In industrial production, instrumentation plays a critical role in monitoring, controlling, and optimizing various production processes. Proper selection and configuration of instruments, whether in the process flow or electrical systems, ensure efficiency, safety, and product quality. This article dives into the essential aspects of maintaining process and electrical systems by discussing workflow validation, equipment selection, pipeline inspection, and electrical system requirements. These measures are vital for enhancing the stability, safety, and reliability of industrial operations.

Part 1: Process Section

1. Process Workflow

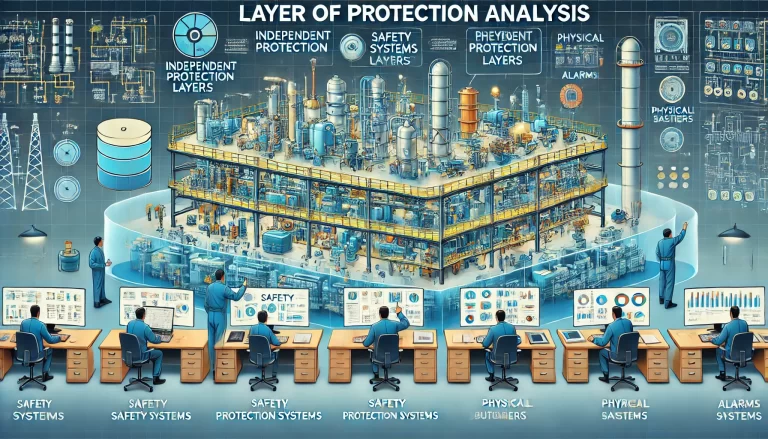

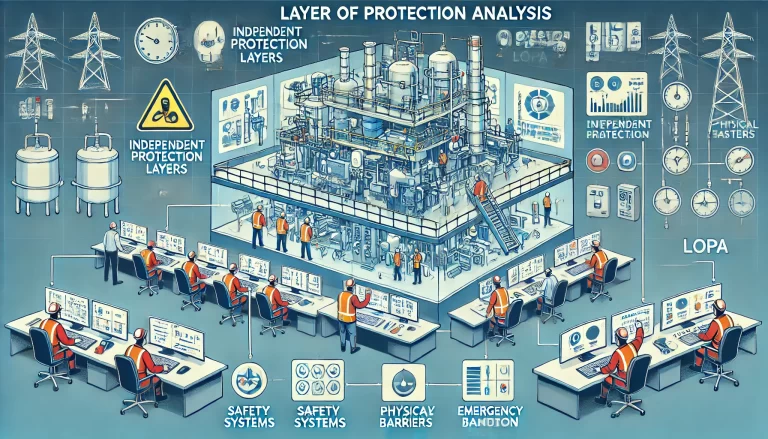

A crucial step in ensuring a smooth process flow is verifying that each operational unit aligns with design specifications, with no missing steps. Every operation, from the start of production to the shutdown phase, must reflect the original design and cover all required stages without omissions. This verification includes identifying any possible bottlenecks or misconfigurations that could disrupt workflow.

Moreover, it is essential to confirm the material flow directions within the system. Verifying that no reverse flows or dead zones exist within the material pathways helps avoid potential inefficiencies or hazards. For example, if there is any backward movement of materials or accumulation in dead zones, this could cause contamination, unexpected reactions, or system clogs, leading to production downtime. Systematic examination of flow rates, material direction, and critical control points within the workflow ensures that the entire production process operates at maximum efficiency and safety.

Another critical consideration is the setting of process parameters, which impacts the overall stability of the production system and the quality of the end product. Key parameters like temperature, pressure, and flow rate must be verified and optimized according to production requirements. Instruments should have sufficient accuracy and responsiveness to report these parameters in real-time, allowing operators to make informed adjustments as needed. This optimization is crucial, as even minor discrepancies in these values can result in reduced product quality or safety issues.

2. Equipment Selection

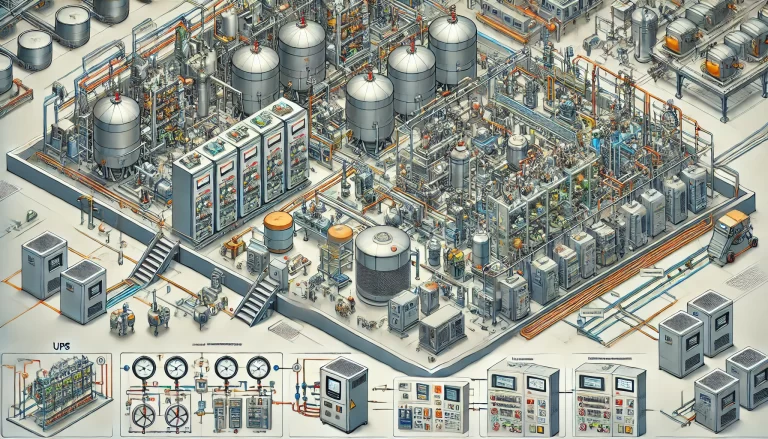

The selection of equipment must be aligned with the requirements of the specific industrial process. Equipment specifications and models should comply with design requirements and withstand the operational demands of parameters such as flow rate, temperature, and pressure. Proper selection of materials, especially those in contact with process chemicals, is also essential for avoiding corrosion or material degradation. For instance, a system exposed to corrosive substances should use corrosion-resistant materials like stainless steel or specific alloys to extend the equipment’s life.

