In industrial environments such as oil, gas, petrochemical, and chemical industries, safety is paramount. Many systems and concepts have been developed to mitigate risks and protect both personnel and infrastructure. Among these systems are SIS (Safety Instrumented System), SIF (Safety Instrumented Function), and SIL (Safety Integrity Level). Other related terms like SILa and SIL0 are also used, though they are less formal. These concepts are vital in the design, evaluation, and implementation of safety measures in industries with high-risk processes. Let’s explore these concepts in greater detail and discuss their engineering applications.

1. Safety Instrumented System (SIS)

A Safety Instrumented System (SIS) is an engineered set of hardware and software controls designed to take preventive or mitigating actions in the case of hazardous events. Its purpose is to maintain safe operating conditions by monitoring the process for specific dangerous conditions and initiating protective actions automatically when those conditions are detected.

Components of SIS:

- Sensors: These devices monitor process variables like temperature, pressure, flow, and level. They detect hazardous deviations from normal operating parameters.

- Logic Solvers (Controllers): This component processes inputs from sensors and determines whether the process is moving into an unsafe state. Safety Programmable Logic Controllers (PLCs) are commonly used as logic solvers.

- Final Elements (Actuators): Final control elements (such as valves, pumps, or breakers) act upon the logic solver’s decision to mitigate a potentially dangerous situation, such as shutting off the flow of a dangerous chemical or shutting down a piece of equipment.

SIS is an integral part of the overall safety strategy in industrial systems. It’s designed according to international standards like IEC 61508 and IEC 61511, which ensure that the system provides a high level of protection against accidents.

Engineering Application:

- In a refinery: If a vessel’s pressure rises beyond safe limits, a SIS may detect the high pressure, trigger an alarm, and shut down the relevant equipment or divert the process flow to prevent catastrophic failure.

- In offshore oil platforms, SIS might act to automatically close wellheads if dangerous gas levels are detected.

2. Safety Instrumented Function (SIF)

A Safety Instrumented Function (SIF) is a specific function within a SIS, aimed at preventing a specific hazardous event. Each SIF consists of the sensor(s), logic solver, and actuator(s) that work together to manage a particular risk. In essence, a SIS may consist of multiple SIFs, each designed to address different hazardous scenarios.

For example, a plant might have one SIF responsible for detecting high pressure in a pipeline and shutting it off, while another SIF might detect a chemical leak and close the relevant valves to contain it.

Engineering Application:

- Over-pressure protection: In a chemical processing unit, a SIF may monitor pressure in a reactor. If the pressure exceeds safe levels, the system closes a relief valve or vents gases safely to prevent a rupture or explosion.

- Emergency shutdown systems (ESD): These are another common form of SIF, designed to shut down the entire system in a controlled manner in the event of a critical safety breach, such as a fire or toxic gas release.

3. Safety Integrity Level (SIL)

Safety Integrity Level (SIL) is a measure of the reliability of a safety instrumented function in terms of its ability to reduce risk. The SIL rating system ranges from SIL 1 (lowest level of safety integrity) to SIL 4 (highest level). Each SIL level corresponds to a specific range of Probability of Failure on Demand (PFD), which is the likelihood that a system will fail when called upon to act. The higher the SIL level, the lower the PFD, meaning the system is more reliable in preventing dangerous events.

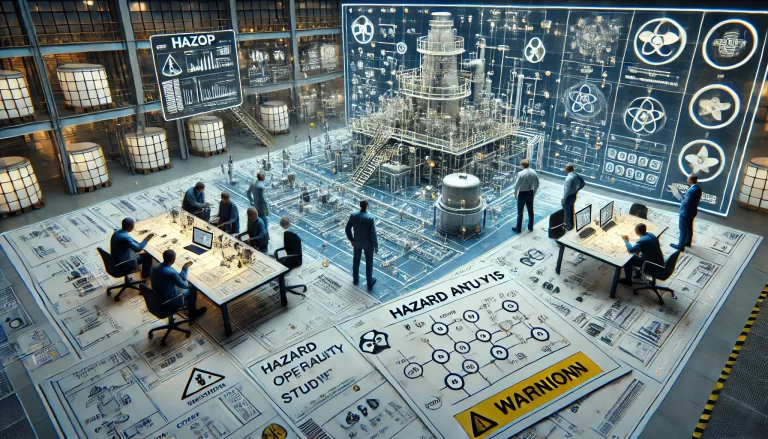

The required SIL level for any SIF is determined through risk assessment methods, such as LOPA (Layer of Protection Analysis). This evaluation considers the likelihood of the hazardous event and the severity of its potential consequences.

SIL Levels:

- SIL 1: Provides a PFD of 0.1 – 0.01, meaning a 10% to 1% chance of failing when demanded.

- SIL 2: Provides a PFD of 0.01 – 0.001, meaning a 1% to 0.1% chance of failing when demanded.

- SIL 3: Provides a PFD of 0.001 – 0.0001, meaning a 0.1% to 0.01% chance of failure.

- SIL 4: Provides a PFD of 0.0001 – 0.00001, the most stringent and rarest application, often reserved for critical situations.

Engineering Application:

- In nuclear power plants, SIL 3 or SIL 4 systems might be required for critical shutdown processes to prevent reactor damage or a meltdown.

- In offshore oil drilling, SIL 2 or SIL 3 systems might be used in blowout preventers (BOPs) to stop the uncontrolled release of oil or gas during drilling operations.

4. SILa and SIL0

SILa (Safety Integrity Level achievable or assumed) and SIL0 are informal terms used in engineering discussions.

- SILa refers to the level of SIL that is either achievable or assumed during the design process. When engineers design safety systems, they estimate the SIL they expect to reach based on system configuration, reliability, and redundancy. This helps guide decisions about how much investment and complexity are required in the system.

- SIL0 is sometimes used to refer to systems that do not meet any formal SIL rating. It means that the system has little to no safety integrity level and is generally not acceptable in environments where safety is a critical concern. A SIL0 system may indicate that additional layers of protection or redesign are required to improve safety.

Engineering Application:

- SILa is useful during the design phase, allowing engineers to set targets for safety and performance before full-scale system implementation.

- SIL0 could be a designation for outdated or insufficient safety systems that need upgrading. For instance, in older industrial facilities, systems designed before modern safety standards might be classified as SIL0, indicating a need for significant improvement to meet current safety standards.

Conclusion

In industries with hazardous processes, ensuring safety is a complex and essential task. SIS, SIF, and SIL provide structured frameworks for designing, assessing, and implementing safety systems that prevent accidents and mitigate risks. While SIS and SIF focus on the functionality of safety systems, SIL provides a quantifiable measure of how reliable those systems are in preventing hazardous events. Informal terms like SILa and SIL0 offer additional context during the design and assessment phases.

Together, these systems and concepts help ensure that industrial processes operate within safe boundaries, protecting both people and assets from the potentially catastrophic consequences of system failures. As industries evolve and processes become more complex, the role of these safety systems in engineering applications will only grow in importance.