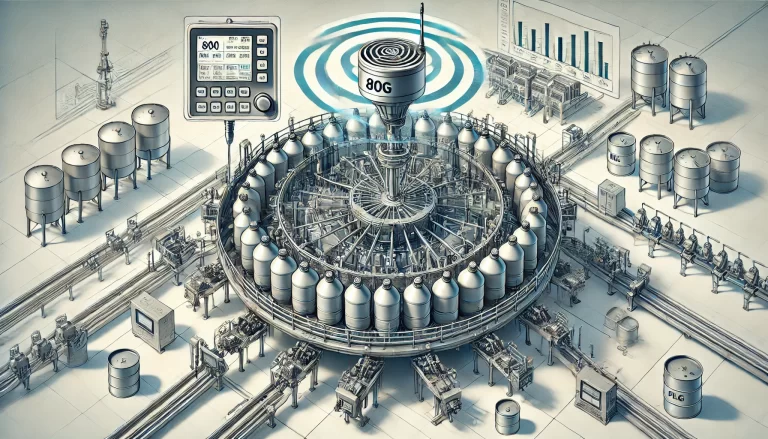

With the rapid development of industrial automation technology, rotary filling systems have emerged as a key technology to enhance production efficiency and product quality. These systems are widely applied in industries like food, pharmaceuticals, and cosmetics, where high-speed, continuous production is required. However, one of the major challenges in this field is accurately and consistently monitoring and managing material levels to ensure filling precision and efficiency during high-speed operation. This article explores the innovative application of the 80G radar level meter in rotary filling systems and highlights the advantages it brings to modern industry.

1. Importance of Material Level Control in Rotary Filling Systems

Rotary filling systems are known for their high efficiency and accuracy, making them indispensable in the packaging of liquids, semi-fluids, and some solids. These systems operate by rotating continuously, allowing simultaneous filling of multiple containers or bottles, which significantly boosts production throughput. However, accurate control of material levels is essential for such systems to operate reliably.

In rotary filling, if the material level is too high, it may cause overflow, leading to waste and potential contamination. Conversely, if the level is too low, it can impair filling accuracy or even cause interruptions. Therefore, real-time, precise monitoring of material levels is crucial to maintaining the stability and efficiency of these systems.

2. Advantages of 80G Radar Level Meter Technology

The 80G radar level meter is an advanced level measurement instrument that has proven its reliability in a variety of industrial applications. It uses Frequency Modulated Continuous Wave (FMCW) technology to transmit high-frequency electromagnetic waves and receive reflected signals, allowing precise calculation of material level. This technology offers several key advantages over traditional level measurement methods:

- High Precision: The 80G radar level meter can achieve measurement accuracy of up to ±1mm, which meets the strict requirements for level control in rotary filling systems.

- Non-Contact Measurement: By avoiding direct contact with materials, the radar level meter reduces the risk of contamination, making it particularly suitable for industries with strict hygiene standards, such as food and pharmaceuticals.

- Superior Penetration Capability: The high frequency of the 80GHz electromagnetic wave allows it to penetrate various media effectively, maintaining stable measurement performance even in challenging conditions, such as environments with steam, foam, or dust.

- Compact and Easy to Install: With a simple structure and compact design, the radar level meter can be installed easily, even in narrow spaces. Additionally, its non-contact measurement nature lowers maintenance needs and reduces operational costs.

3. Integration of 80G Radar Level Meters in Rotary Filling Systems

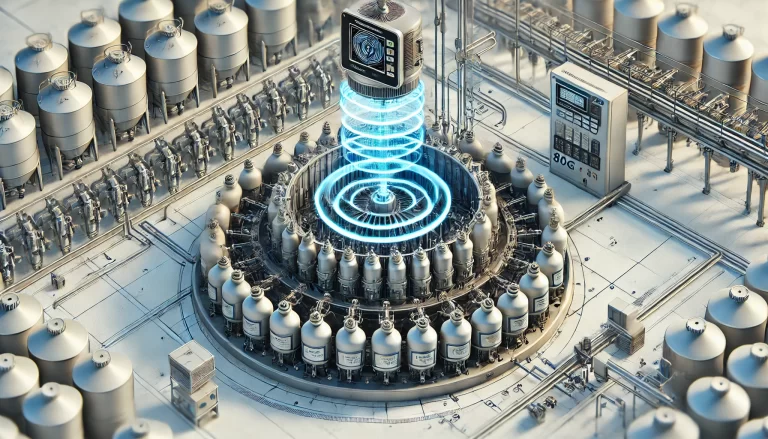

In rotary filling systems, the 80G radar level meter is strategically integrated at the top of filling pipelines or storage tanks, allowing it to provide real-time monitoring of material levels. This application is typically combined with a Programmable Logic Controller (PLC) to form a closed-loop control system that ensures seamless operation.

Here’s how the integrated system works:

- Real-Time Monitoring and Signal Transmission: When the material level reaches a pre-set threshold, the radar level meter sends an immediate signal to the PLC.

- Automated Adjustment: The PLC processes the signal and adjusts the filling speed or stops filling as needed to keep the material level within an optimal range.

- Closed-Loop Control: This closed-loop control approach enhances the filling precision and operational efficiency of the system, reducing material wastage and production costs.

The integration of the radar level meter with PLC control also offers a flexible and adaptive response to varying production requirements. For instance, the system can adjust the fill rate dynamically based on real-time level readings, adapting to changes in production demand or material properties.

4. Benefits of 80G Radar Level Meter in Industrial Applications

The use of 80G radar level meters in rotary filling systems addresses numerous challenges present in traditional level measurement approaches. With its exceptional precision, reliability in complex conditions, and low maintenance requirements, it provides several key benefits:

- Enhanced Precision and Efficiency: By achieving high measurement accuracy, the radar level meter ensures consistent filling precision, which is critical in applications where product quality is directly impacted by filling accuracy.

- Reduction in Material Wastage and Downtime: Real-time level monitoring helps avoid issues like overflow or underfill, which not only waste materials but can also lead to production stoppages and increased maintenance requirements.

- Adaptability to Harsh Environments: The radar level meter remains accurate in environments with factors like steam, foam, or dust, common in industries such as food processing and chemicals, making it a reliable solution for complex industrial applications.

- Cost Savings and Lower Maintenance Needs: The non-contact measurement nature and compact structure mean less wear and tear, reducing the need for frequent maintenance and lowering overall operational costs.

Conclusion

The innovative application of the 80G radar level meter in rotary filling systems has brought unprecedented efficiency and accuracy to industrial production processes. By addressing the limitations of traditional level measurement methods, this technology provides a highly reliable solution for maintaining optimal filling levels, reducing waste, and enhancing product quality. As industries continue to evolve and adopt more sophisticated automation technologies, the 80G radar level meter will undoubtedly play an increasingly vital role in driving efficiency and productivity.