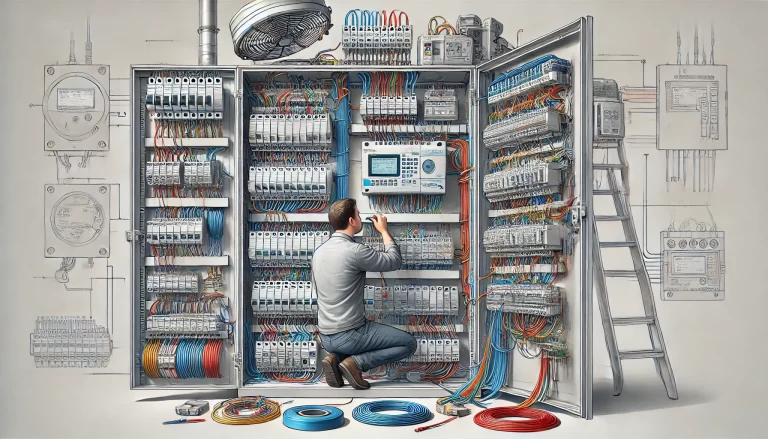

Programmable Logic Controllers (PLCs) are integral to industrial automation, allowing for precise control of machinery and processes. However, PLC outputs often require relays or similar devices to function effectively in real-world applications. This article explores the detailed reasons why relays are frequently added to PLC output terminals.

1. Electrical Isolation

One of the primary reasons to use a relay is to provide electrical isolation between the PLC and the external devices it controls. The PLC’s internal circuits typically operate at low voltages (e.g., 5V or 24V DC), whereas external devices may operate at much higher voltages (e.g., 110V or 220V AC).

Without isolation, a fault in the external device, such as a short circuit or voltage spike, could propagate back to the PLC, causing catastrophic damage. A relay acts as a barrier, ensuring that any electrical fault remains confined to the external circuit and does not affect the PLC.

2. Enhancing Load Driving Capability

PLCs often have limited output power, designed to handle only low-current signals. For example, a PLC output might be rated for a maximum current of 0.5A. Many industrial devices, such as motors, solenoid valves, and heating elements, require much higher currents to operate.

By using a relay, the PLC only needs to provide a small amount of current to energize the relay coil. Once activated, the relay’s contacts handle the higher current needed by the external device. This allows the PLC to control high-power loads indirectly.

3. Compatibility with Different Voltage Levels

The voltage levels of PLC outputs may not match the requirements of external devices. For instance, the PLC might output a 24V DC signal, while the external device requires 110V or 220V AC. Relays provide a simple and effective way to bridge this gap.

When the relay coil is energized by the PLC’s output, the relay contacts switch the higher voltage to the external device, ensuring compatibility without requiring additional circuitry.

4. Protection Against Inductive Loads

Many industrial devices, such as motors, solenoids, and contactors, are inductive loads. When the current to an inductive load is interrupted, the collapsing magnetic field generates a high-voltage spike (known as back EMF). This spike can damage sensitive PLC output circuits.

Relays are better suited to handle these spikes. For additional protection, a flyback diode or snubber circuit can be added across the relay coil to suppress voltage spikes.

5. Increased System Flexibility

Relays add flexibility to the control system. With a relay, you can:

- Switch multiple devices with different voltage and current requirements using the same PLC output.

- Use Normally Open (NO) or Normally Closed (NC) relay contacts to create customized control logic.

- Easily replace a relay to adapt the system to different load specifications without altering the PLC itself.

For instance, a single relay could switch both a low-voltage DC circuit and a high-voltage AC circuit using separate contacts, enabling more complex control scenarios.

6. Longevity of PLC Outputs

Directly connecting high-power loads to PLC outputs can shorten the lifespan of the output module. Even if the module can handle the load initially, repeated switching of high currents or voltages can wear out the output contacts or circuits over time.

Relays act as sacrificial components. If a relay fails, it is far cheaper and easier to replace than a PLC module. This not only protects the PLC but also reduces system downtime and maintenance costs.

7. Handling Special Control Requirements

Certain devices may require specific control characteristics, such as:

- High inrush currents: Some loads, like incandescent bulbs or capacitive devices, draw much higher currents at startup. Relays with high-current-rated contacts can accommodate this demand.

- Multi-point switching: A relay can control multiple circuits simultaneously, such as turning on a light and starting a fan with the same PLC output.

By incorporating relays, the PLC can manage these special cases effectively without additional circuitry.

Practical Example

Imagine a PLC controlling a 220V AC motor. The PLC’s output is a low-power, 24V DC signal. Without a relay, the PLC cannot directly drive the motor. By using a relay:

- The PLC energizes the relay coil with the 24V signal.

- The relay’s contacts close, completing the 220V AC circuit to power the motor.

- The motor starts safely without exposing the PLC to high voltages or currents.

Conclusion

Relays are an essential component in many PLC-controlled systems, serving as a bridge between the PLC and the real world. By adding relays to PLC outputs, you ensure:

- Electrical isolation for safety.

- Compatibility with higher voltages and currents.

- Protection of the PLC from electrical faults and wear.

- Increased system flexibility and reliability.

In industrial automation, the addition of relays to PLC outputs is a small investment that pays off in terms of safety, durability, and versatility. For engineers and technicians, understanding the role of relays is critical to designing robust and reliable control systems.