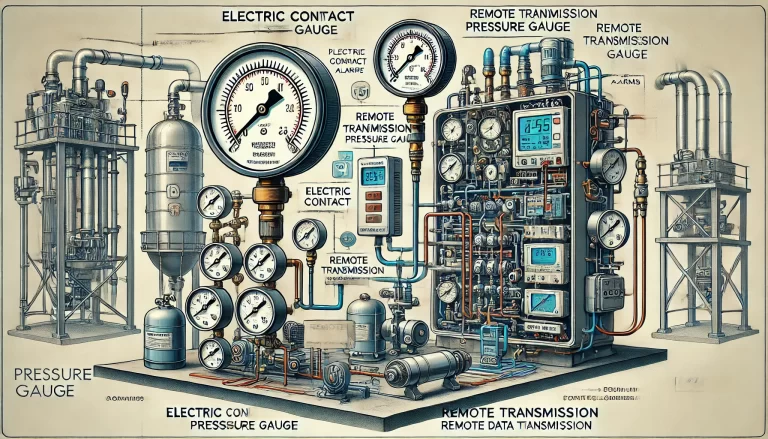

Pressure gauges are essential devices in industrial systems to monitor and manage pressure levels. Among the various types, electric contact pressure gauges and remote transmission pressure gauges stand out due to their unique features and functionalities. Despite their shared purpose of pressure measurement, they differ significantly in their principles, applications, and advantages. Below is a detailed comparison between these two types of pressure gauges.

1. Function and Purpose

Electric Contact Pressure Gauge

Electric contact pressure gauges are primarily used for local monitoring and control. They integrate a mechanical pressure gauge with an electric contact mechanism that triggers a circuit when the pressure reaches a preset limit.- Primary Function: To provide local pressure readings and activate control systems, alarms, or safety mechanisms.

- Common Applications: Boiler systems, air compressors, and hydraulic systems where maintaining pressure within a set range is crucial.

Remote Transmission Pressure Gauge

Remote transmission pressure gauges, also known as pressure transmitters, are used for remote pressure monitoring. They convert pressure readings into standard electrical signals (e.g., 4-20mA or 0-10V) for long-distance transmission to control systems like PLCs (Programmable Logic Controllers) or SCADA (Supervisory Control and Data Acquisition) systems.- Primary Function: To enable centralized monitoring and integration into automated systems.

- Common Applications: Industries requiring real-time data transmission, such as petrochemical plants, water treatment facilities, and large-scale industrial automation.

2. Design and Structure

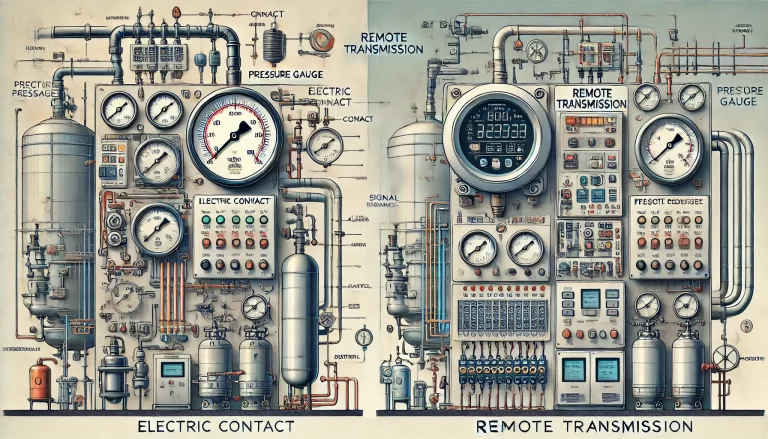

Electric Contact Pressure Gauge

This gauge combines a traditional mechanical pressure gauge (e.g., Bourdon tube or diaphragm) with electrical contacts.- Core Components:

- A mechanical pressure sensor (e.g., Bourdon tube) to measure and display the pressure.

- Adjustable contact points that close or open an electrical circuit at preset pressure levels.

