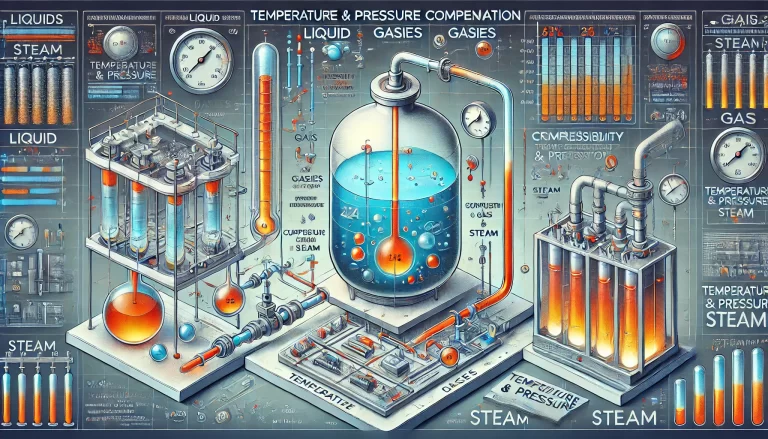

Temperature and pressure compensation strategies are crucial in ensuring accurate measurements and efficient control in processes involving fluids such as liquids, gases, and steam. Variations in temperature and pressure can significantly alter the physical properties of these fluids, including their density, volume, and pressure, making it essential to apply the right compensation techniques for each type of fluid. In this article, we will delve into effective temperature and pressure compensation strategies based on the unique characteristics of liquids, gases, and steam.

1. Temperature and Pressure Compensation for Liquids

Key Characteristics of Liquids

Liquids exhibit relatively low compressibility, meaning their volume doesn’t change much with pressure, but their density and volume can change significantly with temperature. Therefore, temperature compensation plays a more prominent role for liquids compared to pressure compensation.

Temperature Compensation for Liquids

When a liquid’s temperature increases, its molecules move more rapidly, causing the liquid to expand and reducing its density. To account for this, temperature compensation involves continuously monitoring the liquid’s temperature and adjusting the measured volume or density to reflect the actual state at a reference temperature (e.g., standard conditions). In many industries, this process is automated using sensors and control systems that apply temperature correction formulas.

For example, in the petroleum industry, the Volume Temperature Correction (V-T) formula is used to adjust the measured volume of liquid fuel to a standard reference temperature. This ensures accurate accounting and avoids discrepancies due to thermal expansion or contraction of the liquid.

Pressure Compensation for Liquids

While liquids are less compressible, high-pressure environments can still cause slight changes in their volume. In most practical applications, this effect is negligible, but in extreme conditions, pressure compensation becomes necessary. Using pressure sensors, the system can apply a correction factor to account for any compressive effects on the liquid.

Compensation Methods

- Volume Correction Factor (VCF): In cases where precise measurements are critical, industries may use lookup tables or computational methods based on temperature and pressure to calculate correction factors.

- Real-time Sensors: Automated systems equipped with temperature and pressure sensors can continuously monitor the conditions and apply real-time compensation using the appropriate formulas or databases.

2. Temperature and Pressure Compensation for Gases

Key Characteristics of Gases

Gases are highly compressible, and both temperature and pressure have significant effects on their volume and density. Therefore, compensation for both temperature and pressure is essential for accurate gas measurements and control.

Temperature Compensation for Gases

As the temperature of a gas increases, the kinetic energy of its molecules also increases, leading to an expansion in volume and a reduction in density (assuming pressure remains constant). To correct for this, gas systems often use ideal gas laws or real gas equations to compensate for temperature changes.

The Ideal Gas Law is commonly used for most gases under moderate conditions:

PV=nRT

Where:

- P is the pressure,

- V is the volume,

- n is the number of moles of gas,

- R is the gas constant,

- T is the temperature.

However, for gases under high pressure or low temperature where deviations from ideal behavior occur, real gas equations, like the Van der Waals equation, are used.

Pressure Compensation for Gases

Gases are highly sensitive to pressure changes. When pressure increases, gas molecules are compressed into a smaller volume, increasing the density. Similar to temperature compensation, pressure compensation involves using the ideal or real gas laws to calculate the changes in volume or density based on the measured pressure.

For more accurate real-world applications, particularly in industries like natural gas, the AGA-8 equation is commonly used. This complex equation accounts for the behavior of natural gas under various pressures and temperatures, providing more accurate compensation for both factors.

Compensation Methods

- State Equations: Use of the Ideal Gas Law or real gas equations (Van der Waals, Redlich-Kwong) depending on the pressure and temperature range.

- Compressed Gas Standards: For industrial gases like natural gas, specific equations such as AGA-8 are used to provide standardized temperature and pressure compensation.

- Advanced Monitoring Systems: Sensors that measure temperature and pressure continuously, feeding data into systems that apply dynamic compensation.

3. Temperature and Pressure Compensation for Steam

Key Characteristics of Steam

Steam exhibits characteristics of both gases and liquids, and its properties are strongly influenced by temperature and pressure changes. Steam can exist as saturated steam, where it is in equilibrium with water, or as superheated steam, where it behaves more like a gas. The compensation strategies for steam need to account for its phase (saturated or superheated) and the changes in its enthalpy (heat content) and density with temperature and pressure.

Temperature Compensation for Steam

When steam is heated, its enthalpy increases, especially if it reaches a superheated state. Superheated steam expands in volume as its temperature increases, and this requires accurate temperature compensation. Saturated steam, on the other hand, has a direct relationship between temperature and pressure, so temperature compensation also requires precise control over pressure.

The compensation is typically handled by referring to steam tables or using thermodynamic equations for steam that relate temperature, pressure, and specific enthalpy. For example, saturated steam at 100°C has a corresponding pressure of 1 atmosphere, but if the temperature increases beyond this, it enters the superheated region, where pressure compensation must also be factored in.

Pressure Compensation for Steam

Pressure plays a critical role in determining the phase and properties of steam. At higher pressures, the temperature at which steam becomes saturated (turns into water) increases. Hence, accurate pressure compensation is essential to avoid condensation and ensure the steam system operates efficiently.

For both saturated and superheated steam, pressure compensation relies on steam tables or software that calculates the steam’s density, volume, and enthalpy at different pressures and temperatures. These tables or systems provide correction factors based on the measured conditions.

Compensation Methods

- Steam Tables: These tables list the properties of steam (enthalpy, volume, and pressure) at various temperatures. They are widely used for both saturated and superheated steam compensation.

- Superheated Steam Equations: For superheated steam, equations or software that calculates thermodynamic properties at different pressures and temperatures are used.

- Dynamic Control Systems: Industrial systems often use real-time sensors to measure temperature and pressure, with software that performs the necessary compensation using steam tables or equations.

Conclusion

Effective temperature and pressure compensation strategies are critical to ensuring the accuracy and efficiency of fluid measurement and control systems. Liquids primarily require temperature compensation due to their low compressibility, while gases require both temperature and pressure compensation due to their high compressibility and sensitivity to these changes. Steam, with its unique phase properties, requires a more complex compensation strategy that takes both temperature and pressure into account to maintain its thermodynamic equilibrium. By applying the appropriate compensation methods, industries can achieve precise control over fluid processes, improving efficiency and reducing errors.

Temperature and pressure sensors, along with real-time monitoring and computational models, play a vital role in implementing these compensation strategies.