Additionally, having standby or backup equipment is a necessity for ensuring continuous operation, particularly in cases where a main component may need maintenance or replacement. Backup systems should be readily accessible and configured to take over immediately when needed, minimizing the risk of downtime. This setup is particularly important for critical components, such as pumps or valves, where immediate replacement is vital to maintaining flow continuity and preventing delays.

3. Piping System

The piping system is a backbone of industrial process systems, and thus it requires meticulous inspection. Verifying that the pipes meet the design specifications for diameter and wall thickness is fundamental, as these parameters determine the pipe’s ability to handle expected pressure and flow rates. For example, a pipe with inadequate thickness may be at risk of bursting under pressure, leading to potentially hazardous leaks or spills.

The method of connection, such as welding or flange connections, must also suit the process requirements. Each connection should be inspected to prevent issues that may arise from weak or improperly installed joints. Additionally, clear labeling on pipes, indicating medium type and flow direction, is essential for operational safety and maintenance ease. Such labeling helps operators quickly identify lines during regular checks or emergencies, minimizing human error and improving response time.

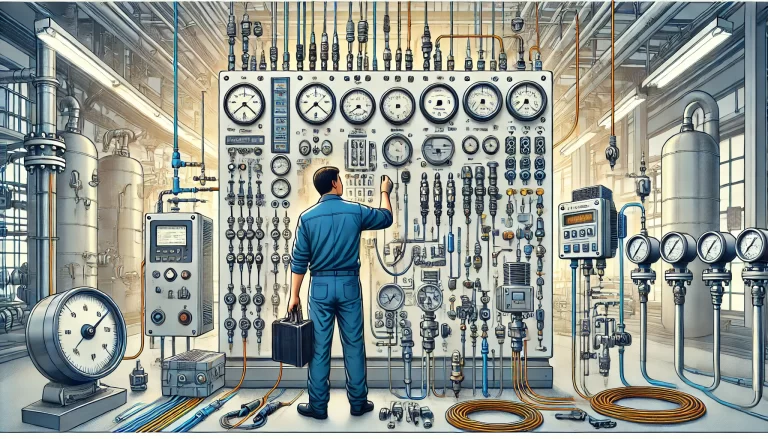

4. Valves and Instruments

Valves and instruments in a process system play a critical role in controlling and monitoring various parameters. Ensuring that valves match the type, size, and specification required by the system design is crucial for operational control. Valves should function smoothly, providing responsive control over flow rates and directions as needed.

Instrumentation positioning and specification are equally important. Instruments should be installed at precise locations, with the correct range, accuracy, and signal stability to offer dependable data. Safety components, such as pressure relief valves and rupture discs, should be periodically calibrated to ensure they respond effectively to pressure deviations. Regular calibration and inspection confirm that these safety mechanisms will activate as intended in the case of an anomaly, preventing system failures and protecting personnel.

Part 2: Electrical Section

1. Power Distribution System

The power distribution system ensures that all equipment in the facility receives stable and reliable power. The specifications and models of the main power supply lines should match the facility’s design requirements. Reliable grounding is essential for preventing electrical hazards like short circuits or power surges that could damage equipment or endanger personnel.

Power distribution components such as transformers and switchgear should align with the required parameters and be securely installed. These elements must handle the current and voltage requirements while protecting against fluctuations or overloads. Protective devices like circuit breakers, overload protection, and fuses should be appropriately rated and regularly inspected to mitigate any potential faults.

2. Lighting System

A well-planned lighting system is crucial for safe and effective work environments, especially in areas where precise operations are performed. The placement of lighting fixtures should ensure optimal brightness across all workspaces. This includes task lighting for detailed work areas and general lighting for broader zones. Additionally, the power layout for lighting should conform to safety standards to reduce any risk of electric shock or short circuits.

Emergency lighting is equally essential, especially in high-risk areas or areas requiring continuous monitoring. Emergency lighting should comply with safety regulations and provide reliable illumination in case of power outages, allowing personnel to safely evacuate or continue essential operations as needed.

3. Power System

In the power system, the selection of motors is critical to ensure operational efficiency and effectiveness. Motors should be selected based on their power capacity to meet the demands of the equipment they drive. Control methods, such as motor start-up and speed regulation, should align with process needs. For instance, variable speed drives may be needed for certain operations, allowing for adjustments to match different process conditions.

The installation of cable trays and conduits is also important for the durability and safety of power systems. Cable trays should be firmly secured and laid out logically to prevent stress or damage from external forces. Proper organization of these trays reduces the chance of wear or accidental disconnection, enhancing the overall reliability of the power system.

Conclusion

In summary, an optimized instrumentation and electrical system setup is essential for maintaining high levels of efficiency, safety, and reliability in industrial operations. Through meticulous checks on process workflow, equipment selection, pipeline configuration, and electrical systems, companies can reduce risks and enhance operational continuity. Taking these steps not only ensures compliance with industry standards but also contributes to sustainable, high-quality production outcomes.