Contactors and relays are two essential components in electrical control systems. While they share similar working principles and both function as switches controlled by an electromagnetic coil, they differ significantly in their applications, design, and capacity. Below is a detailed explanation of their differences and specific use cases.

1. Function and Purpose

Contactors

- Primary Use: Contactors are designed for switching high-power circuits. Their primary role is to control the flow of electricity to large electrical loads such as motors, heaters, compressors, and industrial lighting systems.

- Specialization: They are optimized to handle high currents and frequent switching in power circuits, making them suitable for industrial automation and heavy machinery control.

Relays

- Primary Use: Relays are intended for low-power control circuits. They are used to switch small loads, provide logic control, or isolate signals in electronic and electrical systems.

- Specialization: Relays excel in applications requiring control of signals or low-current devices, such as timers, alarms, and small actuators.

2. Current Handling Capacity

- Contactors: Designed for high current loads, contactors can handle currents ranging from a few tens to several thousand amperes. Their contacts are robust and durable, capable of withstanding high inrush currents and continuous operation.

- Relays: Typically used for low current loads, relays operate within a range of milliamperes to a few amperes. Their contacts are smaller and not suited for high-power applications.

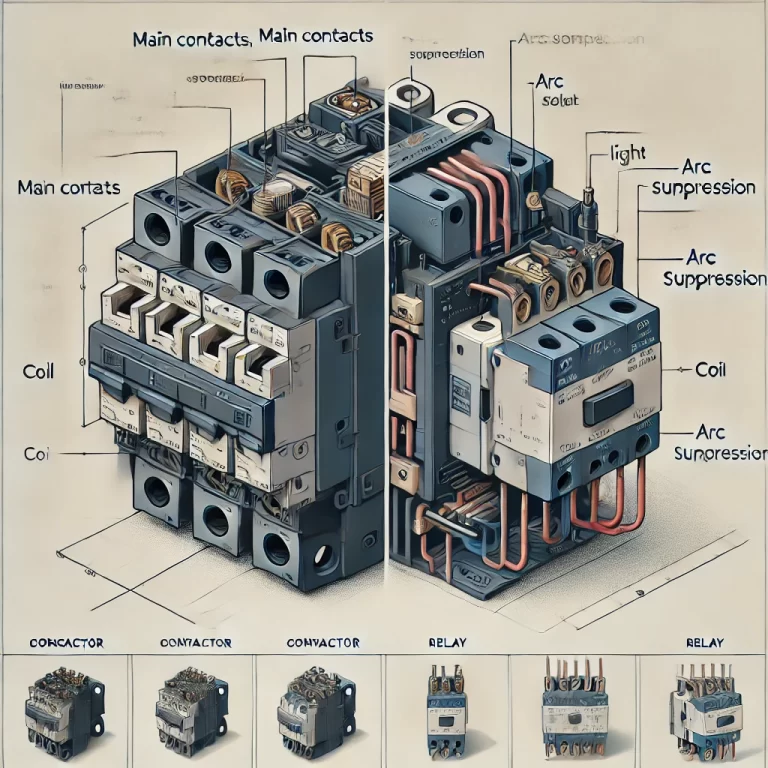

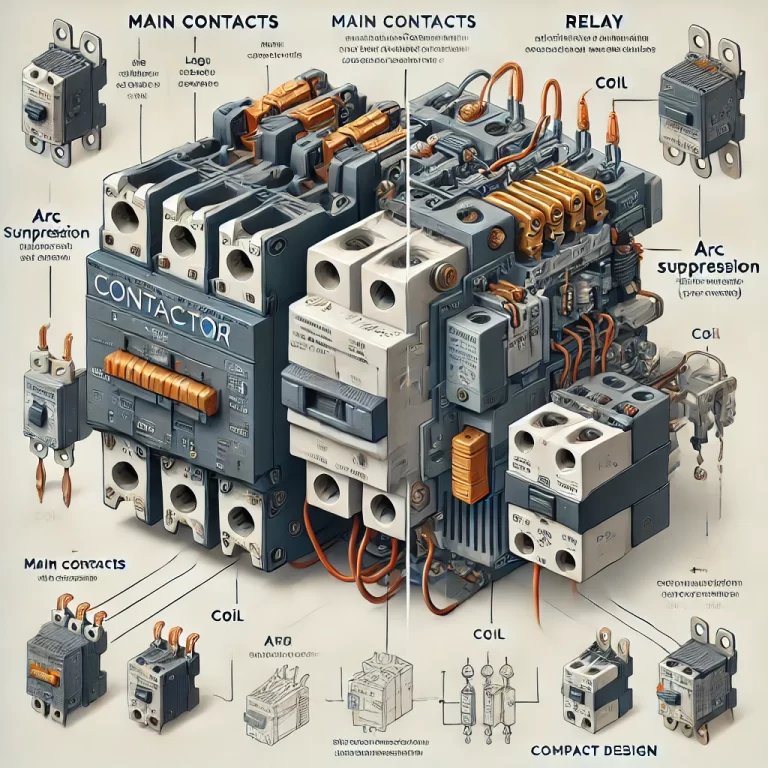

3. Structural Design

Contactors

- Contact Arrangement: Contactors usually have two types of contacts:

- Main Contacts: These carry the main load and are designed to handle large currents.

- Auxiliary Contacts: These are used for control circuit signaling or interlocks.

- Arc Suppression: Contactors are equipped with arc extinguishing mechanisms, such as arc chutes or grids, to safely manage the electrical arcs produced during the switching of high-power loads.

- Size and Durability: Contactors are generally larger and more rugged than relays, as they are designed for industrial environments where reliability under heavy loads is critical.

Relays

- Contact Arrangement: Relays typically have one or more sets of small contacts, often in single-pole or double-pole configurations, for switching low-power circuits.

- No Arc Suppression: Relays do not include arc suppression systems, as they are not designed to handle significant electrical arcs.

- Compact Design: Relays are smaller and more lightweight, often mounted on printed circuit boards (PCBs) or housed in compact enclosures.

4. Operating Voltage and Coil Design

Contactors:

- The control coils in contactors are often designed to operate at industrial voltages, such as 110V AC, 220V AC, or 380V AC, though low-voltage options (e.g., 24V DC) are also available.

