Introduction

In the pulse of industrial production, dust explosion prevention stands as an essential barrier, safeguarding every frontline worker’s life and the company’s assets. With the increase in dust-processing industries, the risk of dust explosions has also escalated. This article delves into the critical importance of dust explosion prevention, highlights recent incidents, and outlines effective safety measures.

The Hazards of Dust Explosions

Dust explosions pose severe threats, causing potential loss of life, devastating financial damage, and disrupting operational continuity. Imagine a dust-laden factory floor suddenly erupting with a fiery explosion—a horrifying scenario. Recent data reveal that industries like metal processing, woodwork, and grain handling are especially vulnerable, where airborne dust particles can ignite within seconds, causing destruction across wide areas.

Conditions Leading to Dust Explosions

A dust explosion requires five key elements, often referred to as the “Dust Explosion Pentagon”:

- Combustible Dust: Any dust that can oxidize and burn in the presence of an oxidizing agent, such as aluminum, coal, or sugar dust.

- Dust Cloud: Suspended combustible dust particles in the air within the explosive concentration range.

- Ignition Source: A spark, flame, or hot surface with enough energy to ignite the dust cloud.

- Oxidant: Typically, oxygen in the air acts as the oxidizer that fuels the reaction.

- Confined Space: An enclosed or semi-enclosed space where a dust cloud ignition leads to rapid pressure buildup, causing an explosion.

When these conditions coexist, an otherwise benign workspace can become an explosive hazard.

Effective Measures for Dust Explosion Prevention

To effectively mitigate the risk of dust explosions, industries should adopt a multi-tiered approach that includes equipment safeguards, regular monitoring, and strong organizational controls.

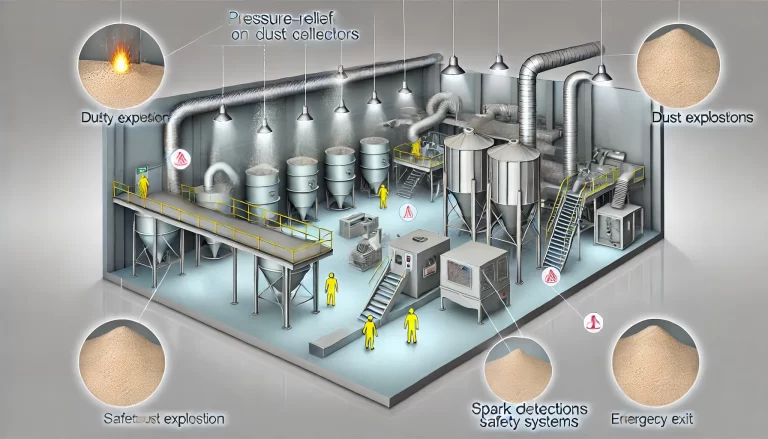

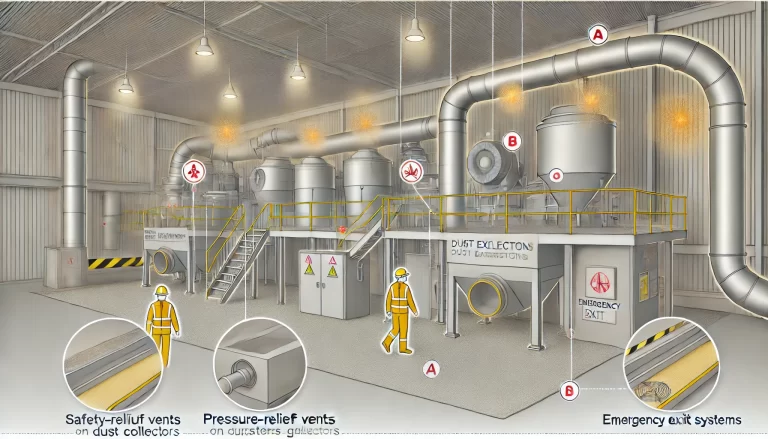

1. Explosion-Proofing Dust Collectors

- Explosion Venting: Dust collectors should have pressure-relief vents, such as explosion vents and rupture disks, designed to release pressure in case of an explosion. This reduces the risk of catastrophic equipment damage.

- Isolation: Equip dust collection systems with isolation devices like explosion isolation valves to prevent the spread of explosions to other parts of the facility.

- Suppression: Explosion suppression systems detect an explosion early and discharge suppressants, effectively limiting or stopping the explosion spread.

2. Differential Pressure and Spark Detection

- Differential Pressure Alarm: Monitoring the pressure difference across filter bags in dust collectors helps prevent filter blockage. An alarm system alerts when maintenance is needed, reducing fire and explosion risks.

- Spark Detection and Extinguishing Systems: Spark detectors in ductwork or silos detect sparks or embers in the airflow. The system then triggers high-pressure nozzles that extinguish the spark before it reaches a combustible environment.

3. Comprehensive Dust Explosion Safety Management

To ensure safe operations, organizations should establish robust safety protocols, emphasizing risk assessment, operational standards, training, and emergency response.

- Risk Identification and Control: Conduct regular assessments to identify high-risk areas, evaluate explosion likelihood, and implement control measures to mitigate those risks.

- Management System Improvements: Establish a clear chain of safety responsibility. Each role should understand its obligations toward maintaining a safe work environment.

- Regular Safety Inspections: Schedule periodic inspections to review and enhance safety protocols, considering changes in machinery, production volume, or dust levels.

- Training and Awareness Programs: Educate employees on dust explosion risks, relevant regulations, and operational safety practices. Training should emphasize proactive hazard recognition and compliance with safety standards.

- Emergency Preparedness: Develop, review, and conduct regular drills on emergency response plans to ensure quick and efficient response in the event of an explosion.

- Safety Warnings and Hazard Signage: Place clear warning signs around high-risk areas, especially where combustible dust and ignition sources are present.

- Hot Work Management: Hot work (e.g., welding, cutting) should be approved by management to ensure safety protocols are in place before proceeding.

4. Use of Certified Explosion-Proof Equipment

In explosion-prone environments, using certified explosion-proof instruments is crucial. For instance, dual-certified instruments (for gas and dust environments) provide reliable performance and reduce explosion risks. Always choose equipment that complies with national or international safety standards.

Case Example: Preventing Dust Explosions in a Flour Mill

A flour mill, inherently prone to dust explosions, provides a practical example. By implementing spark detection systems in ductwork, adding explosion vents on silos, and scheduling regular dust removal procedures, the mill reduced its risk. Staff undergo mandatory safety training quarterly, reinforcing awareness and readiness. This comprehensive approach has minimized incidents and improved workplace safety.

Conclusion

Dust explosion prevention is integral to industrial safety. By implementing measures such as dust collector explosion-proofing, regular maintenance, and thorough safety management protocols, industries can effectively reduce the risk of explosions, protecting employees and assets. Each facility must tailor its explosion prevention strategies to its specific needs, ensuring that safety protocols evolve alongside operational demands. Investing in employee training and certified equipment further strengthens this safety culture, fostering an environment where risk is minimized and productivity thrives.