Due to the continuous and highly automated nature of production in chemical enterprises, automated instruments are widely used. Among these, transmitters are a commonly used and diverse type of instrument. They measure various process parameters such as pressure, flow, and liquid level.

Transmitter types can be classified based on the number of signal and power lines, as either two-wire or four-wire systems. Two-wire systems combine data and power lines, while four-wire systems have separate data and power lines. In recent years, intelligent transmitters have become far more prevalent than non-intelligent ones. Depending on the power source, transmitters are divided into pneumatic and electric types, though pneumatic transmitters are rarely used today.

Transmitters can also be categorized based on their application settings, such as intrinsically safe or explosion-proof types.

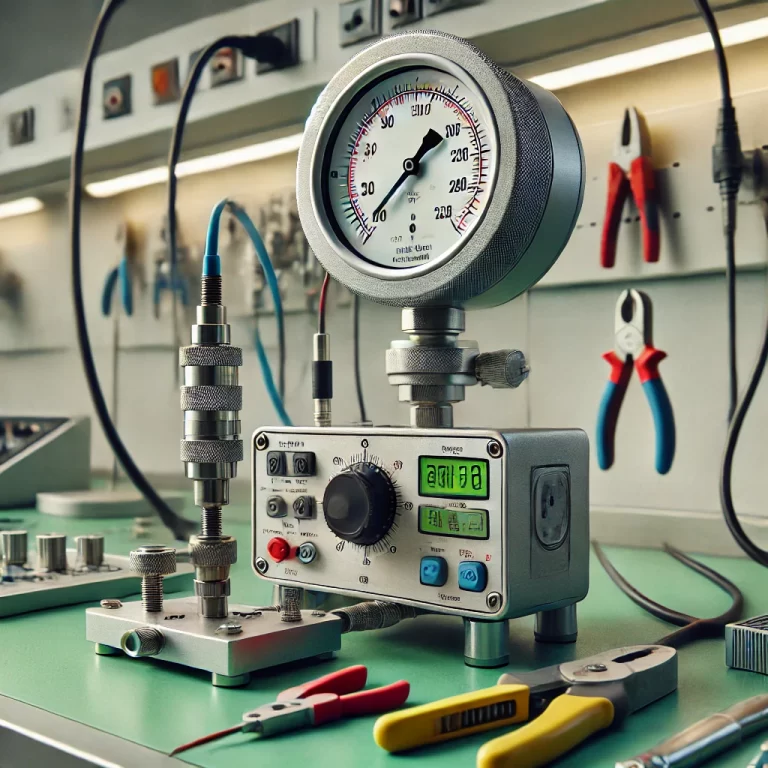

1. Overview of Pressure and Differential Pressure Transmitters

These transmitters measure pressure or the difference between two pressure points (differential pressure). They can also be used to indirectly measure other parameters like liquid levels. For example, to measure liquid levels in a container under normal pressure, a single pressure transmitter is sufficient, while two transmitters are required for containers under pressure to measure both upper and lower liquid levels.

Isolated transmitters can be classified into “remote” and “integrated” types. Remote transmitters use a strengthened capillary to connect an outer diaphragm box with a measuring diaphragm box. Integrated transmitters combine the outer diaphragm and transmitter into one unit. Isolated types often use threaded connections for easier installation, though they are more complex and expensive.

2. Key Selection Principles

When selecting a transmitter, considerations include:

- Properties of the measured medium

- Cost-effectiveness

- Ease of installation and maintenance

For high-viscosity, crystallizable, or highly corrosive mediums, isolated transmitters are necessary. Temperature, working pressure, and economic factors should also be considered. For higher temperatures (200°C to 400°C), high-temperature models should be selected.

3. Selection of Pressure Transmitters

The primary consideration when selecting a pressure transmitter is pressure. Most industrial pressure gauges measure “gauge pressure” (which includes positive and negative values).

For long-distance or high-precision measurements, pressure transmitters or sensors should be used. For less stringent accuracy requirements, resistance-type, inductance-type, or Hall-effect sensors are more appropriate. Additionally, the installation site must be explosion-proof if required by the environment.

4. Selection of Differential Pressure Transmitters

Factors to consider include:

- Measurement range and accuracy

- Operating environment (such as the presence of harmful gases)

- Characteristics of the measured medium (e.g., corrosive, viscous, or prone to crystallization)

- Operating conditions like temperature and pressure variations

- The complexity and size of the equipment being measured

- Instrument versatility to reduce costs and spare parts

For example, for tanks with high-viscosity liquids or materials prone to crystallization, a double-flange differential pressure transmitter may be the best choice. In cases where opening holes is not possible (like in high-pressure equipment), radiation level meters might be selected.

5. Conclusion

When selecting a transmitter in chemical enterprises, a comprehensive approach should be taken. Both technical operability and economic feasibility should be ensured, and the selection process should also consider future maintenance needs. As technology advances, the range of available transmitters will expand, but the basic selection principles will remain largely the same.