- Contactors are engineered for frequent operation, withstanding thousands of on/off cycles without significant wear.

Relays:

- Relays typically operate on low control voltages, such as 5V DC, 12V DC, or 24V DC, making them compatible with electronic circuits.

- They are not designed for high-frequency switching, as frequent operation can lead to faster degradation of the contacts.

5. Applications

Contactors

- Industrial Control Systems: Contactors are widely used in factories and automation systems to control large electric motors, conveyor belts, and industrial heaters.

- High-Power Lighting Systems: They are employed in commercial or stadium lighting systems where high-power switching is required.

- Load Isolation: Contactors are often used as safety devices to isolate high-voltage equipment from the power source.

Relays

- Signal Control: Relays are commonly used in low-power electronic circuits for switching signals and implementing logic operations.

- Home Appliances: In devices like washing machines, microwaves, and refrigerators, relays control smaller components such as solenoids or fans.

- Automotive Systems: Relays are used to control headlights, wipers, and other electrical systems in vehicles.

- Protective Functions: Relays are essential in protection schemes for circuits, such as overcurrent or undervoltage protection.

6. Key Differences at a Glance

| Feature | Contactors | Relays |

|---|---|---|

| Primary Purpose | High-power switching | Low-power control |

| Current Capacity | High (up to thousands of amperes) | Low (milliamperes to a few amperes) |

| Contact Design | Robust, includes arc suppression | Small, no arc suppression |

| Size and Durability | Larger, industrial-grade | Smaller, for compact applications |

| Control Voltage | Higher, often AC | Lower, often DC |

| Switching Frequency | High, frequent switching | Moderate to low |

7. Selection Criteria

When deciding between a contactor and a relay, consider the following factors:

- Load Power: For high-power loads like motors or industrial equipment, use a contactor. For low-power loads like control signals, use a relay.

- Frequency of Operation: Contactors are better suited for frequent switching. Relays are more appropriate for occasional switching.

- Size Constraints: If space is limited, relays are often a better choice due to their compact design.

- Application Environment: Contactors are designed for harsh industrial environments, while relays are better for electronics and home appliances.

Conclusion

Both contactors and relays play vital roles in modern electrical systems, but their differences make them suited to distinct applications. Understanding their capabilities and limitations ensures proper selection and optimal system performance. For high-power, industrial-grade tasks, a contactor is the go-to device. For low-power, signal-level operations, relays are the ideal choice.