Thermal relays are essential components in electrical systems, widely used for overload protection of motors and other electrical equipment. Their operation is based on the principle of thermal effects caused by electric current. This article delves into their working principle, structure, and practical applications, offering a comprehensive understanding of this indispensable device.

Working Principle of Thermal Relays

Thermal relays operate on the basis of the thermal effect of electric current, which is the heating caused by the passage of electric current through a conductor. Here is a detailed breakdown of their operation:

Heat Generation:

- When current flows through the heating element of the thermal relay (typically made of resistance wire or an alloy strip), it generates heat. The amount of heat produced is proportional to the square of the current (per Joule’s Law).

- If the current exceeds a preset threshold for an extended period, the heating element reaches a temperature sufficient to activate the relay.

Bimetallic Strip Mechanism:

- A bimetallic strip, which is composed of two layers of metals with different coefficients of thermal expansion, is heated by the heating element.

- The differential expansion causes the strip to bend. The greater the current, the higher the heat, and thus the greater the bending of the strip.

Actuation of the Relay:

- The bending bimetallic strip moves a mechanical linkage. When the strip bends far enough, it triggers the switching mechanism.

- The switch disconnects the load, interrupting the current flow to the protected equipment, thereby preventing overheating or damage.

Reset Mechanism:

- After the thermal relay has been tripped, it can be reset either manually (via a reset button) or automatically (when the bimetallic strip cools and returns to its original shape).

- The method of resetting depends on the design and application requirements.

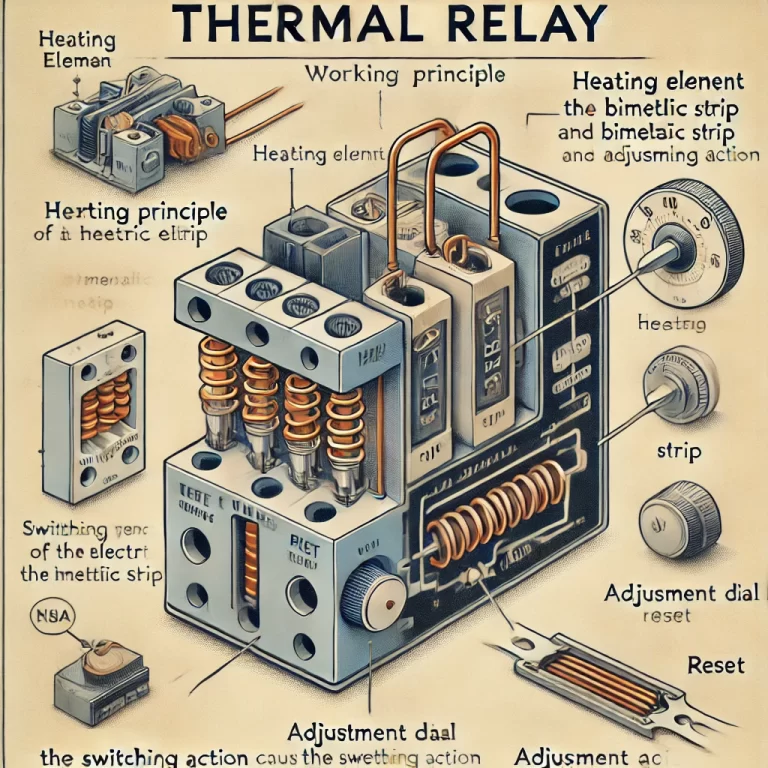

Structure of a Thermal Relay

A typical thermal relay consists of the following components:

Heating Element:

- This is the primary component responsible for generating heat when current flows through it. The heating element is typically a coil or a strip of high-resistance material.

Bimetallic Strip:

- The heart of the thermal relay, this strip bends due to heat and serves as the actuator for the relay.

Switching Mechanism:

- A mechanical system that is actuated by the bimetallic strip, it opens or closes the electrical circuit.

Adjustment Dial:

- A knob or screw allows users to set the desired current level at which the relay will trip. This enables customization for different load requirements.

Reset Mechanism:

- A manual or automatic system for restoring the relay to its operational state after tripping.

Applications of Thermal Relays

Thermal relays find applications across various domains of electrical and industrial engineering. Key uses include:

Overload Protection for Motors:

- One of the most common applications is in protecting electric motors from overload conditions. If a motor operates under excessive load, the current increases, and the thermal relay trips to prevent overheating and potential motor failure.

Overload Protection in Electrical Circuits:

- Thermal relays are used in control circuits and load circuits to protect electrical systems from prolonged overcurrent conditions.

Coordination with Circuit Breakers:

- Although thermal relays are not designed for short-circuit protection, they are often used in combination with circuit breakers or fuses. The thermal relay provides overload protection, while the breaker handles short-circuit conditions.

Automation Systems:

- In automated machinery and production lines, thermal relays are integrated into control systems to prevent damage to equipment caused by overcurrent.

Auxiliary Protection in Low-Voltage Systems:

- They are used alongside contactors in low-voltage systems, ensuring that overload conditions do not cause system failures.

Advantages and Limitations of Thermal Relays

Advantages:

- Simplicity:

- Thermal relays are mechanically simple, making them reliable and easy to maintain.

- Cost-Effectiveness:

- They are inexpensive compared to more complex protective devices like electronic relays.

- Customizable Settings:

- The current trip level is adjustable, allowing for flexibility in application.

Limitations:

- Slow Response Time:

- Thermal relays are not suitable for protecting against instantaneous faults, such as short circuits, due to their relatively slow response.

- Limited Current Range:

- They are typically used for low to moderate current applications and are unsuitable for high-power systems.

- Temperature Dependency:

- External environmental temperature variations can influence the performance and sensitivity of thermal relays.

Conclusion

Thermal relays are invaluable devices for safeguarding electrical systems from damage caused by overcurrent. Their reliance on the thermal properties of materials makes them a cost-effective and straightforward solution for many industrial and residential applications. However, their limitations necessitate their use alongside other protective devices, such as circuit breakers, for comprehensive system protection. Despite the advent of advanced electronic relays, thermal relays remain a popular choice due to their simplicity, reliability, and affordability.