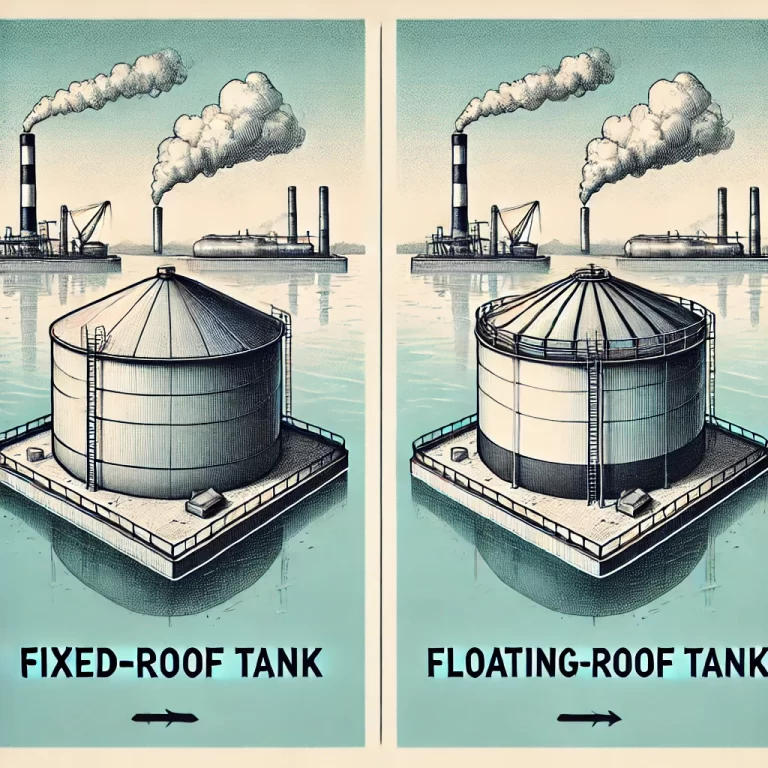

When it comes to industrial liquid storage solutions, selecting the appropriate type of tank is crucial for efficiency, safety, and cost management. Fixed-roof tanks and floating-roof tanks are two of the most commonly used storage options. Understanding their distinct characteristics, advantages, and limitations can help industries make informed decisions tailored to their specific needs. This article provides an in-depth analysis of these two types of storage tanks.

1. Overview of Fixed-Roof Tanks

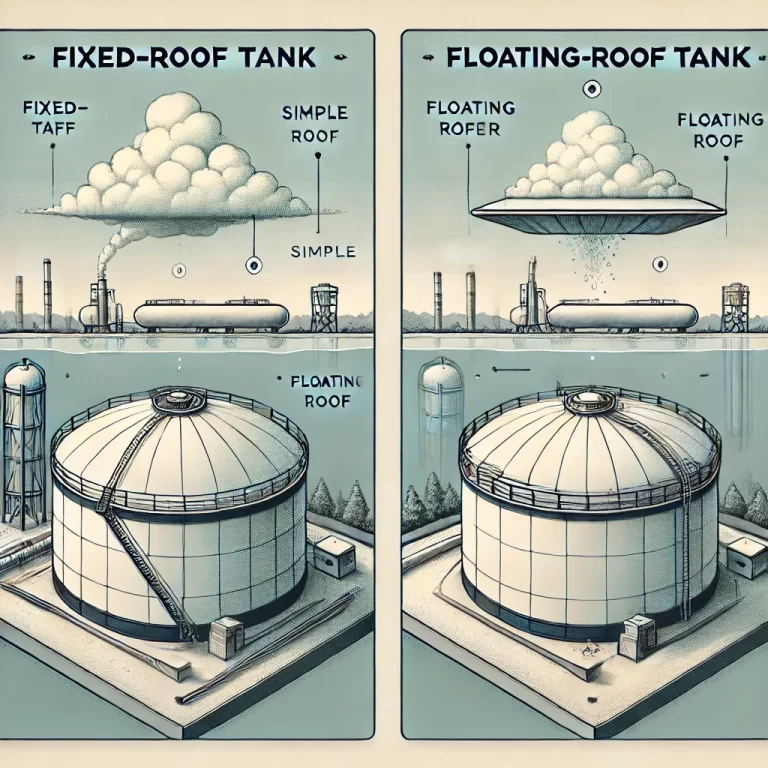

Fixed-roof tanks are designed with a permanently affixed roof that covers the entire structure. The roof may be dome-shaped, cone-shaped, or flat, depending on the specific design and purpose of the tank. These tanks are commonly used for storing a variety of liquid products, including water, chemicals, and low-volatility hydrocarbons.

