corrosion resistance.

- Preventive Maintenance: Regularly inspect for signs of corrosion and replace damaged capsules promptly.

- Protective Coatings: Apply specialized coatings or linings to capsules to improve resistance to corrosive environments.

2. Mechanical Damage

Cause:

Capsules can sustain mechanical damage during handling, installation, or operation. External forces such as impacts or collisions may cause deformation or rupture. Additionally, frequent start-stop operations in certain processes may induce stress variations, leading to tearing of the diaphragm.

Countermeasures:

- Careful Handling: Avoid applying external forces to capsules during installation or transport. Use protective packaging where necessary.

- Installation Guidelines: Ensure that capillaries are placed away from high-temperature areas such as heat tracing pipelines.

- Enhanced Design: Use more robust diaphragm structures, such as flat diaphragms, to replace insertion-type designs in environments prone to mechanical stress.

3. Temperature and Pressure Effects

Cause:

When operating under negative pressure, the capsule’s diaphragm may bulge outward due to vacuum effects, reducing internal system pressure and causing fill fluid evaporation. High-temperature environments can also lead to capsule deformation or bulging.

Countermeasures:

- Optimized Installation: Position the instrument below the flange level to minimize the effects of negative pressure.

- Preventive Inspections: Conduct regular maintenance to detect and replace capsules deformed by high temperatures or pressure changes.

- Upgraded Equipment: In extreme conditions, consider using high static pressure double-flange liquid level transmitters for improved durability and reliability.

4. Capillary Tube Damage

Cause:

Capillary tubes are susceptible to damage caused by lifting, impacts, or exposure to high temperatures, which may result in silicone oil leakage and failure of the capsule assembly.

Countermeasures:

- Protective Measures: Never lift double-flange assemblies by their capillary tubes. After installation, secure the tubes with protective brackets.

- High-Temperature Avoidance: Ensure capillary tubes are installed away from high-temperature regions to prevent heat-induced damage.

- Routine Monitoring: Inspect the condition of capillary tubes regularly and replace them when signs of wear or damage appear.

5. Contamination and Crystallization

Cause:

Impurities or crystallized substances in the process medium can accumulate on the capsule diaphragm, causing unstable signal output or measurement inaccuracies.

Countermeasures:

- Heating Measures: Implement insulation or heating for process mediums prone to crystallization at low temperatures.

- Regular Cleaning: Clean the capsule assembly periodically to maintain a clear diaphragm surface.

- Additional Features: Install flushing rings and introduce cleaning mediums to prevent the buildup of residues or crystallized substances on the diaphragm.

6. Proactive Detection and Monitoring

Additional Recommendations:

To avoid unexpected failures, utilize advanced non-destructive testing techniques, such as ultrasonic or eddy current inspections, to detect early-stage damage in capsules or related components. Integrating these tests into routine maintenance schedules can help identify problems before they escalate.

Conclusion

Understanding the causes of damage to double-flange capsule assemblies and implementing appropriate countermeasures can significantly improve their reliability and lifespan. By focusing on proper material selection, careful handling, preventive maintenance, and equipment upgrades, industries can reduce downtime and maintain accurate measurements even under challenging conditions.