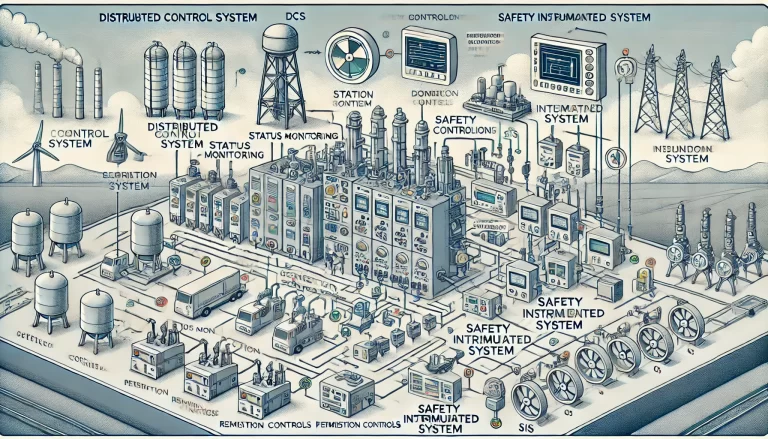

In industrial automation, ensuring continuous and reliable operation is crucial. Distributed Control Systems (DCS) play a vital role in process industries like oil and gas, power generation, and chemical production, where maintaining control stability is essential. DCS redundancy technology is a key factor in enhancing system reliability and mitigating the risk of operational interruptions caused by hardware or network failures. This article provides a detailed overview of DCS redundancy technology, its key components, and how it safeguards critical industrial processes.

What is DCS Redundancy Technology?

DCS redundancy technology involves implementing multiple layers of backup across various components within a Distributed Control System. By incorporating redundant elements at every critical point of the system, DCS redundancy ensures that any single point of failure doesn’t lead to a complete system shutdown. In essence, it provides a fault-tolerant architecture that allows uninterrupted control and monitoring even if specific parts of the system experience malfunctions.

Key Aspects of DCS Redundancy Technology

DCS redundancy can be categorized into several critical areas, each designed to handle different types of failures within the system:

1. Controller Redundancy

Controller redundancy is the most fundamental aspect of DCS redundancy. Controllers are the core processing units responsible for executing control algorithms and managing the flow of data within the DCS. In a redundant DCS setup, two (or more) controllers are configured in a primary and backup arrangement.

- Primary Controller: This controller handles real-time data processing and system control tasks under normal conditions.

- Backup Controller: The backup controller remains in standby mode and continuously monitors the primary controller’s operation. If the primary controller fails, the backup controller takes over immediately, minimizing any disruption in control functions.

Redundant controllers usually have synchronized data to allow seamless switching, a critical feature in high-stakes environments such as oil refineries, where even a slight delay in switching can lead to production issues or safety hazards.

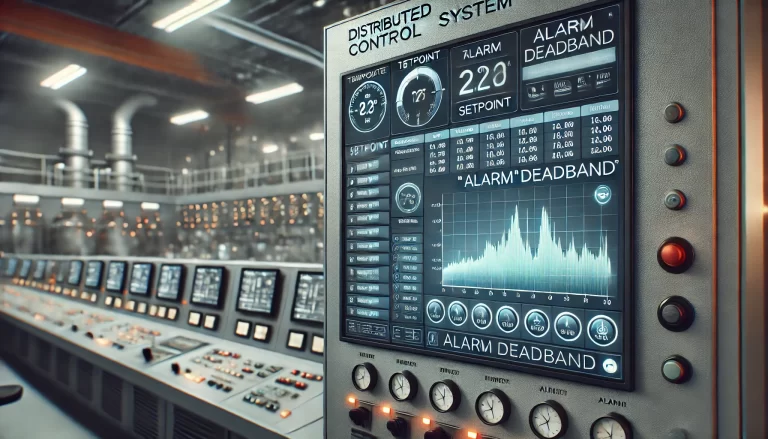

2. Network Redundancy

In a DCS, network redundancy is essential for reliable data transmission. DCS networks are used to facilitate communication between controllers, field devices, and operator workstations. Network redundancy is commonly achieved through two methods:

- Dual Network Configuration: This involves two identical, independent network paths, usually using Ethernet connections. If one network path fails, communication automatically switches to the other, ensuring continuous data flow.

