Differential pressure (DP) transmitters are commonly used for flow measurement in various industrial applications. The principle is rooted in Bernoulli’s equation and the relationship between pressure differentials and flow rates in fluid dynamics. Here, we’ll explore the detailed workings of DP transmitters, the types of primary devices involved, and practical considerations for their use.

Principle Explanation

DP transmitters function by measuring the pressure difference created when a fluid passes through a specially designed constriction within a pipeline. This constriction can be in the form of an orifice plate, Venturi tube, or nozzle. According to Bernoulli’s principle, as fluid velocity increases through the constriction, the static pressure decreases, creating a measurable pressure differential. The DP transmitter senses this difference and outputs an electrical signal that can be used to calculate the flow rate.

Calculation Formula

The relationship between the measured pressure differential (∆P) and the volumetric flow rate (Q) can be described by the equation:

Where:

C is a flow coefficient that depends on the geometry of the constriction.

∆P is the pressure differential measured by the DP transmitter.

ρ is the density of the fluid.

This equation shows that the flow rate is proportional to the square root of the pressure differential.

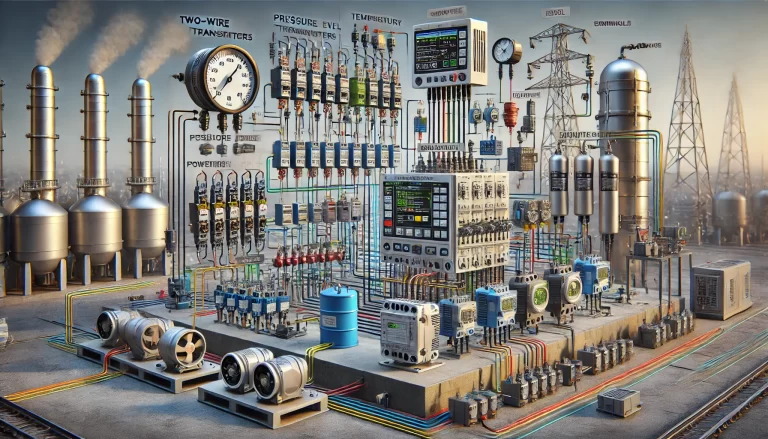

Required Hardware

For accurate flow measurement, DP transmitters are typically used with specific hardware that ensures reliable pressure differential creation and signal processing. These components include:

Primary Flow Devices (Constrictors):

Orifice Plate: A flat plate with a precisely machined hole that creates a pressure drop as fluid flows through it.

Advantages: Simple structure, low cost, suitable for most fluids.

Disadvantages: Higher pressure loss, potential accuracy degradation over time due to wear and fouling.

Applications: Commonly used in water, steam, and gas flow measurement.

Venturi Tube: A constriction device with a tapered shape that minimizes energy loss.

Advantages: Lower pressure drop, high measurement accuracy.

Disadvantages: Higher initial cost, larger installation space required.

Applications: Ideal for large pipelines in water treatment facilities, steam systems, and liquid transportation.

Nozzle: Designed for high-velocity fluid measurement, featuring a tapered entrance that reduces turbulence.

Advantages: Lower pressure loss compared to orifice plates, durable.

Disadvantages: More complex structure, slightly higher cost.

Applications: Used in steam boilers, high-pressure gas pipelines, and industrial applications with high flow rates.

2. Flow Computing Devices:

Flow Totalizer or PLC: These devices interpret the electrical signal from the DP transmitter and convert it into a flow rate for monitoring and control purposes.

3. Piping and Accessories:

Pipes and Fittings: Essential for securely installing the primary device and transmitter to ensure stable pressure differential readings.

Detailed Description of Primary Devices

1. Orifice Plate (Orifice Plate)

An orifice plate is the simplest form of flow constriction device. It consists of a thin metal plate with a central hole, installed perpendicular to the flow. As the fluid passes through the hole, the flow speed increases, causing a drop in static pressure.

Working Principle: The sudden decrease in cross-sectional area leads to a rapid increase in flow speed, generating a measurable pressure difference.

Advantages:

Cost-effective and easy to install.

Widely applicable for liquids and gases.

Disadvantages:

High permanent pressure loss.

