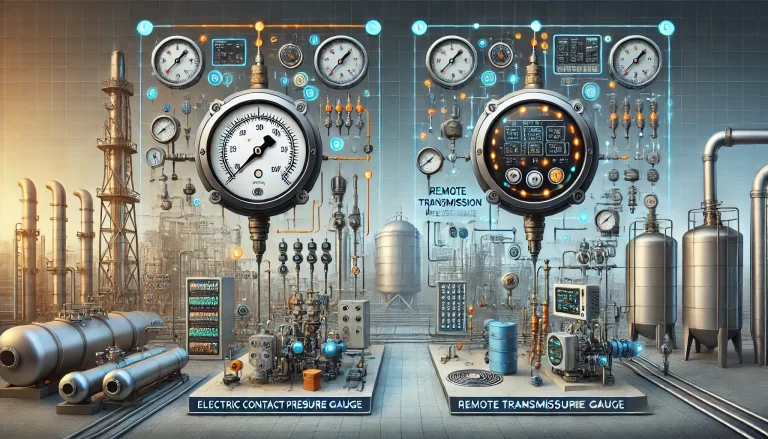

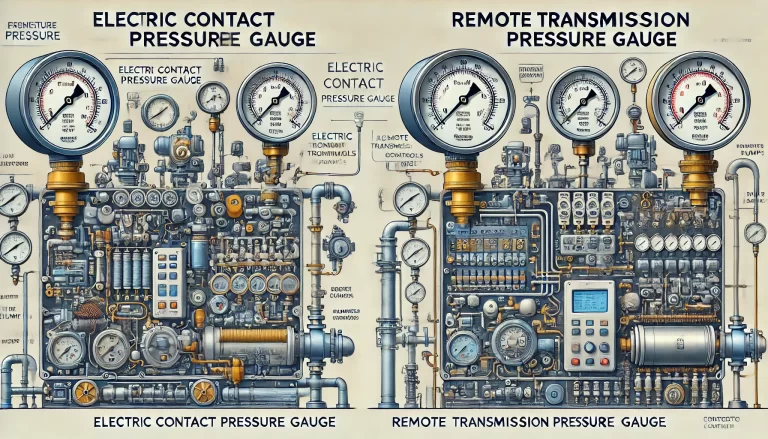

Pressure gauges are critical instruments used to measure the pressure in a variety of systems, including industrial machinery, pipelines, and processing systems. Among the different types of pressure gauges, Electric Contact Pressure Gauges and Remote Transmission Pressure Gauges stand out for their specialized functionalities. While they may appear similar at first glance, these two types of pressure gauges are designed for different applications, and understanding their distinctions is essential for selecting the right gauge for specific industrial needs.

1. Basic Functionality

Electric Contact Pressure Gauges:

Electric Contact Pressure Gauges are mechanical pressure gauges equipped with electrical contacts that activate or deactivate an electrical circuit when the pressure reaches a predetermined threshold. This capability allows them to be used for pressure monitoring and control, making them useful in systems that require automated responses based on pressure levels. When a defined pressure is reached—either high or low—the electric contact within the gauge will close or open, triggering an external action, such as activating an alarm, switching a pump on or off, or initiating a control relay.

For instance, in a boiler system, an Electric Contact Pressure Gauge could be used to shut off a burner once a specific pressure is reached, ensuring safety and operational control.

Remote Transmission Pressure Gauges:

Remote Transmission Pressure Gauges, on the other hand, are designed to convert pressure readings into electrical signals that can be transmitted over long distances to a remote monitoring station or control system. These gauges are typically equipped with a sensor that converts the mechanical pressure value into an analog or digital signal, such as a 4-20mA current loop, which is the industry standard for long-distance signal transmission.

This makes Remote Transmission Pressure Gauges ideal for systems where real-time remote monitoring is necessary, such as in large industrial plants, oil pipelines, and chemical processing facilities. Instead of having operators manually check pressure levels on-site, the pressure information is continuously transmitted to a central control room, allowing operators to monitor the system’s status from a distance.

2. Key Applications

Electric Contact Pressure Gauges:

The primary application of Electric Contact Pressure Gauges is automatic control and alarm systems. They are commonly used in systems that require on-site control of equipment based on pressure levels. Some common application areas include:

- Boilers: Used to shut off the burner when a preset pressure level is reached.

