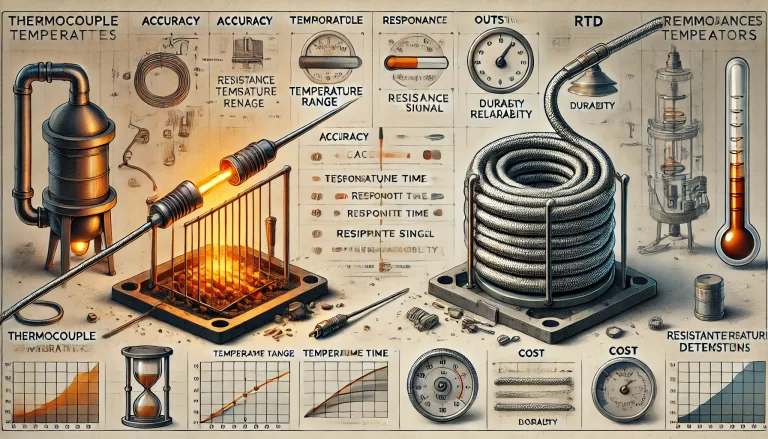

Resistance Temperature Detectors (RTDs) are widely used for temperature measurement in industrial and laboratory settings. RTDs rely on the principle that the electrical resistance of certain materials, such as platinum or copper, changes predictably with temperature. Among the most common RTDs are Pt100 and Pt1000, named after their resistance values of 100 Ω and 1000 Ω at 0°C, respectively.

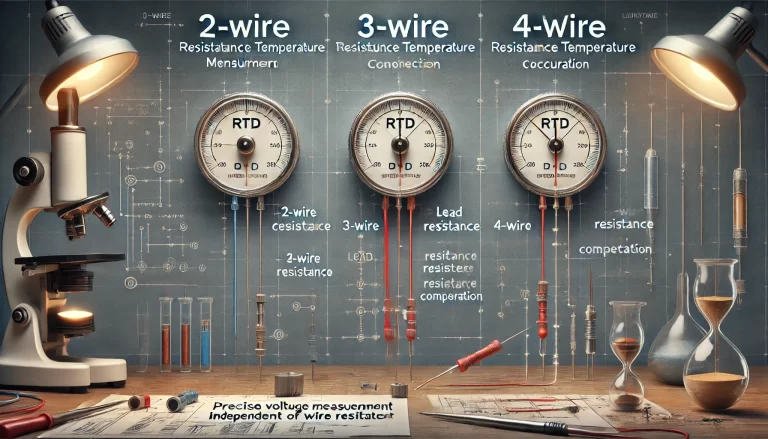

RTD temperature measurement involves different wiring configurations—2-wire, 3-wire, and 4-wire systems—each offering a trade-off between complexity, cost, and measurement accuracy. This article delves into the operational principles and applications of these configurations.

1. The 2-Wire RTD Configuration

Principle

In the 2-wire configuration, two wires connect the RTD to the measuring instrument. The resistance measured includes the resistance of the RTD element as well as the resistance of the connecting wires.

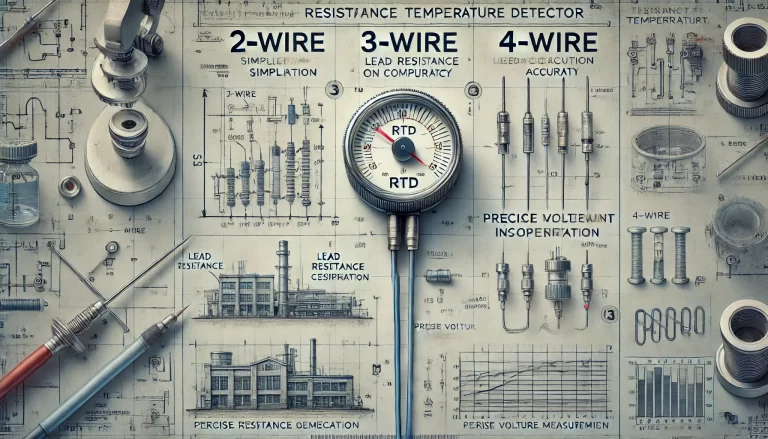

Advantages

- Simplicity: The 2-wire setup is straightforward, requiring minimal wiring.

- Cost-effectiveness: Fewer wires mean lower installation and material costs.

Disadvantages

- Inherent Error: The resistance of the connecting wires adds to the measured resistance, introducing error. This error is especially problematic for long cable runs or low-resistance RTDs like Pt100.

- Limited Accuracy: Since wire resistance varies with length, gauge, and temperature, it can significantly affect measurement precision.

Applications

The 2-wire configuration is suitable for:

- Short-distance measurements.

- Situations where high accuracy is not critical.

2. The 3-Wire RTD Configuration

Principle

The 3-wire configuration adds a third wire to compensate for the resistance of the connecting cables. The RTD element is connected to the instrument with three identical wires, and the instrument uses the third wire as a reference to calculate and subtract the lead resistance.

Advantages

- Improved Accuracy: By compensating for lead resistance, this configuration significantly reduces measurement errors.

- Cost-Effectiveness: Compared to the 4-wire configuration, the 3-wire setup is less expensive while offering adequate accuracy for many industrial applications.

Disadvantages

- Residual Error: The compensation assumes identical resistances in all three wires. Any mismatch in wire resistance introduces residual error.

Applications

The 3-wire configuration is commonly used in:

- Industrial environments.

- Medium-accuracy temperature measurement scenarios.

- Systems with moderate cable lengths.

3. The 4-Wire RTD Configuration

Principle

In the 4-wire configuration, two wires provide a constant current to the RTD, while the other two wires measure the voltage drop across the RTD. Since voltage measurement does not depend on the resistance of the connecting wires, this setup eliminates lead resistance effects entirely.

Advantages

- High Accuracy: The 4-wire system is the most precise configuration, as it completely compensates for lead resistance and is unaffected by wire length or gauge.

- Superior Stability: It is ideal for applications demanding consistent and repeatable measurements.

Disadvantages

- Complexity: The 4-wire setup requires more wiring and a more sophisticated measuring instrument.

- Higher Cost: Additional wires increase installation and material expenses.

Applications

The 4-wire configuration is used in:

- Laboratory environments requiring precise measurements.

- Critical industrial processes with stringent accuracy requirements.

- Long-distance signal transmission where lead resistance would otherwise be significant.

Comparison of Configurations

| Configuration | Wires Used | Accuracy | Cost | Applications |

|---|---|---|---|---|

| 2-Wire | 2 | Low | Lowest | Short-distance, low-precision needs. |

| 3-Wire | 3 | Medium | Moderate | Industrial systems with moderate accuracy needs. |

| 4-Wire | 4 | High (Best) | High | High-precision and long-distance measurements. |

Conclusion

The choice of RTD wiring configuration depends on the specific requirements of the application. A 2-wire system is ideal for simple, low-cost setups with minimal accuracy needs. A 3-wire system strikes a balance between cost and accuracy, making it the most popular choice in industrial settings. Meanwhile, a 4-wire system delivers unparalleled precision for demanding applications, albeit at a higher cost.

Understanding these configurations and their trade-offs helps ensure optimal performance in temperature measurement systems, whether for industrial control, scientific research, or other critical applications.