Turbine flow meters are widely used for their high accuracy, repeatability, and reliability in measuring fluid flow. Proper maintenance is crucial to ensure their long-term performance and reliability. This article outlines key steps and considerations for maintaining turbine flow meters.

1. Gradual Startup to Prevent Damage

When putting the flow meter into operation:

- Slowly open the upstream valve first, followed by the downstream valve.

- Avoid sudden surges of fluid that can damage the turbine due to high-impact forces.

- This gradual process prevents mechanical stress and extends the lifespan of the equipment.

2. Lubrication

- Follow the instructions on the operation notice for lubrication procedures.

- The frequency of lubrication depends on the cleanliness of the fluid. In general:

- For clean fluids, apply lubricant 2-3 times per year.

- For fluids with impurities, consider more frequent lubrication.

- Always use the lubricant type recommended by the manufacturer to prevent compatibility issues.

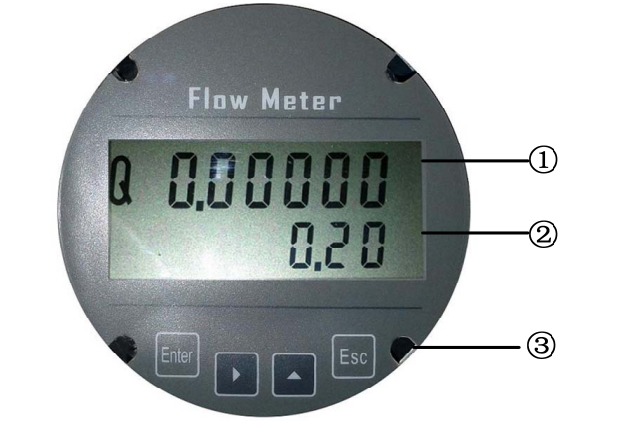

3. Avoid Unauthorized Adjustments

- During operation, do not open the front or rear covers of the flow meter.

- Avoid altering internal parameters unless authorized or guided by the manufacturer.

- Unauthorized adjustments can disrupt the flow meter’s calibration and functionality.

4. Dealing with Initial Issues

- If the flow meter encounters issues within the first six months of installation:

- Ensure that the problem is not caused by strong magnetic fields in the surrounding area.

- Verify the stability of the fluid flow; if unstable, install a flow straightener to rectify the issue.

5. Maintenance After Prolonged Use

- For meters in use for more than six months:

- Check for wear on bearings, especially if the fluid is impure or corrosive.

- Install a filter upstream to remove impurities and reduce wear on the turbine blades.

- Replace internal components like the impeller if necessary and recalibrate the flow meter.

- Note: The repeatability of turbine flow meters often diminishes after six months without proper care, so periodic recalibration is essential.

6. Ensuring Accurate Measurements

- Uneven flow distribution and secondary flow within the pipe are critical factors that affect accuracy. To address this:

- Ensure the installation includes straight pipe sections of sufficient length: 20 times the pipe diameter (20D) upstream and 5 times the pipe diameter (5D) downstream.

- Use a flow straightener to eliminate secondary flow and maintain a uniform velocity profile.

7. Handling Multiphase Flow

- To ensure single-phase fluid flow:

- Install a degasser upstream of the flow meter if gas bubbles are present in the fluid.

- For easily vaporized liquids, maintain a certain level of backpressure downstream.

- The required backpressure can be calculated as follows: Pback=2×Pflow sensor+1.2×Pvapor

- where Pflow sensor is the pressure of the flow sensor at maximum flow, and Pvapor is the vapor pressure of the liquid at the highest temperature

8. Additional Tips for Long-Term Reliability

- Periodically inspect the flow meter for physical damage or signs of corrosion.

- Maintain a clean environment around the flow meter to prevent debris from entering the system.

- Document all maintenance activities for reference during troubleshooting or future upgrades.

Visualizing Maintenance Steps

To simplify understanding, consider creating a flowchart or diagram illustrating the maintenance process. For example:

- Initial checks → 2. Gradual startup → 3. Lubrication → 4. Regular inspections → 5. Troubleshooting and recalibration.

Conclusion

Proper maintenance and care are essential to preserve the performance and accuracy of turbine flow meters. By following these steps, you can minimize downtime, extend the service life of the equipment, and ensure reliable flow measurements. Regular inspections, proper lubrication, and a focus on installation standards are key components of a comprehensive maintenance plan.

If you encounter persistent issues, consult the manufacturer’s guidelines or seek professional assistance.