Hydrogen is emerging as a key player in the future of clean energy. However, the safe handling of this highly flammable gas requires a clear understanding of detection technologies and associated risks. Misconceptions around hydrogen detection can lead to hazardous oversights. This article aims to clarify these issues by dispelling three common myths, explaining key detection technologies, and providing a detailed guide on implementing an effective layered detection system.

Common Misconceptions about Hydrogen Detection

Myth 1: Human Senses Can Detect Hydrogen Leaks

Fact: Hydrogen is colorless, odorless, and tasteless, making it completely undetectable by human senses. Even its flame is nearly invisible, posing a severe risk of delayed detection during a fire.

Correct Approach: Professional detection systems, such as ultrasonic leak detectors, gas concentration sensors, and flame detectors, are essential. These technologies work together to create a multi-tiered monitoring network for comprehensive safety.

Myth 2: A Single Detector Solves All Problems

Fact: No single detection technology can address all scenarios. For instance, ultrasonic detectors are highly sensitive to high-pressure leaks but ineffective for low-concentration accumulations. Similarly, point gas detectors offer high precision but respond more slowly in dynamic environments.

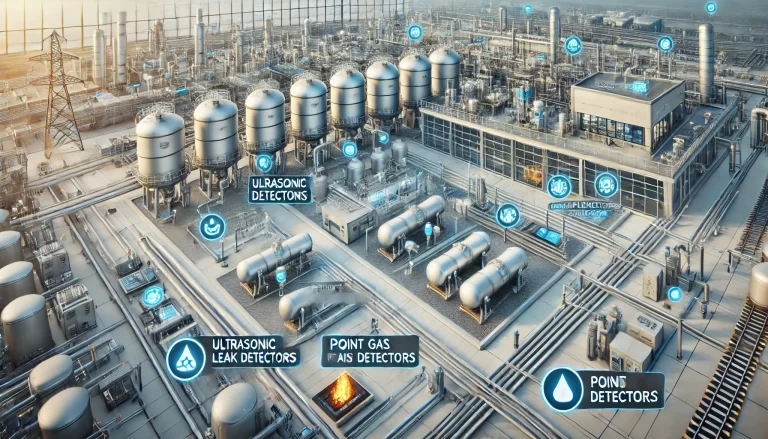

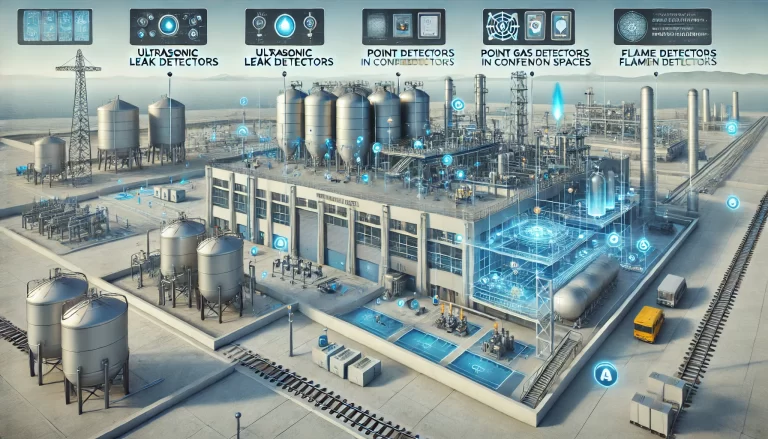

Correct Approach: Use a combination of detection technologies, each suited for specific conditions. For example:

- Ultrasonic detectors: Ideal for high-pressure leaks.

- Point detectors: Accurate for monitoring localized gas concentrations.

- Flame detectors: Crucial for identifying fires from hydrogen combustion.

Myth 3: Installing Detectors Guarantees Safety

Fact: Proper placement and maintenance are critical for effective detection. Even the best detectors can fail if not positioned in high-risk areas, such as pipe joints and valves, or if calibration lapses occur over time.

Correct Approach: Plan detector layouts strategically based on risk assessment and environmental factors. Regular calibration and maintenance are mandatory to ensure accuracy.

The Science Behind Hydrogen Detection

To understand hydrogen detection better, let’s explore three core principles: “Listening,” “Smelling,” and “Seeing.”