Advantages of Fixed-Roof Tanks

Simplicity of Structure: Fixed-roof tanks are simpler in construction compared to floating-roof tanks. This structural simplicity translates to lower initial construction and maintenance costs.

Versatile Application: They are adaptable to a broad range of liquid products, making them suitable for diverse storage needs.

Protection from External Elements: The roof provides effective protection against environmental factors such as rain, wind, and dust, which is beneficial for maintaining product integrity.

Disadvantages of Fixed-Roof Tanks

High Evaporation Losses: One of the significant drawbacks of fixed-roof tanks is the potential for higher evaporation losses, especially when storing volatile liquids. The vapor space above the liquid allows for significant vapor accumulation, which can lead to product loss.

Increased Risk of Vapor Buildup: The accumulation of vapors poses a safety risk, as these gases can potentially ignite and cause fires or explosions. This necessitates the installation of additional safety measures such as pressure relief valves and venting systems.

Environmental Concerns: The release of evaporated gases into the atmosphere can contribute to air pollution and greenhouse gas emissions.

2. Overview of Floating-Roof Tanks

Floating-roof tanks are equipped with a roof that floats directly on the surface of the stored liquid, rising or falling in accordance with the liquid level. This type of tank is primarily used for storing highly volatile liquids such as crude oil, gasoline, and other petroleum products.

Advantages of Floating-Roof Tanks

Reduced Evaporation Losses: The design of floating-roof tanks minimizes the amount of vapor space above the liquid, significantly reducing evaporation losses. This feature is especially beneficial for storing products that are prone to vaporization.

Enhanced Safety: By limiting the buildup of vapor, floating-roof tanks help to mitigate the risk of flammable gas accumulation. This reduces the likelihood of fires or explosions.

Long-Term Cost Savings: Although floating-roof tanks have higher initial construction costs, the reduction in product losses due to minimized evaporation can result in significant long-term cost savings

Disadvantages of Floating-Roof Tanks

Complex Construction: Floating-roof tanks are more complex in design and construction, which results in higher initial costs compared to fixed-roof tanks.

Maintenance Requirements: The moving parts and seals of a floating roof require regular inspection and maintenance to prevent issues such as leakage and wear. Over time, the seals may degrade, necessitating periodic replacement to maintain optimal performance.

Limited Versatility: Floating-roof tanks are typically designed for specific types of volatile liquids. Their use with non-volatile or non-hydrocarbon products may not be practical.

Weather Vulnerability: While the floating roof itself can effectively seal against liquid loss, exposure to heavy rain, snow, or debris can introduce operational challenges. Proper drainage and protection mechanisms are necessary to maintain functionality.

3. Comparative Analysis

Evaporation and Product Loss: One of the most critical differences between fixed-roof and floating-roof tanks lies in their handling of evaporation. Fixed-roof tanks, with their static vapor space, allow for greater product loss due to evaporation. Conversely, floating-roof tanks are designed to minimize this issue by reducing the volume of vapor above the liquid.

Safety Considerations: Floating-roof tanks offer improved safety by mitigating the risk of vapor accumulation. However, they require vigilant maintenance to ensure that the seals and roof mechanisms are in good condition. Fixed-roof tanks, while simpler, require additional safety installations to manage potential vapor buildup.

Cost Implications: Fixed-roof tanks have lower upfront construction and maintenance costs, making them a cost-effective choice for non-volatile liquids or scenarios where evaporation loss is not a significant concern. Floating-roof tanks, on the other hand, entail higher construction expenses but offer long-term savings through reduced product loss for volatile liquids.

4. Conclusion

The choice between a fixed-roof tank and a floating-roof tank depends on several factors, including the type of liquid being stored, budgetary considerations, environmental impact, and safety requirements. Fixed-roof tanks are more economical and versatile for a wide range of liquids, while floating-roof tanks excel in minimizing evaporation and enhancing safety for highly volatile substances. Industries should weigh these factors carefully to determine which tank type best aligns with their operational goals and regulatory compliance standards.

By understanding the strengths and weaknesses of both fixed-roof and floating-roof tanks, stakeholders can make informed decisions that optimize storage efficiency and safety while balancing costs.