- A dial to display real-time pressure values.

- Operation: When the needle (driven by the mechanical sensor) reaches the preset contact point, the circuit is completed, triggering an alarm or activating a relay.

- Core Components:

Remote Transmission Pressure Gauge

This gauge includes a pressure sensing element and an electrical signal converter.- Core Components:

- Pressure transducers or sensors (e.g., piezoresistive, capacitive, or strain-gauge types) to detect pressure changes.

- Signal conditioning circuits to amplify and standardize the electrical output.

- Optional digital or analog displays.

- Operation: The pressure sensing element converts pressure into an electrical signal proportional to the applied force. This signal is transmitted to remote control systems.

- Core Components:

3. Working Principle

Electric Contact Pressure Gauge

- Utilizes mechanical deformation (e.g., of a Bourdon tube) to measure pressure.

- The deformation drives the pointer on the dial.

- When the pointer reaches a preset pressure level, it physically contacts an adjustable electric contact, completing the circuit and triggering an action, such as turning off a pump or sounding an alarm.

Remote Transmission Pressure Gauge

- A pressure sensing element detects pressure changes and converts them into an electrical signal.

- For example, in a strain-gauge transducer, pressure causes a deformation in the sensing element, altering its electrical resistance.

- The resulting signal is conditioned and transmitted as a standardized output (e.g., 4-20mA) for remote monitoring and control.

4. Advantages and Limitations

| Feature | Electric Contact Pressure Gauge | Remote Transmission Pressure Gauge |

|---|---|---|

| Advantages | – Simple structure and easy installation. | – Enables remote monitoring over long distances. |

| – Cost-effective for local monitoring. | – Compatible with automated control systems. | |

| – No external power source required for basic operation. | – Provides standardized outputs for industrial integration. | |

| Limitations | – Limited to local monitoring. | – Requires external power and signal processing equipment. |

| – Contact wear reduces accuracy and lifespan over time. | – Higher initial cost compared to mechanical gauges. | |

| – Not suitable for long-distance signal transmission. | – Requires calibration for precise measurements. |

5. Applications and Use Cases

Electric Contact Pressure Gauge

- Ideal for local monitoring and control in smaller systems or where automation is not a priority.

- Examples:

- Boilers: To cut off heating when pressure exceeds safe levels.

- Air Compressors: To activate/deactivate compressors based on preset pressure limits.

- Hydraulic Systems: To protect equipment by triggering alarms or shutdowns during overpressure.

Remote Transmission Pressure Gauge

- Best suited for integrated and automated systems where pressure data needs to be monitored remotely or logged continuously.

- Examples:

- Oil Refineries: Transmitting real-time pressure data to centralized control rooms.

- Water Treatment Plants: Monitoring pipe pressure remotely to ensure consistent flow.

- Industrial Automation: Feeding pressure data into PLCs for dynamic process control.

6. Key Differences at a Glance

| Feature | Electric Contact Pressure Gauge | Remote Transmission Pressure Gauge |

|---|---|---|

| Output | On/Off electrical contact signal. | Continuous analog or digital signal (e.g., 4-20mA). |

| Monitoring Range | Local monitoring only. | Suitable for remote and centralized monitoring. |

| Primary Use | Pressure control and alarms. | Data transmission for automation systems. |

| Complexity | Simple and mechanical with limited electronics. | Advanced with electronic signal processing. |

| Cost | Lower upfront cost. | Higher upfront cost due to sensors and circuits. |

Conclusion

Choosing between an electric contact pressure gauge and a remote transmission pressure gauge depends on the application’s specific needs.

- If your focus is on simple, local pressure control with minimal setup, an electric contact pressure gauge is an economical and reliable choice.

- However, if you need real-time remote monitoring or integration with automated systems, the remote transmission pressure gauge is indispensable, despite its higher cost and complexity.

Each gauge has its strengths and is best suited for particular operational scenarios, making it essential to evaluate your system requirements carefully before selecting the appropriate device.