Pressure is a critical parameter in industrial production processes, influencing both operational efficiency and safety. Accurate pressure measurement and control are essential to ensure smooth production, prevent equipment failure, and maintain workplace safety. This guide provides detailed insights into the significance of pressure measurement and practical recommendations for selecting the most suitable pressure instruments.

Importance of Pressure Measurement in Industrial Processes

Pressure monitoring plays a vital role in numerous industrial applications. For instance:

- In chemical reactions, pressure directly impacts material balance and reaction rates, requiring strict adherence to operational protocols to achieve optimal outcomes.

- In thermal power plants, furnace pressure reflects the balance between induced and forced draft airflow. Maintaining stable furnace pressure is crucial for efficient combustion and the safe, economical operation of power units.

- In safety-critical environments, pressure measurement prevents equipment damage or catastrophic failures caused by overpressure. For example, monitoring pressure in pipelines or reactors can avert explosions and production shutdowns.

Given the importance of pressure measurement, selecting the right pressure instrument is vital for process efficiency, reliability, and safety.

Key Factors in Selecting Pressure Instruments

When choosing pressure instruments, it is essential to consider the application environment, the characteristics of the measured medium, and the required performance. Below are five critical criteria to guide your selection:

1. Standard Signal Transmission

- In applications requiring data transmission and integration into automated systems, a pressure transmitter with a standard signal output (e.g., 4–20 mA) is the preferred choice. This ensures compatibility with control systems for real-time monitoring and adjustments.

2. Hazardous Environments

- For environments with flammable or explosive risks, choose either isolated explosion-proof pressure transmitters or intrinsically safe explosion-proof pressure transmitters. These devices are designed to prevent electrical sparks or heat that could ignite hazardous atmospheres.

3. Challenging Media Characteristics

- When dealing with media prone to crystallization, clogging, or corrosion, or with viscous properties, flange-mounted pressure transmitters are highly recommended. Additionally, ensure that the materials in contact with the medium are chosen based on the medium’s specific properties (e.g., stainless steel for corrosive fluids).

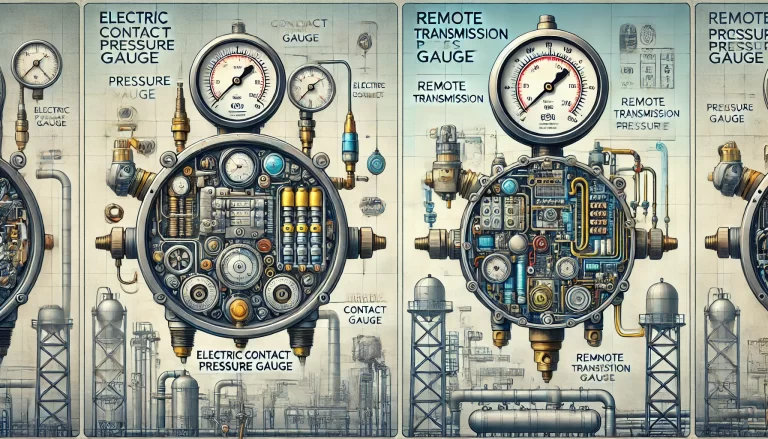

4. General Applications

- In environments with stable conditions and lower accuracy or reliability requirements, pressure gauges can be a cost-effective option. They provide a straightforward solution for basic pressure monitoring without the need for complex installations.

5. Low-Pressure Measurements

- For applications requiring the measurement of very low pressures (e.g., less than 500 Pa), a micro differential pressure transmitter is ideal. These instruments offer high sensitivity and accuracy, making them suitable for monitoring slight pressure variations.

Additional Considerations for Selection

To ensure optimal performance, the following considerations should also be taken into account:

- Temperature conditions: Verify the operating temperature range of the instrument to prevent performance degradation in extreme environments.

- Mounting and maintenance: Consider ease of installation and routine servicing. Instruments in remote or hazardous locations may require additional features, such as remote sensing capabilities.

- Budget constraints: While higher-spec instruments offer better reliability and features, they may not always be necessary. Evaluate the trade-off between cost and performance based on your operational needs.

Conclusion

The selection of pressure instruments is more than a technical decision—it directly impacts the efficiency, safety, and reliability of industrial processes. By carefully evaluating the requirements of your application and the characteristics of the instruments, you can ensure accurate pressure measurement and effective control. Whether you’re operating in a high-risk chemical plant or a stable manufacturing environment, there is a suitable pressure instrument to meet your needs.