Electrical cable entry is a critical aspect of explosion-proof equipment design and installation. It plays a pivotal role in maintaining safety in hazardous environments, such as those containing explosive gases, vapors, or dust. However, improper handling or oversight in this area can lead to severe risks. This article provides an in-depth explanation of common hazards associated with cable entry in explosion-proof equipment and how to address them effectively.

1. Poor Sealing

- Hazard: If the cable entry is not sealed properly, explosive gases or dust can enter the enclosure. In the presence of electrical sparks or high temperatures inside the equipment, this can result in an explosion.

- Causes:

- Use of substandard or inappropriate sealing materials.

- Inadequate tightening or improper installation of sealing glands.

- Preventive Measures:

- Use certified explosion-proof sealing glands and gaskets.

- Ensure that seals are properly compressed during installation.

- Conduct regular inspections to check for aging or deterioration of sealing materials and replace them when necessary.

2. Inadequate Cable Protection

- Hazard: Insufficient protection of cables can lead to mechanical damage, insulation failure, and subsequent risks such as short circuits or sparking.

- Causes:

- Absence of protective sheaths or conduits around the cable.

- Exposure of cables to physical impacts, sharp edges, or abrasive environments.

- Preventive Measures:

- Use armored or metal-sheathed cables where mechanical damage is a possibility.

- Route cables through protective conduits, cable trays, or ducts in areas prone to damage.

- Avoid routing cables through high-traffic or high-risk zones.

3. Unreliable Grounding

- Hazard: Inadequate grounding can result in the buildup of static electricity or make the equipment enclosure electrically live, increasing the risk of electric arcs or sparks that can ignite an explosion.

- Causes:

- Improper or loose grounding connections.

- Failure to install grounding components at the cable entry point.

- Preventive Measures:

- Ensure proper grounding of both the cable armor (if applicable) and the equipment enclosure.

- Periodically test the grounding system to confirm that resistance values remain within specified limits.

- Use grounding clamps and cables certified for use in explosion-proof installations.

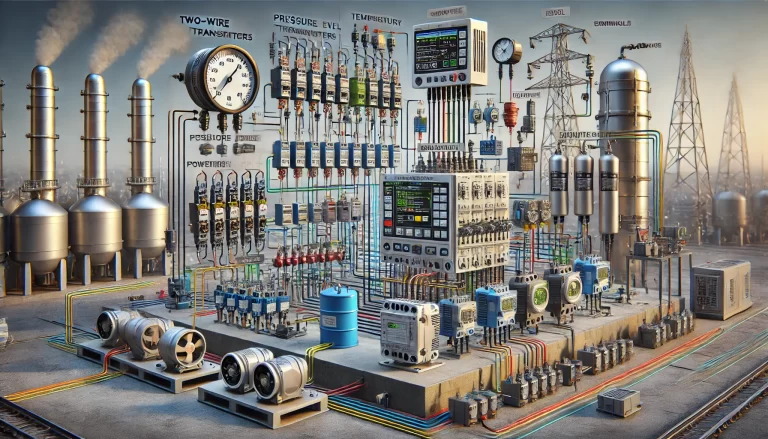

4. Use of Non-Compliant Components

- Hazard: Using non-certified or incompatible cable glands, connectors, or junction boxes can compromise the explosion-proof integrity of the equipment.

- Causes:

- Cost-cutting measures leading to the use of ordinary (non-explosion-proof) components.

- Lack of awareness of explosion-proof standards.

- Preventive Measures:

- Only use components with appropriate explosion-proof certifications (e.g., ATEX, IECEx, UL).

- Verify compatibility of components during design and procurement stages.

- Conduct thorough inspections before commissioning.

5. Overheating of Cables

- Hazard: Excessive heating of cables due to overloading or poor heat dissipation can degrade insulation, increase fire risks, or lead to explosions.

- Causes:

- Incorrect cable sizing with insufficient cross-sectional area for the load.

- Continuous operation near or beyond rated current capacity.

- Preventive Measures:

- Size cables correctly based on the load current and ambient temperature conditions.

- Use temperature-resistant cables if the equipment operates in a high-temperature environment.

- Regularly monitor the operating temperature of cables using thermal imaging tools.

