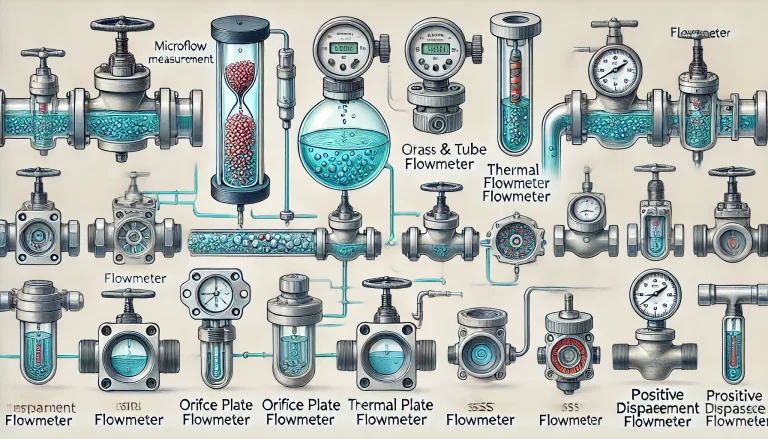

Microflow measurement refers to the process of determining the flow rate of fluids in very small quantities. This process is used across a wide variety of industries, particularly in fields like pharmaceuticals, chemicals, and precision engineering. Measuring such low volumes accurately presents certain challenges. Several instruments are available to accomplish this task, and they share common characteristics that make them suitable for microflow measurement. This article will discuss the key aspects of microflow measurement methods and provide a comparison of different types of flowmeters used for this purpose.

Key Characteristics of Microflow Measurement:

Susceptibility to Blockage: One of the primary challenges in microflow measurement is the small diameter of the measurement instruments. These narrow passageways can easily become clogged with impurities or solid particles in the fluid. As a result, it is essential to install a filter with an appropriate mesh size before the flowmeter to prevent debris from blocking or jamming the instrument.

Ease of Calibration: Microflow meters, due to their limited measurement range, can be easily calibrated both offline in laboratory settings and online during operation. Instruments like float flowmeters and thermal mass flowmeters benefit from relatively simple calibration procedures. If the actual fluid used in the measurement differs from the one used during factory calibration, high-accuracy requirements might necessitate recalibration with the actual fluid before the instrument is put into service. Similarly, after extended use or if there are doubts about the instrument’s accuracy, recalibration using the real fluid is recommended.

Pressure Loss Considerations: Unlike in large-scale flow measurement, users of microflow instruments typically do not prioritize minimizing pressure loss. Therefore, when calculating the diameter of the orifice plate, higher differential pressure values are often allowed within acceptable limits to improve accuracy.

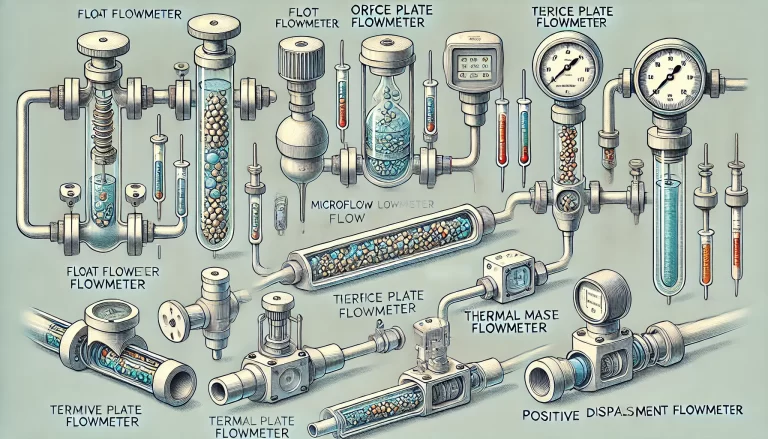

Comparison of Common Microflow Instruments:

Several types of flowmeters are commonly used in microflow measurement, each with its own strengths and weaknesses.

Glass Tube Float Flowmeters: Glass tube float flowmeters are the most cost-effective solution but are limited in their application. They are best suited for measuring clean, transparent fluids with low viscosity. However, the float can become stuck if solid impurities are present in the fluid, making them less reliable for fluids that are not entirely clean.

Metal Tube Float Flowmeters: Metal tube float flowmeters, unlike their glass counterparts, do not require fluid transparency but still have similar requirements for cleanliness and low viscosity. The float in these meters can also be affected by solid particles in the fluid, leading to malfunction.

Orifice Plate Flowmeters: Compared to float flowmeters, orifice plate flowmeters are less sensitive to the cleanliness of the fluid. As long as the diameter of the solid particles is smaller than the orifice, the particles will be carried downstream, minimizing the risk of blockage. Orifice plates are simple in structure, easy to clean, and durable, making them a popular choice in process control environments. Additionally, they are easy to adjust for different flow ranges, and the differential pressure transmitters used with orifice plates are common and widely used in process monitoring.

Thermal Mass Flowmeters: Thermal mass flowmeters have a wide range of measurement, allowing them to measure extremely low flow rates. These meters find applications in specialized situations where accurate measurement of very small quantities is required. They are especially useful when the flow rate lower limit needs to be as small as possible.

Positive Displacement Flowmeters: The main advantage of positive displacement flowmeters is their ability to measure fluids with higher viscosity. These meters also provide higher accuracy, making them a popular choice in applications like oil metering. Their robust construction allows them to handle more challenging fluid conditions than other types of microflow instruments.

Conclusion:

Microflow measurement presents unique challenges due to the small size of the instruments and the sensitivity to impurities and fluid conditions. Careful selection of the appropriate type of flowmeter is essential, depending on the specific application and the properties of the fluid being measured. Float flowmeters, orifice plate flowmeters, thermal mass flowmeters, and positive displacement flowmeters each offer different advantages, making them suitable for a variety of use cases in microflow measurement. With proper calibration and maintenance, these instruments can deliver the accuracy needed for high-precision processes.