Recently, during my service visit to a refining and chemical enterprise in Shandong, I had the opportunity to examine multiple systems where PID tuning had been previously conducted by various companies. It is evident that the industry has made significant advancements in PID tuning practices. However, there remains a considerable gap in the capability to solve complex problems effectively through parameter tuning and comprehensive solution design. Each system I observed had not yet fully leveraged its equipment’s potential performance.

The root causes of these issues extend beyond the engineers’ technical proficiency in implementing automation enhancements. A significant factor lies in how enterprises prioritize certain metrics during PID tuning projects, notably focusing on self-control rate and stability rate. The contract specifications often outline these metrics, reflecting the core objectives of the enterprise. Yet, as seen in the project execution, some notable challenges persist.

Challenges in Project Execution

1. Performance Metrics and Engineer Behavior: When compensation is based on the number of loops tuned or similar quantifiable metrics, engineers are incentivized to choose tasks that are simpler and more resource-efficient. Complex and critical problems, which require extensive resources and higher cognitive effort, are frequently overlooked or deprioritized. This creates an imbalance where simpler tasks receive more attention than the more pressing, intricate challenges that can substantially enhance system performance.

2. Workflow and Error Correction: Any correction to flawed plans requires structured processes and reconfiguration of system setups. Completing these tasks within the project timeframe demands meticulous planning. If a project encounters errors that necessitate adjustments, the time and effort needed to implement these changes can be considerable. Without efficient processes in place, error correction becomes burdensome, leading to potential project delays or suboptimal outcomes.

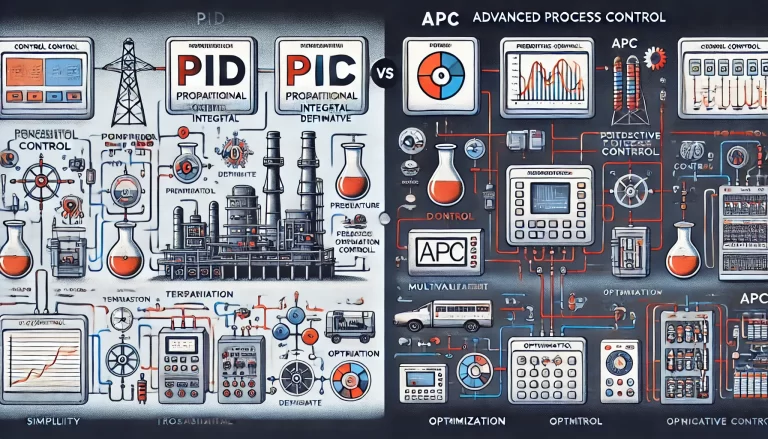

3. Implementation of New Solutions: Introducing new solutions often requires expertise beyond the scope of typical PID loop adjustments. These advanced solutions, which might involve designing and implementing control strategies beyond standard feedback loops, are not typically included in performance assessments. Unless specifically requested by the process engineering team, these enhancements are seldom executed. This reluctance stems from the added complexity and the absence of direct compensation for efforts outside the project’s contractual bounds.

Limitations of Current Industry Practices

The industry’s prevailing focus on self-control rate and stability rate, along with billing models based on the number of tuned control loops, highlights systemic limitations. These metrics, while important, do not capture the holistic performance improvements achievable through comprehensive process optimization. Solving intricate issues requires significantly greater resources and a higher level of engineering expertise compared to standard PID tuning. The investment in solving these complex problems is often many times that of simple loop adjustments.

The ultimate objective of automation is to reduce the need for human intervention and enhance operational safety and efficiency. A project should be assessed not only on achieving high self-control and stability rates but on its ability to minimize operational events and process alarms. Automation projects should focus on reducing the frequency of operator interventions, aiming for a state of zero manual operations and zero sustained oscillations.

A Vision for Improved Automation Practices

An effective automation improvement project should prioritize reducing operational events within the control system and minimizing process alarms. If a project can reduce manual operations by 50%, it should be considered a success. From that foundation, continuous improvement efforts, including iterative decision-making and implementation cycles, can help gradually achieve even more ambitious targets.

In conclusion, while the emphasis on self-control rate and stability rate is well-meaning, it must evolve. The industry should adopt a more nuanced approach that considers the overall effectiveness of automation projects. Engineers must be empowered and incentivized to tackle complex issues, supported by processes that facilitate adaptation and innovation. This shift will ensure that automation fulfills its true purpose: reducing human workload and optimizing system performance for greater safety and efficiency.