In industrial environments such as flour mills, pharmaceutical plants, and chemical manufacturing facilities, airborne dust particles can pose serious risks. When dust particles are suspended in the air at certain concentrations, even a small spark or increase in temperature can trigger a potentially devastating explosion. To mitigate such risks, dust explosion-proof technology has been developed specifically for these environments. However, dust explosion-proofing differs significantly from traditional explosion-proof designs used for gas or vapor-rich environments. Let’s explore how dust explosion-proof instrumentation works and understand the key differences from traditional explosion-proof systems.

What is Dust Explosion-Proof Instrumentation?

Dust explosion-proof instrumentation is designed to prevent explosive reactions caused by combustible dust in industrial settings. In many industries, tiny dust particles (like those in flour or coal) can be ignited under specific conditions, causing rapid combustion. Dust explosion-proofing protects sensitive equipment from such hazards, ensuring safe and uninterrupted operations.

Key Components of Dust Explosion-Proof Design

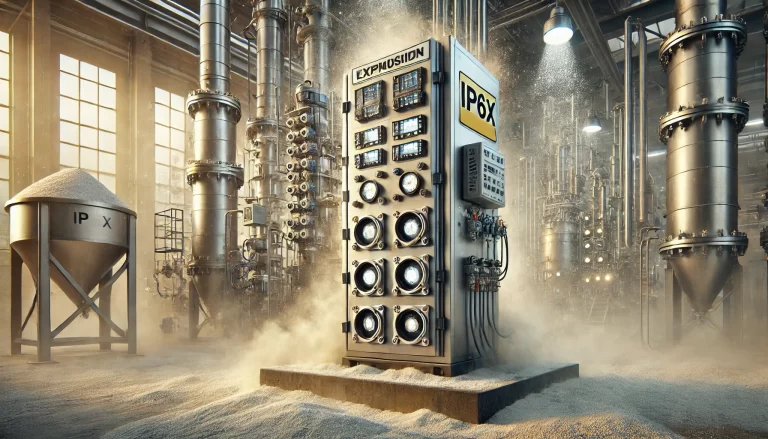

Enclosure Integrity and Sealing:

One of the primary features of dust explosion-proof instrumentation is its highly secure enclosure, which is designed to be dust-tight. The enclosure prevents dust particles from infiltrating the sensitive internal components of the instrument. This tight sealing, often requiring an IP6X rating or higher, ensures complete dust exclusion and is critical to prevent ignition of the dust particles.Enhanced Mechanical Strength:

In addition to sealing, the enclosure is built to withstand both external and internal pressures that may arise if an internal ignition does occur. The structural integrity prevents the enclosure from breaking or cracking, thus stopping flames or hot gases from escaping and igniting the external environment.Temperature Control and Ventilation:

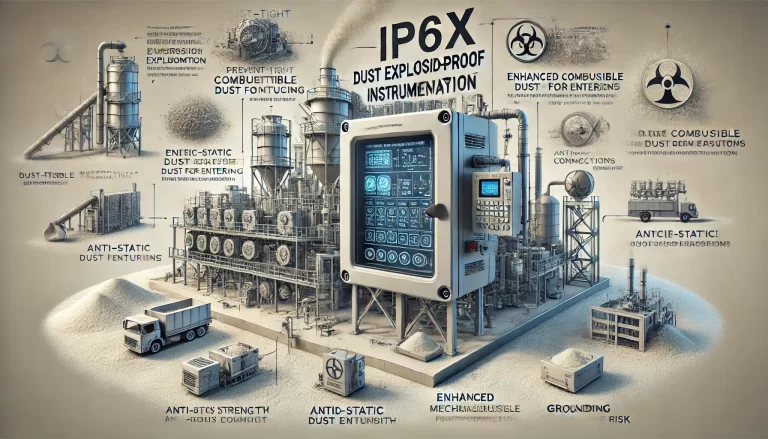

Internal temperature control is another critical factor in dust explosion-proof instrumentation. Dust particles can settle and accumulate on surfaces over time. If the surface temperature rises due to poor ventilation, it can cause dust to auto-ignite. For this reason, dust-proof equipment often has specialized ventilation designs or cooling mechanisms to manage heat and prevent dust accumulation from reaching dangerous temperatures.Anti-Static Coatings and Grounding:

Static electricity is a common cause of dust explosions. To counter this, many dust explosion-proof enclosures are coated with anti-static materials and designed with grounding capabilities. This precaution prevents static electricity buildup, minimizing the chance of accidental sparking.

Key Differences Between Dust Explosion-Proof and Traditional Explosion-Proof Instrumentation

While both dust and gas explosion-proof designs aim to prevent catastrophic explosions, they differ significantly in their structure, purpose, and design considerations.

Protection Target:

- Dust Explosion-Proof: Dust-proof designs are tailored for environments with combustible dust particles, such as grain, coal, and wood-processing industries.

- Traditional (Gas) Explosion-Proof: Traditional explosion-proof designs are meant for environments containing explosive gases and vapors, typically found in petrochemical, oil, and gas industries.

Focus on Sealing and Dust Prevention:

Dust explosion-proof instrumentation emphasizes preventing any dust from entering the enclosure. This means that the enclosure is not only pressure-resistant but also dust-tight, focusing on both exclusion and temperature control. Traditional explosion-proof systems, however, are primarily designed to contain internal explosions, focusing more on the pressure integrity of the enclosure rather than complete dust-tightness.Temperature and Ventilation Design:

Dust environments require careful temperature management, as dust layers on hot surfaces can ignite spontaneously. Therefore, dust-proof equipment includes provisions to control temperature, like ventilation holes or cooling systems. Conversely, traditional explosion-proof designs mainly concentrate on keeping the internal gases contained and rarely require dedicated cooling mechanisms.Ingress Protection (IP) Ratings:

The IP rating is a standard indicating the degree of protection provided by an enclosure against foreign objects and moisture. Dust explosion-proof designs generally require a higher IP rating (such as IP6X) to ensure complete dust exclusion, whereas traditional explosion-proof systems may not require as strict a rating in this regard.Internal and External Pressure Management:

In dust explosion-proof equipment, pressure management is mostly about maintaining the enclosure’s integrity against dust infiltration and controlling temperature. In traditional explosion-proof systems, however, the design focus is to contain and withstand the pressure generated by any potential internal explosion without allowing it to spread externally.

Practical Applications and Industry Standards

Dust explosion-proof instrumentation is essential for industries where combustible dust is present, including:

- Agriculture and Food Processing: Grain mills, flour processing, and sugar refineries.

- Pharmaceuticals: Many pharmaceutical plants generate fine powders that can become explosive in large quantities.

- Mining and Coal Processing: Coal dust is highly combustible and poses a significant explosion risk.

- Wood Processing and Paper Mills: Dust from wood and paper fibers can easily ignite and spread if proper protections aren’t in place.

Standards governing dust explosion-proof and explosion-proof instrumentation vary but often include guidelines from organizations like ATEX (for the European Union), IECEx, and NFPA (for the United States). Compliance with these standards is essential to ensure equipment safety and operational integrity.

Conclusion

Dust explosion-proof and traditional explosion-proof systems are both critical safety measures, but each serves a different purpose. Dust explosion-proof designs emphasize sealing, temperature control, and anti-static measures to prevent ignition in dust-prone environments. Traditional explosion-proof systems focus on containing potential explosions within the instrument’s enclosure in gas-rich environments. Understanding the unique requirements of each type of explosion-proofing ensures that industrial facilities can mitigate the risk of explosions effectively, protecting both equipment and personnel.

By implementing proper explosion-proof technologies, industries can maintain safer operations and reduce the risks associated with combustible dust and gas environments.