1. What is grounding?

In a power system, grounding refers to the electrical connection made between the neutral point, casing, or support of equipment and a grounding device using a conductor to establish a reliable connection with the earth.

2. What is neutraling?

Neutraling refers to the connection of the metallic casing of electrical equipment to the system’s neutral line.

3. Why is grounding and neutraling necessary?

The purpose of grounding and neutraling is twofold:

- First, to ensure the normal operation of electrical equipment (e.g., working grounding).

- Second, to ensure personal and equipment safety (e.g., protective grounding and neutraling). While there are other types of grounding like repeated grounding, lightning protection grounding, and electrostatic shielding grounding, their functions align with these two purposes.

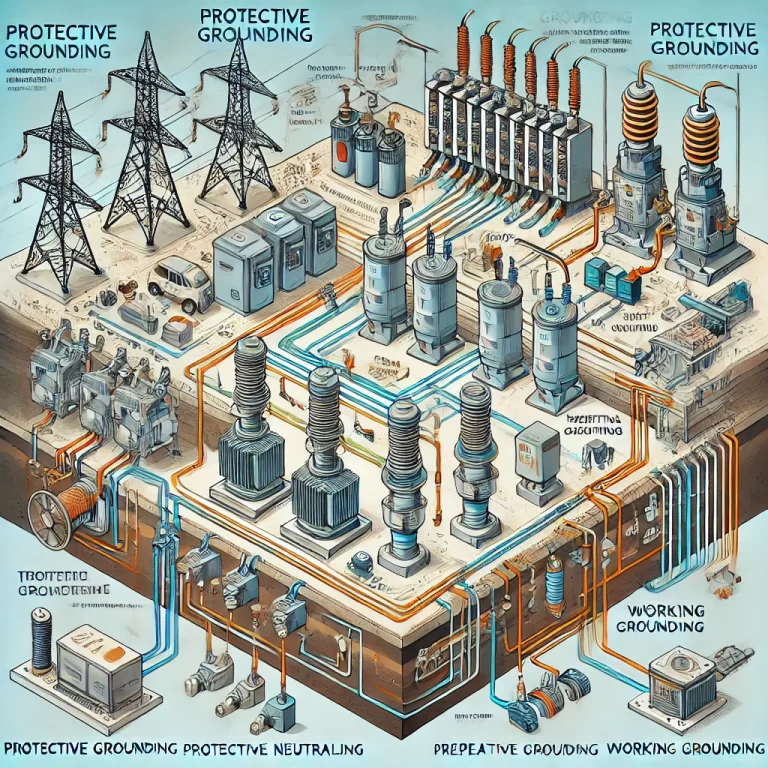

4. What is protective grounding?

Protective grounding connects the metallic casing and frame of electrical equipment reliably to the earth using a grounding device. It is used in low-voltage systems where the power source’s neutral point is not grounded. If the insulation of electrical equipment is damaged, and the metal conductor touches the casing, the grounding system reduces the voltage on the casing. When a person touches the casing, the grounding system creates two parallel circuits between the casing and the earth. The smaller the grounding resistance of the equipment, the smaller the current passing through the human body, thus preventing electric shock.

5. What is protective neutraling?

In a low-voltage system where the neutral point of the power source is grounded, protective neutraling involves connecting the metal casing of electrical equipment to the neutral line or neutral trunk line (used in three-phase, three-wire circuits). If the insulation of the electrical equipment is damaged, causing a short circuit between the phase and neutral lines, the neutral line’s low resistance will allow a large short-circuit current to flow. This will cause the protective switch or fuse in the circuit to trip, cutting off the power, making the casing non-electrified, and eliminating the risk of electric shock.

6. What is repeated grounding?

Experience has shown that grounding the neutral line only at the power source is not sufficiently safe. Therefore, the neutral line should also be grounded at points along the overhead low-voltage lines, branches, or where cables/overhead lines enter a building (except where the distance from the grounding point is less than 50m). Grounding in buildings and connecting the neutral line to the distribution or control panels’ grounding device is also called repeated grounding.

7. What is working grounding?

Working grounding connects the neutral point of a transformer to the ground. Its primary function is to stabilize the system voltage, reduce the risk of overvoltage caused by single-phase grounding, and prevent insulation breakdown. Secondly, in grounded distribution networks, single-phase ground fault currents can reach several amps to tens of amps, making fault detection easier. Without working grounding, the voltage between the other two phases and the ground rises to line voltage, which is dangerous. This situation can last because the grounding current is small, making the distribution network unsuitable for operation.

