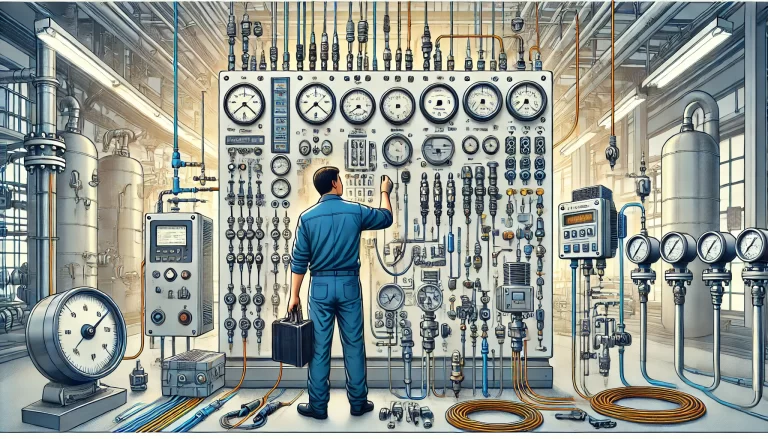

In today’s rapid development of industrial automation and instrumentation technology, various instruments are closely integrated into production processes. However, malfunctions are inevitable during operation, and troubleshooting is often a challenging task. Understanding general patterns of instrument malfunctions is essential, as it not only helps us quickly locate issues but also extends the lifespan of the instruments. How can we analyze malfunctions scientifically to achieve twice the result with half the effort?

Step 1: Identify

When an instrument malfunctions during operation, consider the following aspects:

For pneumatic instruments:

- Leakage: Since pneumatic instruments rely on compressed air, any leakage can cause deviation or failure. Common leakage points include joints, rubber hoses, seals, and gaskets, especially parts made from nylon or rubber that may degrade over time.

- Blockage: Air may contain moisture, dust, and oily substances that accumulate in throttling components, causing partial or full blockage. Components such as throttling holes, nozzles, and baffles can be impacted, especially in humid weather.

- Jamming: With minimal driving torque, increased friction at any point may cause mechanisms to jam or respond slowly. This is common in linkages, pointers, and mechanical parts.

2. For electric instruments:

- Poor Contact: Causes include oxidation of plug-in boards and terminals, loose connections, and partial wire disconnections.

- Open Circuit: Thin wiring may break easily during operation, while blown fuses or component faults can also cause open circuits.

- Short Circuit: Exposed wires touching each other or component failures are common causes.

- Loose Parts: Mechanical parts like slides, pointers, and screws may loosen, as seen in both pneumatic and electric instruments.

Step 2: Repair

Here’s an example:

Consider a situation with an electric recording controller set to measure temperatures from 50-150°C, with the pointer at its maximum.

- Observe Before Acting: When a malfunction occurs, don’t rush; observe the trends. If the pointer moves slowly to the end, it is likely a process issue. Sudden movements to the endpoint often indicate sensor or secondary instrument issues.

- External Before Internal: Begin by eliminating external issues before inspecting internal ones. For example, if a measurement pointer shifts to its minimum, the issue is external. Otherwise, the problem is likely internal.

- Mechanical Before Electrical: Mechanical failures are generally more frequent and easier to identify than electrical or signal transmission failures.

- Whole System Before Specific Parts: After ruling out mechanical issues, examine the whole circuit, dividing it into segments if necessary to isolate the problem accurately.

By narrowing the problem area, troubleshooting becomes more straightforward.