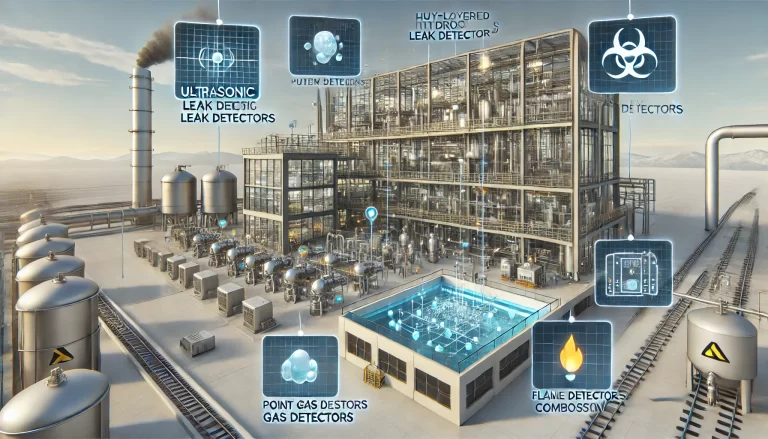

Listening

- Technology: Ultrasonic leak detectors identify sound waves (above 20 kHz) produced by leaking gas.

- Limitations: Ineffective for low-pressure or minor leaks.

Smelling

- Technology: Point gas detectors measure gas concentration using techniques like catalytic combustion (for high concentrations) or electrochemical sensors (for low concentrations).

- Limitations: Slower response times and difficulty monitoring large areas.

Seeing

- Technology: Flame detectors use infrared or ultraviolet sensors to detect radiation emitted during hydrogen combustion. Water molecules generated by burning hydrogen emit specific infrared wavelengths, which these detectors identify.

- Limitations: Suitable only for post-combustion scenarios, offering no pre-leak warnings.

The Key: Combine these technologies to cover the entire spectrum, from early leak detection to fire monitoring.

Deploying a Layered Detection System

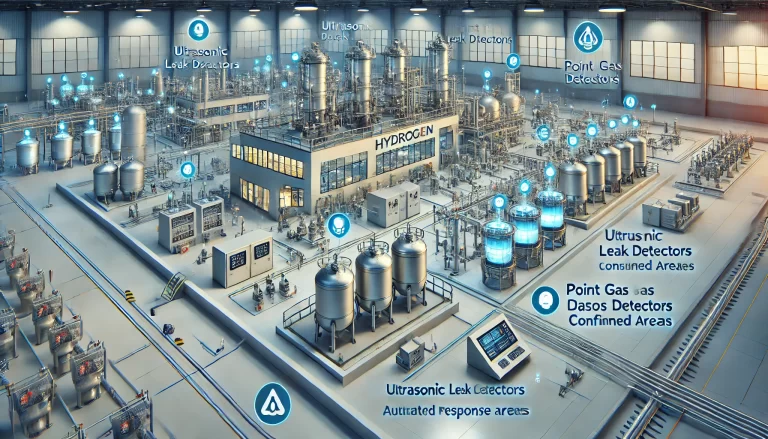

To ensure comprehensive hydrogen safety, a multi-layered detection system is essential. Here’s a logical approach:

Layer 1: Rapid Detection

Install ultrasonic leak detectors in high-pressure zones to identify leaks instantly.

Layer 2: Precise Monitoring

Place point gas detectors in areas where gas might accumulate, such as confined spaces or low-ventilation zones.

Layer 3: Fire Detection

Deploy flame detectors in high-risk zones to identify invisible flames during hydrogen combustion.

Layer 4: Integrated Control

Integrate signals from all detectors into an automated control system capable of triggering quick responses, such as closing valves, activating ventilation, or initiating fire suppression systems.

Detection is Just the Beginning: The Role of Response Mechanisms

Detection is only one part of the safety equation. A comprehensive hydrogen safety system must include robust response mechanisms. Here are three key considerations:

Action Plans Post-Detection

- Establish clear protocols for immediate responses, such as shutting off valves or activating fire suppression systems.

- Conduct regular emergency drills to ensure personnel are familiar with response procedures.

Preventing False Alarms

- False alarms disrupt operations and may lead to desensitization over time. Use multiple detection technologies in tandem to validate alerts and minimize false positives.

Ensuring Long-Term Reliability

- Regularly calibrate and maintain detectors, particularly in challenging environments with high humidity, temperature, or dust levels. Neglected equipment can degrade, leading to inaccurate readings.

Towards a Scientific Approach to Hydrogen Detection

Hydrogen detection is not a one-size-fits-all solution. It requires a scientific understanding of detection technologies, strategic deployment, and dynamic response mechanisms. By moving beyond misconceptions and embracing layered detection strategies, stakeholders can build robust safety systems that support hydrogen’s role in a sustainable energy future.

The safety of hydrogen-based systems relies not only on technology but also on the vigilance and expertise of those implementing it. Let us work together to ensure that hydrogen remains a safe and viable energy source for generations to come.