8. What types of grounding are used in hazardous chemical enterprises?

There are three types of grounding commonly used:

- Electrical grounding

- Anti-static grounding

- Lightning protection grounding

Electrical equipment grounding is crucial for explosion prevention, while anti-static and lightning protection grounding is essential for explosion prevention in oil depots.

9. What are grounding devices, grounding bodies, and grounding wires?

A grounding device includes both the buried grounding body and the grounding wire connected to it. Grounding serves different purposes, such as working grounding, protective grounding, repeated grounding, and lightning protection grounding. Though each has specific features, they share the same basic design and installation principles. A grounding device includes a grounding body and grounding wire:

- Grounding body: A metal conductor buried underground, in direct contact with the soil.

- Grounding wire: The metal conductor connecting the grounding body, grounding grid, and electrical equipment’s grounding points.

The grounding body can be natural or artificial, as can the grounding wire.

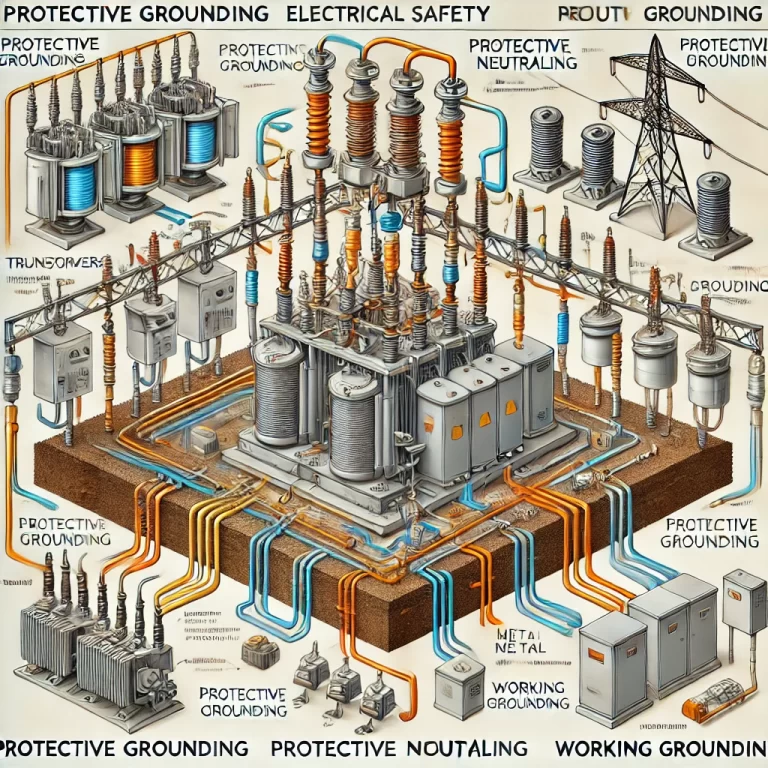

Differences Between Protective Grounding, Protective Neutraling, Repeated Grounding, and Working Grounding

1. Applicability:

- Protective Grounding: Suitable for power grid systems where the neutral point is not grounded, like rural grids or small independent systems. It serves as the primary safety measure in systems where neutraling is not possible.

- Protective Neutraling: Used in directly grounded three-phase four-wire or three-phase five-wire systems, common in industrial and residential power distribution networks. It is effective for equipment requiring quick disconnection of fault power, like large machines.

- Repeated Grounding: Used in directly grounded low-voltage systems, especially in systems utilizing protective neutraling. It is critical in areas with complex electrical environments or poor grounding conditions, such as construction sites.

- Working Grounding: Applicable in any power system that requires a stable operating baseline, from power plants to distribution stations.

2. Connection Methods:

- Protective Grounding: The metal casing of equipment is connected to the grounding body, which can be an artificial grounding device or natural elements like building steel.

- Protective Neutraling: The metal casing is connected directly to the system’s neutral line.

- Repeated Grounding: The neutral line is connected to the grounding device at one or multiple points.

- Working Grounding: The transformer or generator’s neutral point is connected directly to the grounding device.

3. Working Principles:

- Protective Grounding: When the casing becomes electrified, current flows through the grounding device to the earth, minimizing the risk of electric shock.

- Protective Neutraling: If a short circuit occurs, the protective device quickly disconnects the power.

- Repeated Grounding: Reduces the voltage on equipment casings and improves power quality by reducing neutral line potential.

- Working Grounding: Stabilizes the system’s voltage and limits the rise in voltage during single-phase grounding faults.