- Ring Topology: A ring network configuration provides multiple communication paths between nodes. This topology allows for automatic rerouting of data if a network link fails, further enhancing network resilience.

By ensuring network redundancy, DCS systems can avoid interruptions due to network failures, thereby maintaining data integrity and real-time monitoring capabilities.

3. Power Redundancy

Reliable power supply is crucial for any automation system. In DCS systems, power redundancy is typically implemented with dual power supplies:

- Dual Power Supply: Key devices, such as controllers and network equipment, are supplied by two independent power sources. If one power supply fails, the other immediately takes over, ensuring there is no power loss to critical components.

- Uninterruptible Power Supply (UPS): In some cases, a UPS is added as a backup to handle any momentary lapses in power or during transitions between primary and secondary power supplies.

Power redundancy enhances the reliability of DCS systems by protecting against power-related failures that could otherwise disrupt the entire control process.

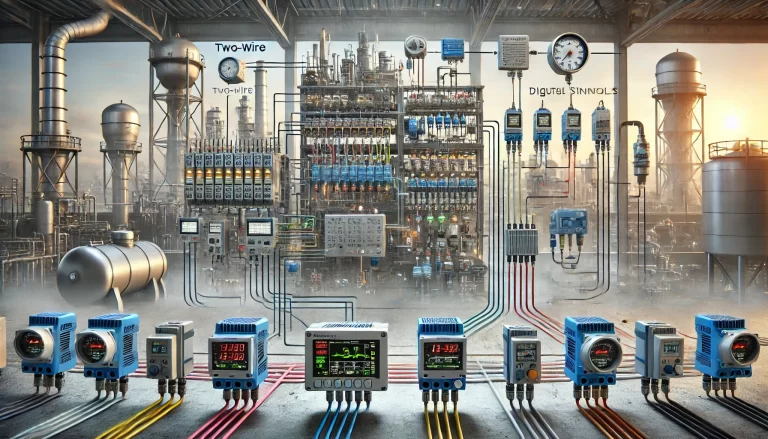

4. I/O Module Redundancy

Input/Output (I/O) modules play a crucial role in DCS systems as they interface with field devices, collecting real-time data and sending control signals. I/O redundancy involves duplicating these modules to ensure data availability and control functionality:

- Redundant I/O Modules: With redundant I/O, two sets of I/O modules are used. One set actively communicates with field devices while the other set is on standby. In the event of a failure in the primary I/O module, the standby module takes over seamlessly.

- Hot Swappable I/O: In advanced DCS designs, I/O modules are hot-swappable, allowing operators to replace failed modules without interrupting system operations.

By using redundant I/O modules, DCS systems can maintain data continuity even when individual modules fail, thus preserving the integrity of control and monitoring processes.

5. Communication Redundancy

DCS communication modules and protocols are also designed with redundancy to ensure reliable data transmission between system components. This includes redundancy at both the communication hardware and software protocol levels:

- Communication Protocols: Protocols such as Modbus TCP/IP and Profinet allow for redundant paths in data exchange. This ensures that communication is not lost even if one pathway experiences an issue.

- Redundant Communication Hardware: DCS systems often employ duplicate communication hardware (e.g., routers, switches) that automatically switch in the event of a failure, maintaining uninterrupted data flow.

Communication redundancy is especially important in large-scale industrial setups with a high volume of data exchange between sensors, controllers, and operators.

Benefits of DCS Redundancy Technology

Implementing redundancy in DCS systems offers multiple benefits, including:

- Increased Reliability: Redundant components enable continuous system operation even during hardware or network failures, ensuring process reliability and reducing downtime.

- Improved Safety: Redundant designs allow quick switching to backup systems, essential for maintaining control in hazardous environments and preventing safety incidents.

- Enhanced Data Integrity: Redundant I/O and communication modules ensure that all data is accurately collected and transmitted, reducing the risk of data loss or corruption.

- Cost Savings: While redundancy initially increases installation costs, the reduction in unplanned downtime and maintenance needs leads to long-term cost savings, making redundancy a valuable investment.

Conclusion

DCS redundancy technology is a critical component of industrial automation, particularly for industries requiring high uptime and reliability. By implementing controller, network, power, I/O, and communication redundancies, DCS systems become robust, fault-tolerant solutions capable of handling unexpected failures without disrupting processes. This technology enables operators to maintain control and monitor essential systems even in challenging conditions, safeguarding both productivity and safety in industrial environments.