- Pumps: Triggered to start or stop based on system pressure.

- Compressors: Used to activate or deactivate compressors in response to pressure changes.

Electric Contact Pressure Gauges are typically used in systems where pressure-based control and safety mechanisms are critical to prevent overpressure or system failure.

Remote Transmission Pressure Gauges:

These gauges are particularly suited for systems that require continuous and remote monitoring of pressure levels over long distances. They are used in applications such as:

- Petroleum and Chemical Plants: Where the pressure of fluids in pipelines and tanks needs to be monitored continuously from a central location.

- Water Supply Systems: Used to track pressure levels in different sections of the distribution network and detect any pressure drops that may indicate leaks.

- Automation Systems: Integrated with SCADA (Supervisory Control and Data Acquisition) systems to provide real-time data on pressure, allowing for better process control.

In these environments, real-time data transmission helps ensure that operators can quickly respond to any anomalies in pressure, which could lead to system malfunctions, leaks, or even dangerous conditions.

3. Signal Output

Electric Contact Pressure Gauges:

The signal output from an Electric Contact Pressure Gauge is mechanical in nature, with the electrical contacts physically opening or closing based on the pressure level. This makes them simple but effective for use in systems where the goal is to trigger a specific action at a defined pressure point. The contacts are often connected to relays, alarms, or motors, enabling the pressure gauge to act as a control switch.

Remote Transmission Pressure Gauges:

In contrast, Remote Transmission Pressure Gauges provide electrical output signals that can be either analog or digital. Commonly, the gauge converts pressure into a 4-20mA signal, which can then be interpreted by control systems. The advantage of this electrical output is that it allows the pressure data to be transmitted over long distances without significant signal loss. Additionally, many modern Remote Transmission Pressure Gauges can provide real-time digital data that can be integrated with more sophisticated data collection and monitoring systems.

4. Structural Differences

Electric Contact Pressure Gauges:

The design of Electric Contact Pressure Gauges is based on mechanical pressure gauges, with the addition of electrical contacts. These contacts are usually adjustable, allowing the user to set the pressure thresholds at which the contact will close or open. The mechanical movement of the pressure gauge remains visible, but its primary function is to activate or deactivate the contact rather than transmit the pressure data elsewhere.

These gauges are typically more rugged and designed for on-site operation, as they do not require advanced electronics for signal transmission.

Remote Transmission Pressure Gauges:

Remote Transmission Pressure Gauges integrate both mechanical and electronic components. The pressure is detected by a sensor, which converts the pressure into an electrical signal. The electronics in the gauge then process this signal and prepare it for transmission. This makes these gauges slightly more complex in design compared to Electric Contact Pressure Gauges, as they need to ensure signal integrity over potentially long distances.

These gauges may also feature additional functionalities, such as digital displays or signal conditioning units, that enhance their ability to provide accurate, real-time data in remote locations.

5. Summary of Key Differences

| Feature | Electric Contact Pressure Gauge | Remote Transmission Pressure Gauge |

|---|---|---|

| Primary Function | Pressure control and automation | Remote pressure monitoring and data transmission |

| Output Type | Mechanical contact (open/close circuit) | Electrical signal (e.g., 4-20mA, 0-10V) |

| Application | Boilers, pumps, compressors (on-site pressure control) | Oil pipelines, chemical plants (remote monitoring) |

| Signal Transmission | None (local control only) | Long-distance (centralized control rooms) |

| Complexity | Simple, mechanical operation | Includes sensor and electronic signal conversion |

Conclusion

Choosing between an Electric Contact Pressure Gauge and a Remote Transmission Pressure Gauge depends on the specific needs of the application. If the goal is to control and automate equipment based on pressure levels at a local site, Electric Contact Pressure Gauges are ideal. However, if remote monitoring and real-time data transmission are required, especially in large-scale industrial processes, Remote Transmission Pressure Gauges are the better choice.

Both types of gauges are invaluable in modern industrial systems, ensuring safety, efficiency, and accuracy in pressure monitoring and control. Understanding their differences will help in making the right selection based on the operational requirements of a particular system.