Susceptible to accuracy degradation due to wear or debris accumulation.

Typical Uses: Employed in industries such as oil, gas, and chemical processing for water, air, and steam flow measurement.

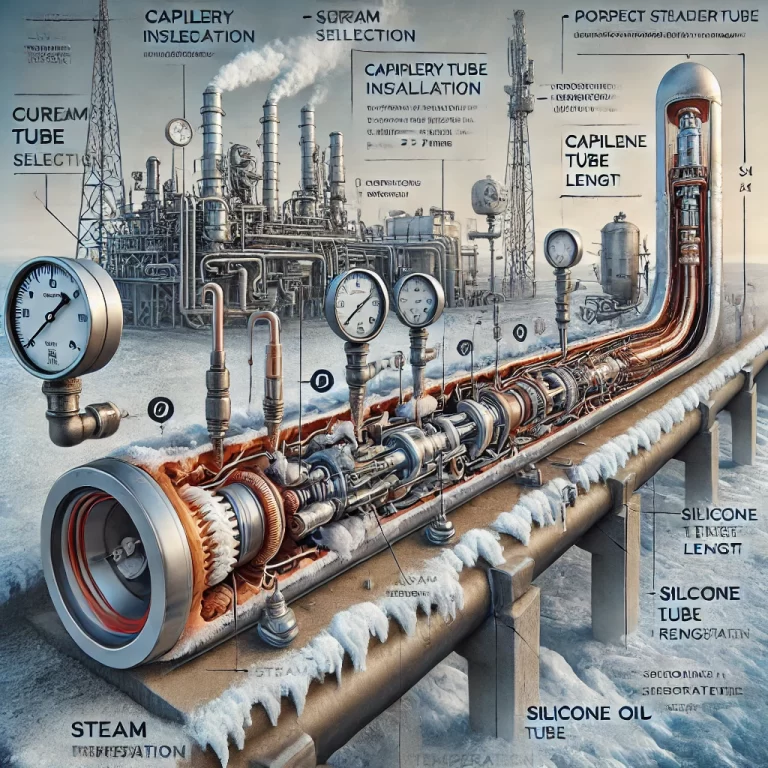

2. Venturi Tube

The Venturi tube is a more advanced and efficient primary device designed to minimize energy loss.

Working Principle: Fluid entering the narrowed throat of the Venturi tube accelerates, causing a pressure drop. Upon exiting into the expansion section, partial pressure recovery occurs.

Advantages:

Minimal permanent pressure loss.

High accuracy, ideal for high-demand applications.

Disadvantages:

More expensive and requires more installation space compared to orifice plates.

Typical Uses: Used in municipal water supply systems, industrial liquid transfer, and steam flow monitoring.

3. Nozzle

Flow nozzles are designed for scenarios requiring the measurement of high-speed fluids.

Working Principle: The nozzle shape gradually narrows, accelerating the fluid and generating a pressure drop with reduced turbulence.

Advantages:

Lower permanent pressure loss compared to orifice plates.

High durability and stability for long-term use.

Disadvantages:

More complex design and slightly higher cost.

Typical Uses: Applied in the measurement of high-temperature steam and high-pressure gas.

Special Considerations

When choosing a primary device for differential pressure measurement, consider:

Fluid Characteristics: Different devices are optimized for various fluids (e.g., liquids, gases, or steam).

Measurement Accuracy: For precise measurement, Venturi tubes and nozzles are preferable.

Pressure Loss Requirements: If low pressure loss is critical, Venturi tubes or balanced flow meters are recommended.

Cost and Maintenance: While orifice plates are budget-friendly, they may require more frequent maintenance. Venturi tubes and nozzles, though costlier, offer lower maintenance needs and better long-term accuracy.

Practical Applications

Power Plant Steam Measurement: Flow nozzles or Venturi tubes are used due to their high-pressure and high-temperature resilience.

Natural Gas Pipelines: Orifice plates are commonly chosen for their simplicity and cost-effectiveness.

Wastewater Treatment: Balanced flow meters can be utilized to mitigate clogging and ensure stable measurements in challenging conditions.

By understanding the detailed workings, advantages, and applications of differential pressure transmitters and their associated primary devices, industries can make informed decisions for optimal flow measurement and process efficiency.