When it comes to electrical interfaces in instrumentation, selecting the correct thread type is essential for ensuring reliable connections and sealing. This article explores the most common thread types, their characteristics, applications, and examples to provide a comprehensive understanding.

1. Metric Threads (M)

Metric threads, also known as ISO metric threads, are standardized by the International Organization for Standardization (ISO). Widely used across the globe, they feature a triangular thread profile with a thread angle of 60°.

Characteristics:

- Available in coarse and fine pitch.

- Do not inherently provide sealing capabilities; typically require sealing rings for a secure seal.

- Common in general mechanical fastening applications.

Specifications:

- The letter “M” indicates the thread type, followed by the nominal diameter and pitch in millimeters. For instance:

- M20×1.5: 20mm diameter with a 1.5mm pitch.

- M14×1.5: 14mm diameter with a 1.5mm pitch.

- M10×1.0: 10mm diameter with a 1.0mm pitch.

- The letter “M” indicates the thread type, followed by the nominal diameter and pitch in millimeters. For instance:

Applications:

- Frequently used in machinery, electrical equipment, and other applications requiring strong, standard connections.

2. British Standard Pipe Parallel Threads (G)

G threads are part of the Whitworth thread family and are commonly used in pipe fittings. These threads have a thread angle of 55° and are non-sealing by themselves, necessitating sealing components such as O-rings or sealing washers.

Characteristics:

- Cylindrical threads with a 55° angle.

- Specified by diameter and thread pitch in inches.

Specifications:

- Examples include:

- G1/2″: 1/2 inch diameter.

- G3/8″: 3/8 inch diameter.

- G1/4″: 1/4 inch diameter.

- Examples include:

Applications:

- Widely used in electrical cable connections and piping systems where sealing components can be added.

3. Panzer-Gewinde (PG) Threads

PG threads originate from Germany and are widely used in electrical conduit fittings. They are known for their fine pitch and self-sealing properties.

Characteristics:

- Cylindrical threads with an 80° thread angle.

- Superior sealing performance compared to metric or G threads.

Specifications:

- Common examples include:

- PG16: Used for cable diameters around 10-14mm.

- PG25: Used for cable diameters around 18-25mm.

- Common examples include:

Applications:

- Preferred for electrical cable glands and fittings requiring reliable sealing without additional components.

4. National Pipe Tapered Threads (NPT)

NPT threads are a type of tapered thread standardized by the American National Standards Institute (ANSI). They are widely used in North America for applications requiring high sealing performance.

Characteristics:

- 60° thread angle with a tapered profile.

- Provides self-sealing capabilities through thread engagement.

Specifications:

- Examples include:

- NPT1/2″: 1/2 inch diameter with 14 threads per inch.

- NPT1/4″: 1/4 inch diameter with 18 threads per inch.

- Examples include:

Applications:

- Ideal for applications in piping systems, electrical connections, and environments requiring robust sealing, such as hydraulic and pneumatic systems.

5. British Standard Pipe Tapered Threads (PT)

PT threads are part of the Whitworth thread family and are commonly used in Europe and Commonwealth countries. They are a type of tapered thread with a 55° thread angle.

Characteristics:

- High sealing performance due to tapered design.

- Follows the GB/T7306-2000 standard in China.

Specifications:

- Examples include:

- PT1/2″: Tapered thread for 1/2 inch pipe diameter.

- PT1/4″: Tapered thread for 1/4 inch pipe diameter.

- Examples include:

Applications:

- Frequently used in piping systems, hydraulic systems, and applications requiring high sealing performance.

