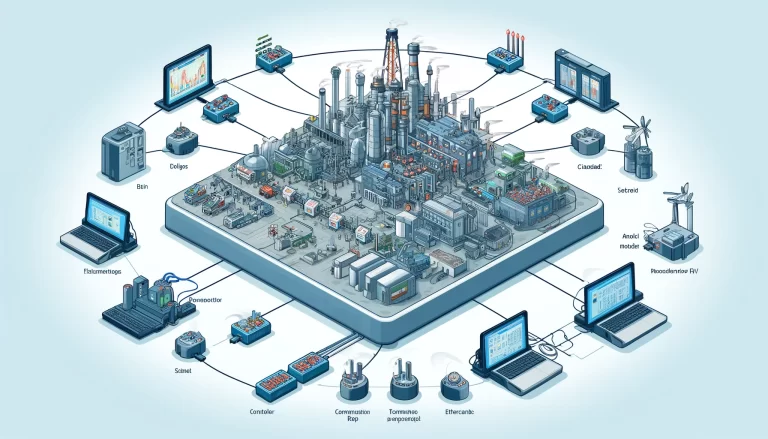

Automation systems involve the use of electrical and mechanical components to perform tasks with minimal human intervention. Whether it’s industrial machinery, robotics, or control systems, electronic components form the backbone of these technologies. If you’re pursuing studies in automation, mastering the fundamentals of key electronic components is critical. Below, we’ll explore eight essential components every automation student must understand in detail.

1. Resistor

- Function: A resistor is a passive electronic component that restricts the flow of electrical current in a circuit.

- Purpose: It’s used to control voltage levels, limit current, and protect sensitive components from excessive current.

- Application: Resistors are found in almost every electronic circuit. In automation, they are often used in sensor circuits, timing circuits, and as part of voltage dividers to ensure the correct voltage is applied to certain parts of the system.

- Types: Fixed resistors, variable resistors (potentiometers), and thermistors (which change resistance with temperature).

2. Capacitor

- Function: Capacitors store and release electrical energy in the form of an electric field.

- Purpose: They are used for filtering, energy storage, and smoothening power supply in circuits.

- Application: In automation, capacitors are commonly found in motor start circuits, filtering noise in power supplies, and stabilizing voltage levels. They also play a critical role in smoothing out voltage fluctuations in control systems.

- Types: Electrolytic, ceramic, and film capacitors are some of the most commonly used types.

3. Inductor

- Function: An inductor stores energy in a magnetic field when electrical current passes through it.

- Purpose: It resists sudden changes in current and is used in filtering, tuning circuits, and energy storage.

- Application: In automation systems, inductors are used in power supply circuits, motor control applications, and signal filtering. They help manage power transfer in systems that use alternating current (AC) or have fluctuating power levels.

- Types: Air-core inductors, iron-core inductors, and toroidal inductors.

4. Diode

- Function: A diode allows electrical current to flow in one direction while blocking it in the reverse direction.

- Purpose: Diodes are essential for rectification, converting alternating current (AC) to direct current (DC), protecting circuits from voltage spikes, and regulating voltage levels.

- Application: In automation, diodes are used in power supplies, signal demodulation, and protection circuits (e.g., flyback diodes for motors). They are also used in sensor interfaces to prevent damage from reverse current.

- Types: Rectifier diodes, Zener diodes, and Light Emitting Diodes (LEDs).

5. Transistor

- Function: A transistor is a semiconductor device that can act as an electronic switch or amplifier.

- Purpose: It can control a large current or voltage with a smaller signal, making it fundamental in the switching and amplification of electrical signals.

- Application: In automation systems, transistors are used in switching circuits, signal amplification, motor control, and microcontroller interfaces. For instance, they control relays or drive motors by acting as a bridge between a low-power control signal and a higher-power load.

- Types: Bipolar Junction Transistors (BJT) and Field Effect Transistors (FET).

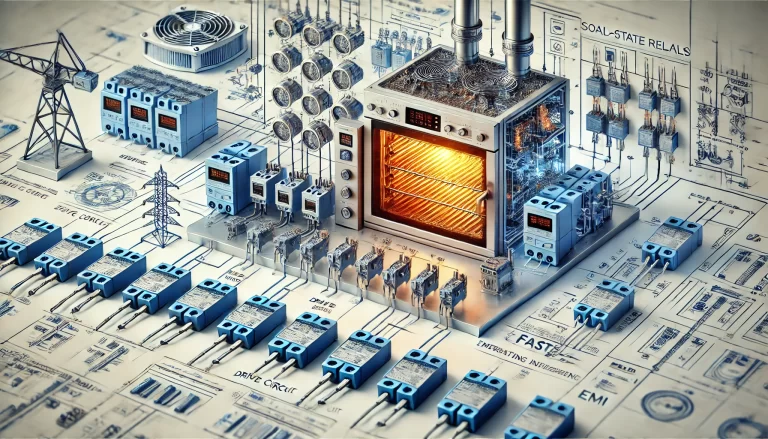

6. Relay

- Function: A relay is an electromagnetic switch that uses a small electrical current to control a larger current in another circuit.

- Purpose: It allows control of high-power devices (like motors and heaters) by low-power control systems (like microcontrollers).

- Application: Relays are heavily used in industrial automation for controlling motors, lighting systems, and safety circuits. They provide electrical isolation and allow one circuit to switch another, often with different power levels or voltages.

- Types: Electromechanical relays, solid-state relays, and reed relays.

7. Optocoupler (Optoisolator)

- Function: An optocoupler transfers electrical signals between two isolated circuits using light. It consists of an LED and a photosensitive receiver (like a photodiode) inside the same package.

- Purpose: It provides electrical isolation between circuits, ensuring that high-voltage systems do not interfere with low-voltage control circuits.

- Application: In automation, optocouplers are used to protect sensitive control systems, such as microcontrollers or PLCs, from high-voltage or noisy power circuits. They are often found in communication interfaces, motor drives, and power control systems.

- Types: Phototransistor and photovoltaic optocouplers.

8. Sensor

- Function: A sensor detects physical parameters such as temperature, pressure, light, motion, or distance, and converts them into electrical signals.

- Purpose: Sensors are the input devices in automation systems that allow the system to interact with the physical world by gathering data about environmental conditions.

- Application: Automation systems rely heavily on sensors to provide feedback for control systems. They are used for process control, robotics, environmental monitoring, and safety systems. For example, temperature sensors regulate heating systems, while proximity sensors control robotic movements.

- Types: Temperature sensors, pressure sensors, proximity sensors, and infrared sensors.

Conclusion

For anyone diving into the field of automation, having a deep understanding of these eight core electronic components is essential. Each component plays a unique and critical role in the operation of automated systems, from signal processing to power control. Mastering their functions, applications, and variations will provide you with the foundation needed to design, analyze, and troubleshoot automation systems effectively.