Control cables and shielded cables are both essential components in various electrical systems, but they serve distinct purposes and have unique structural differences. This article explains the detailed differences between these two types of cables, including their definitions, applications, structures, and features.

1. Definition and Purpose

Control Cables

Control cables are designed to transmit control signals to equipment or systems. Their primary purpose is to facilitate the operation, regulation, and monitoring of equipment in industrial or commercial environments. These cables are commonly used in automation systems, electrical instrumentation, and machine control applications. Control cables are engineered for signal transmission in environments where interference is not a critical concern.Shielded Cables

Shielded cables, on the other hand, are specifically designed to protect transmitted signals from electromagnetic interference (EMI) or to prevent the cable itself from emitting EMI. These cables are used to ensure reliable signal transmission in environments with high levels of electrical noise. They are widely applied in communication systems, audio and video equipment, and data transmission where signal integrity is crucial.

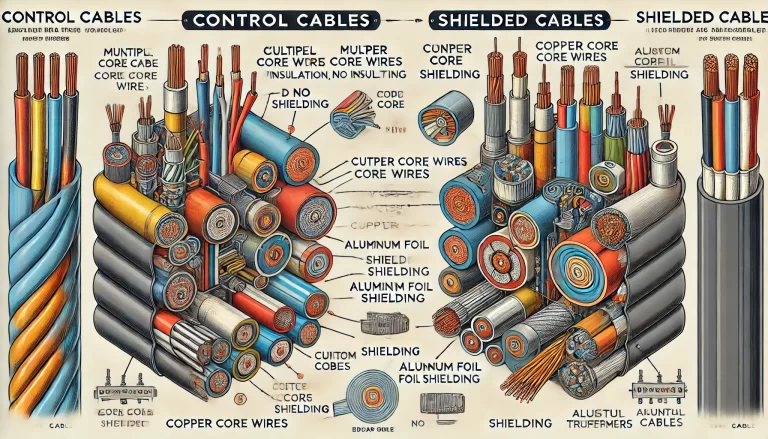

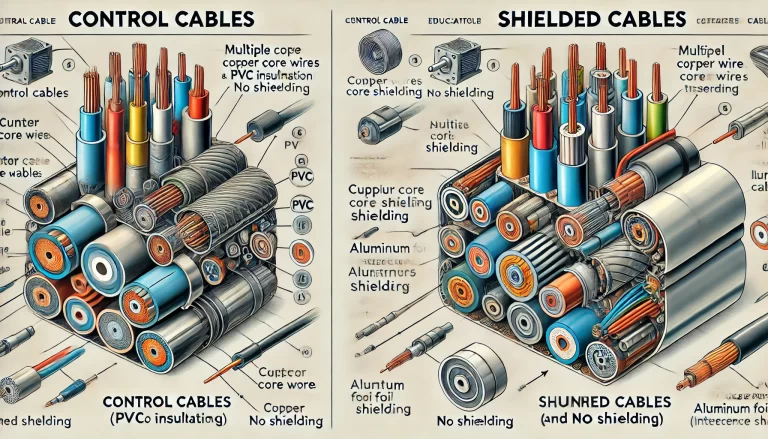

2. Structural Differences

Control Cables

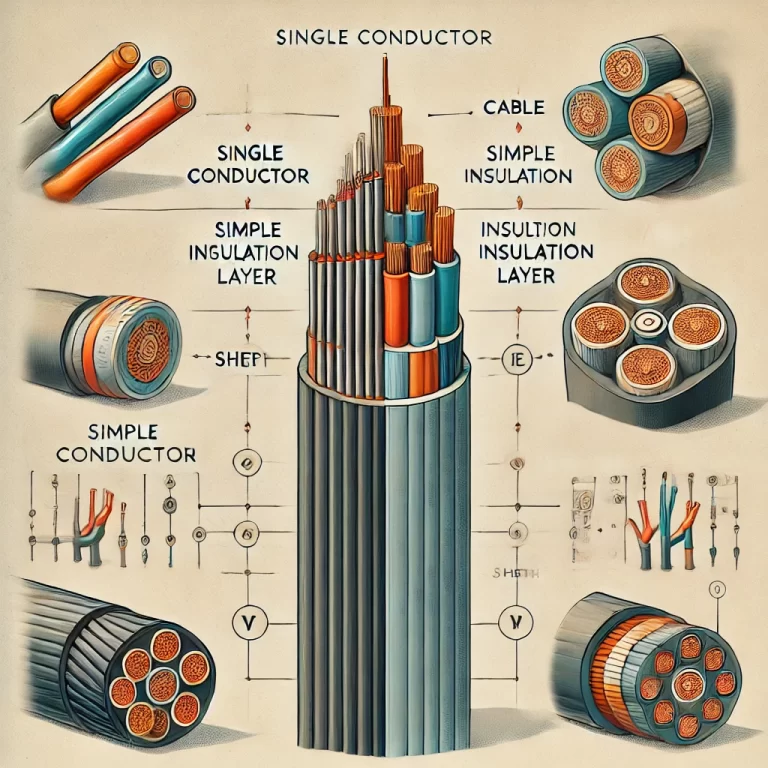

- Core Wires: Typically consist of multiple copper conductors to carry control signals.

- Insulation: Each conductor is insulated to prevent short circuits.

- Outer Sheath: A protective jacket, often made of PVC or other insulating materials, encases the conductors.

- Lack of Shielding: Control cables usually do not include shielding layers since they are intended for environments with minimal interference.

Shielded Cables

- Core Wires: Similar to control cables, shielded cables consist of multiple copper conductors.

- Shielding Layer: A crucial component, which can be made of materials like aluminum foil, copper braid, or a combination of both. The shielding layer blocks external interference and reduces noise.

- Insulation and Outer Sheath: These are similar to control cables, but the shielding layer adds an extra layer of protection, enhancing durability and performance in noisy environments.

3. Interference Resistance

Control Cables

- Designed for environments with minimal electromagnetic interference.

- Their primary focus is on signal transmission rather than noise prevention.