Summary and Recommendations

Each thread type has its unique features and applications. Selecting the correct thread type depends on factors such as the required sealing performance, mechanical strength, and compatibility with existing standards. Below is a brief comparison:

| Thread Type | Thread Angle | Sealing Capability | Primary Use Case |

|---|---|---|---|

| Metric (M) | 60° | Requires sealing rings | General mechanical fastening |

| G | 55° | Requires sealing rings | Electrical cable and pipe fittings |

| PG | 80° | Self-sealing | Electrical cable glands |

| NPT | 60° | Self-sealing | Hydraulic and pneumatic systems |

| PT | 55° | Self-sealing | High-sealing piping and fluid systems |

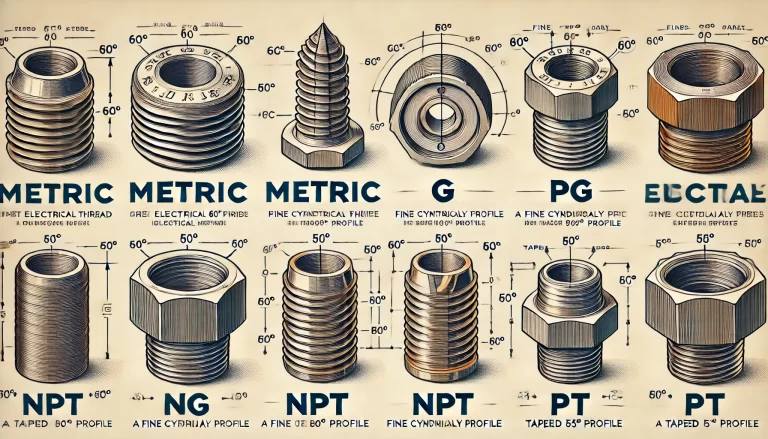

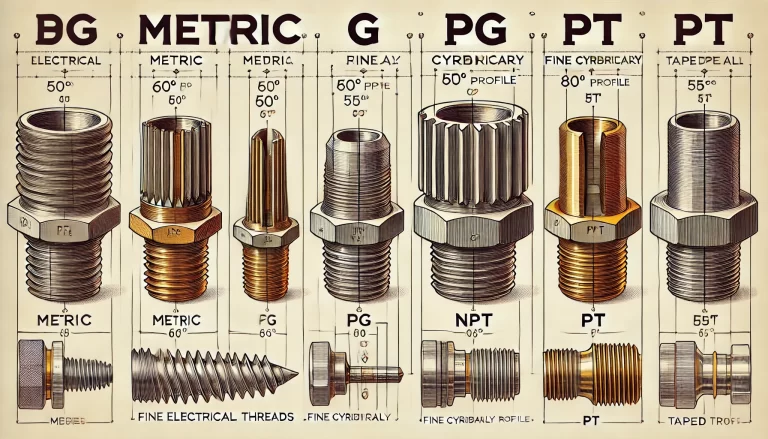

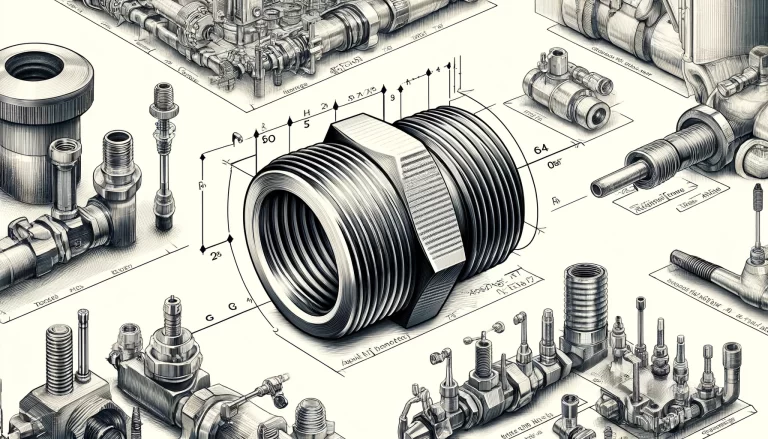

Visual Aids

To enhance clarity, adding diagrams or visual representations of the thread profiles and application examples would be beneficial. For instance:

- Illustrations showing the difference between tapered and parallel threads.

- A chart displaying common thread sizes and their applications.

With this detailed understanding, you can confidently choose the appropriate thread type for your instrumentation and ensure optimal performance and reliability.