6. Improper Cable Routing

- Hazard: Incorrect routing of cables can expose them to environmental factors such as high temperatures, corrosive substances, or moisture, reducing their lifespan and potentially causing failures.

- Causes:

- Routing through areas not designed for cable installation.

- Lack of consideration for environmental factors during installation.

- Preventive Measures:

- Plan cable routes to avoid proximity to heat sources, corrosive chemicals, or areas prone to water ingress.

- Use cables with specific resistance properties for challenging environments, such as corrosion-resistant or waterproof cables.

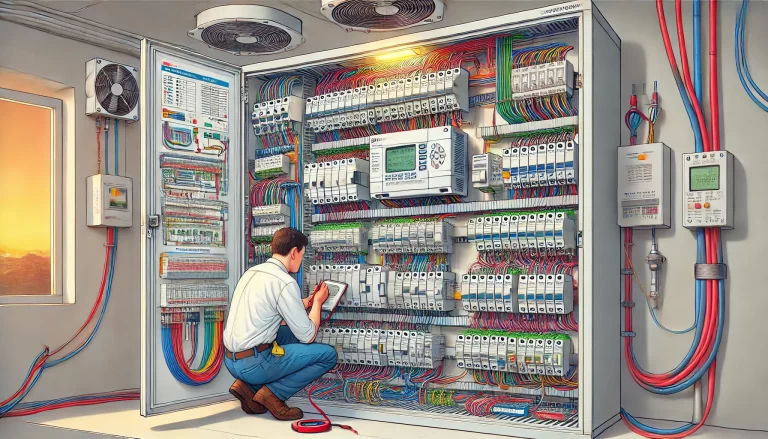

7. Insufficient Maintenance and Inspection

- Hazard: Lack of regular inspection and maintenance can lead to unnoticed degradation of cable entry seals, connections, or protective components.

- Causes:

- Neglect or insufficient knowledge among maintenance personnel.

- Failure to follow inspection schedules.

- Preventive Measures:

- Establish a routine maintenance schedule for explosion-proof equipment.

- Train personnel in the principles of explosion protection and proper handling of cable entry components.

- Perform periodic integrity tests on cable glands, seals, and other components to ensure continued compliance with safety standards.

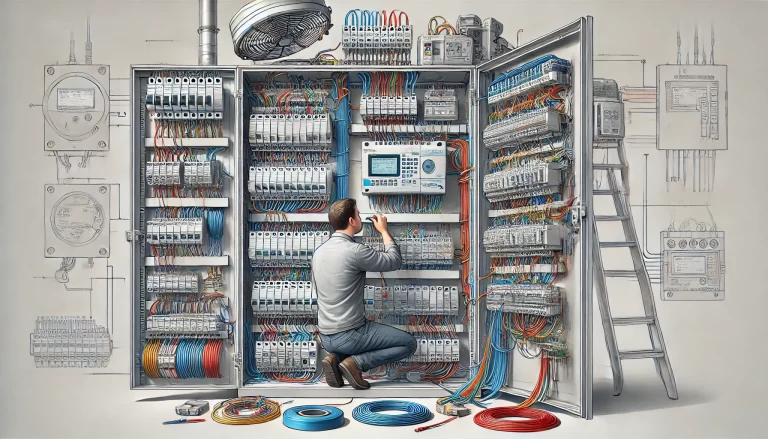

8. Improper Installation Practices

- Hazard: Poor installation practices can compromise the safety of cable entries, creating potential pathways for explosive substances to enter the enclosure or increasing the risk of cable failure.

- Causes:

- Lack of expertise among installation personnel.

- Failure to follow manufacturer instructions or explosion-proof installation guidelines.

- Preventive Measures:

- Ensure that installation is carried out by qualified and trained personnel.

- Adhere strictly to manufacturer-provided installation procedures and guidelines.

- Conduct post-installation inspections to verify compliance with explosion-proof standards.

Conclusion

The integrity of electrical cable entry points in explosion-proof equipment is critical for preventing accidents in hazardous environments. By addressing the potential hazards listed above and implementing robust preventive measures, companies can enhance the safety and reliability of their installations. Regular training, adherence to standards, and diligent maintenance are key to mitigating risks and ensuring long-term operational safety.