Shielded Cables

- Equipped with high resistance to EMI, making them suitable for environments with significant electrical noise or interference from nearby equipment like motors, transformers, or power lines.

4. Applications

Control Cables

- Industrial automation systems.

- Low-frequency signal transmission, such as equipment control circuits or power systems operating below 220V.

- Environments where electromagnetic interference is negligible.

Shielded Cables

- Communication systems (e.g., Ethernet cables, telephone lines).

- Audio and video signal transmission in studios, conference rooms, or broadcasting stations.

- Environments with significant electromagnetic noise, such as factories with heavy machinery, power plants, or high-frequency transmission lines.

5. Cost and Complexity

Control Cables

- Simpler structure and relatively lower cost.

- Ideal for basic signal transmission without the need for advanced interference protection.

Shielded Cables

- More complex construction due to the addition of shielding layers.

- Higher manufacturing costs make these cables more expensive than control cables.

6. Key Advantages

| Feature | Control Cables | Shielded Cables |

|---|---|---|

| Interference Resistance | Low | High |

| Signal Integrity | Sufficient for low-interference areas | Excellent, even in high-interference areas |

| Durability | Standard protection | Enhanced protection with shielding layers |

| Cost | Lower | Higher |

7. Choosing the Right Cable

The choice between control cables and shielded cables depends on the application and the environment:

When to Use Control Cables

- If the system is in a low-noise environment and requires simple signal transmission for control purposes.

- Suitable for basic automation, equipment control, or non-critical applications.

When to Use Shielded Cables

- In high-interference environments where signal integrity is critical.

- Ideal for sensitive data transmission, audio-visual systems, and communication networks.

Conclusion

Control cables and shielded cables serve different roles in electrical and electronic systems. Control cables are practical and cost-effective for transmitting signals in low-noise environments. Shielded cables, with their added EMI protection, are essential in settings where external interference could compromise signal quality. Understanding these differences ensures the appropriate selection of cables, optimizing system performance and reliability.