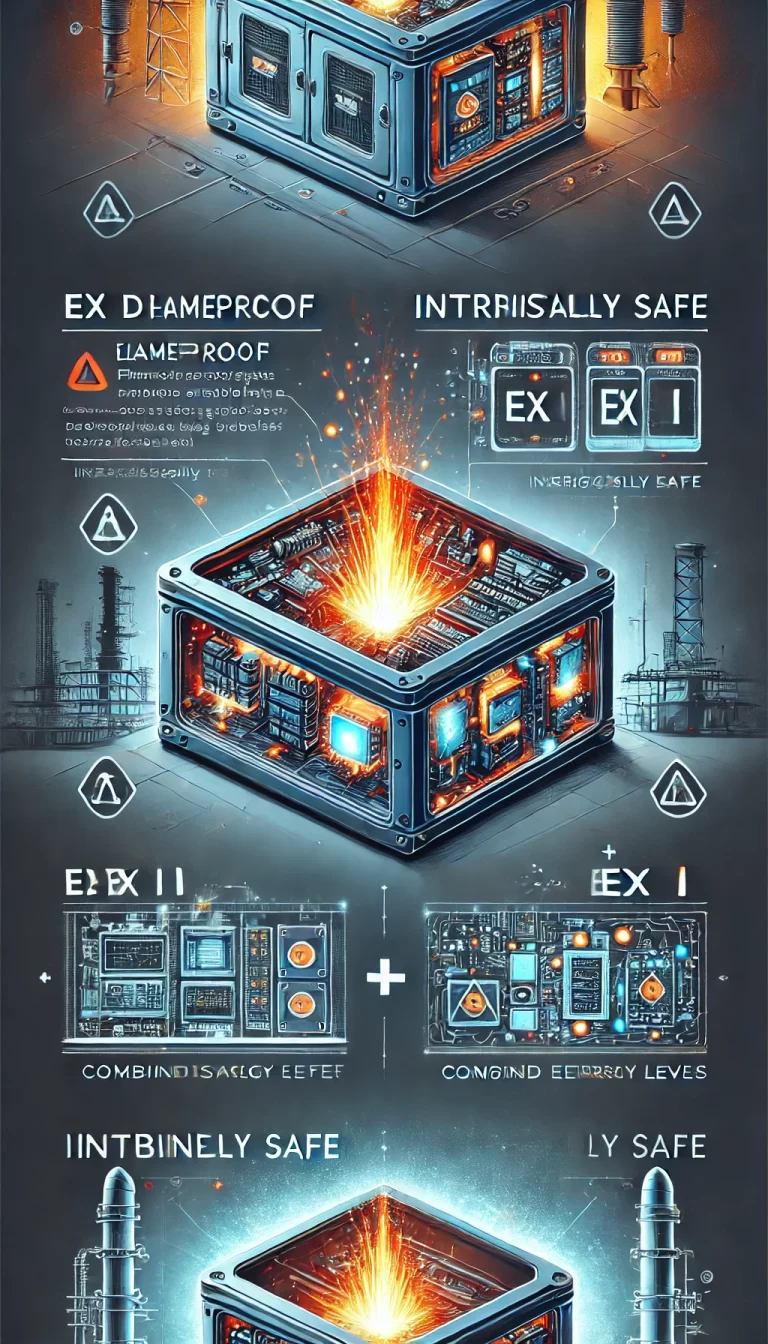

In industrial and hazardous environments, the use of electrical equipment must adhere to strict safety standards to prevent any potential ignition of explosive gases, vapors, or dust. To meet these requirements, specialized explosion-proof types of equipment are used, each designed to function under specific conditions and safety principles. The most common types are flameproof (Ex d), intrinsically safe (Ex i), and combined flameproof and intrinsically safe (Ex d + Ex i). This article explores each of these types in detail, highlighting their principles, features, and typical applications.

1. Flameproof Type (Ex d)

Definition and Principle: The flameproof type, also known as ‘Ex d,’ is designed to contain an explosion within its housing and prevent the transmission of any flames or sparks to the surrounding environment. This type is used for electrical devices where there is a potential for internal arcing, sparking, or hot surfaces that could ignite explosive gases.

Design Features:

Robust Enclosure: The enclosure of Ex d equipment is built to withstand an internal explosion without rupturing or allowing flames to escape.

Flame Path: The equipment is constructed with flame paths (such as gaps or threaded joints) that cool the escaping gases sufficiently to prevent ignition of the external atmosphere.

Material Strength: The housing material is made from strong metals capable of withstanding high internal pressures.

Typical Applications: Flameproof equipment is commonly found in oil refineries, chemical plants, and other industries where high-voltage or

2. Intrinsically Safe Type (Ex i)

Definition and Principle: Intrinsically safe equipment, labeled as ‘Ex i,’ operates on the principle that the electrical circuit is designed in such a way that, even under fault conditions, it cannot release enough energy to cause ignition. This type is particularly suitable for environments where low-power equipment is sufficient.

Design Features:

Energy Limitation: The circuits are designed to limit electrical energy (current and voltage) so that it remains below the ignition threshold for explosive gases or dust.

Protection During Faults: Ex i equipment maintains its safety profile even when components fail, ensuring that no single fault leads to a dangerous situation.

Safe Components: The use of certified zener barriers or isolators ensures that external energy sources do not compromise the intrinsic safety of the circuit.

Typical Applications: Intrinsically safe designs are used in devices that handle monitoring, measurement, and communication, such as sensors, transmitters, and data loggers in hazardous zones.

3. Combined Flameproof and Intrinsically Safe Type (Ex d + Ex i)

Definition and Principle: The combined type, which merges the characteristics of both Ex d and Ex i, provides enhanced safety by offering both robust containment and energy limitation. This dual-protection approach is essential for equipment that needs to maintain high operational safety while incorporating sensitive electronic circuits.

Design Features:

Dual Protection: The outer shell provides flameproof protection (Ex d), while the internal circuits are designed to be intrinsically safe (Ex i), ensuring that any energy present within the device is incapable of igniting the surrounding atmosphere.

Higher Reliability: Combining the two methods reduces risk, particularly in high-stakes environments where equipment failure can lead to catastrophic consequences.

Complex Systems: This type is ideal for equipment that must perform critical functions involving both high power and low-power signal processing.

Typical Applications: Ex d + Ex i equipment is used in complex operations like automated control panels, multi-functional monitoring systems, and integrated process controllers, especially in petrochemical facilities and large-scale manufacturing plants.

Conclusion

Understanding the distinctions between flameproof (Ex d), intrinsically safe (Ex i), and combined flameproof and intrinsically safe (Ex d + Ex i) types of equipment is vital for ensuring safety in hazardous industrial environments. Ex d provides robust containment for internal explosions, Ex i minimizes the risk of ignition through energy limitation, and the combined Ex d + Ex i approach offers comprehensive safety by integrating both methods. Selecting the appropriate type depends on the specific operational needs and the level of risk present in the working environment.