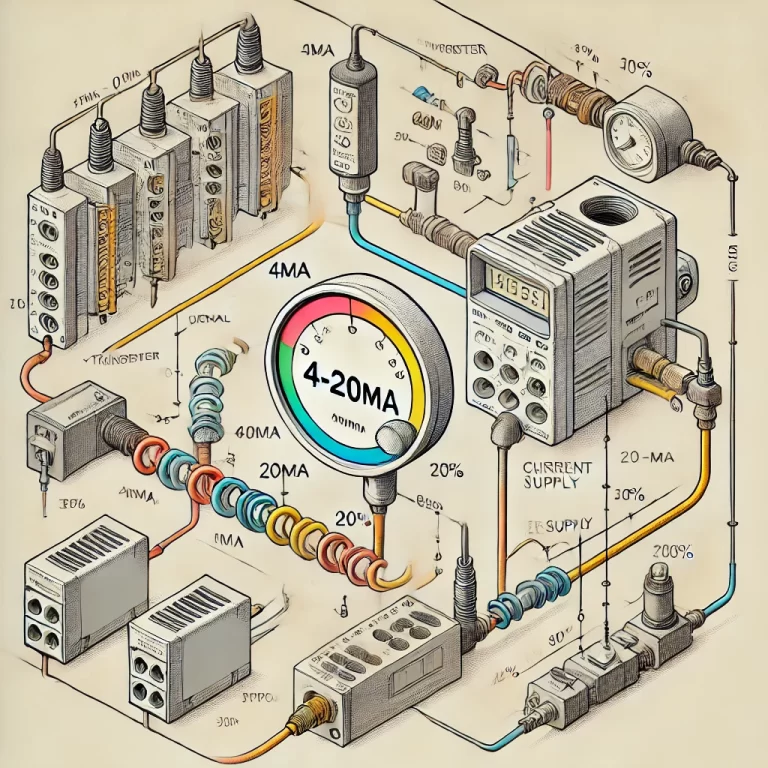

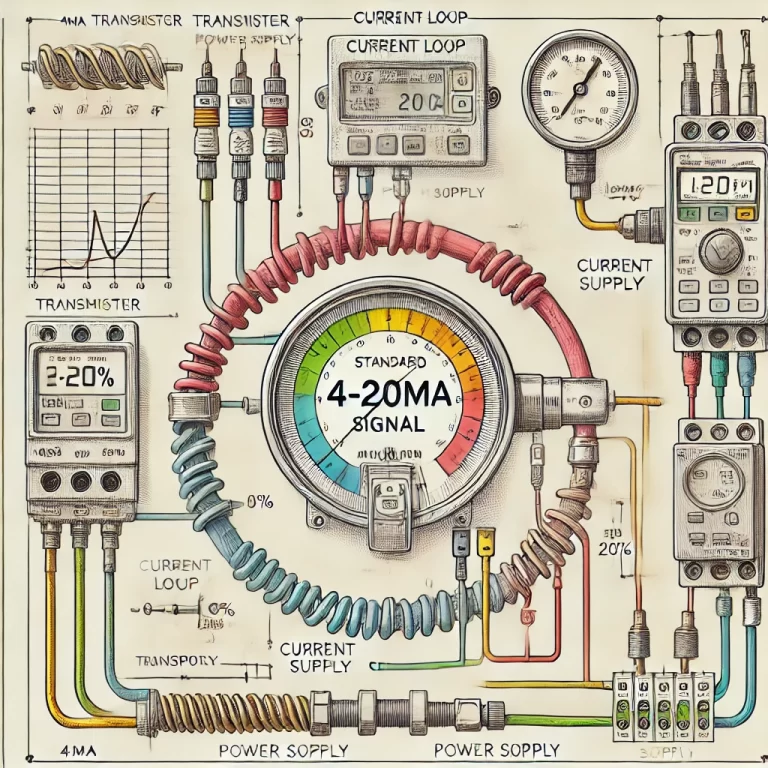

In industrial automation, transmitting accurate and reliable signals over long distances is critical for process control. One of the most widely used standards for analog signal transmission is the 4-20mA current loop. This article explores the reasons behind its popularity and effectiveness in industrial environments.

1. Strong Noise Immunity

In industrial environments, electrical noise and interference are common. Signals transmitted over long cables are particularly vulnerable to these interferences. A current signal like 4-20mA is less affected by electrical noise compared to voltage signals, because the current flowing through a conductor is less likely to be influenced by external electromagnetic fields. This ensures that the transmitted data remains accurate, even in noisy conditions.

2. Fault Detection

One of the advantages of using a 4-20mA signal, as opposed to a 0-20mA signal, is that the 4mA lower limit provides a clear distinction between a live zero (4mA) and a potential fault condition (0mA). If the current falls below 4mA, it can immediately indicate a problem, such as a broken wire or device malfunction. This makes it easier to detect and troubleshoot issues in the control system.

3. Long Distance Signal Transmission

Signals need to travel over significant distances in many industrial applications. Unlike voltage signals, which degrade over long distances due to cable resistance, current signals maintain their integrity. The 4-20mA signal is largely unaffected by the length of the cable or the resistance in the wiring, which ensures accurate readings over long distances.

4. Consistent and Reliable Signal

Current signals remain stable and accurate even with varying loads on the receiving end. This means that 4-20mA signals are much more reliable than voltage signals, where voltage drop over long distances can lead to signal loss. By using a current loop, the system can deliver consistent signal quality, ensuring precise measurements.

5. Universally Accepted Standard

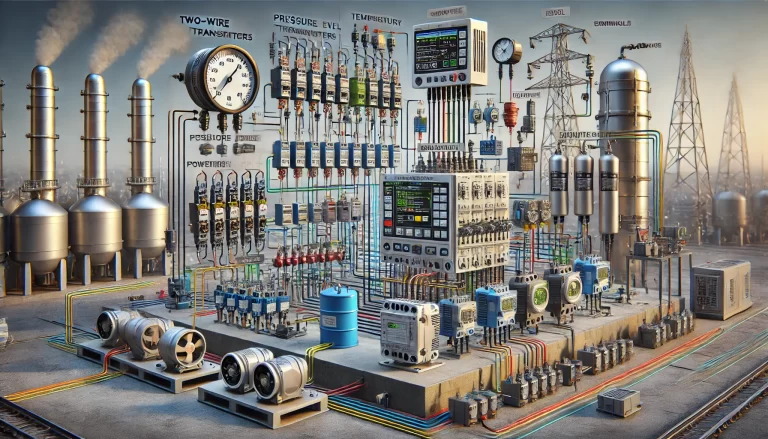

The 4-20mA signal has become the de facto standard in the industry for transmitting analog signals. This widespread acceptance means that most sensors, controllers, and actuators are designed to work with 4-20mA, allowing for easy integration across a variety of equipment. Using this standard simplifies system design and reduces compatibility issues.

Detailed Explanation:

Strong Noise Immunity: Electrical noise, especially in industrial settings where heavy machinery and high-voltage equipment are in use, can distort signals. Voltage-based signals (such as 0-10V) are susceptible to interference, leading to inaccurate readings. However, current signals (like 4-20mA) resist these effects because they rely on the flow of current rather than potential differences, making them more robust against noise.

Fault Detection: The choice of 4mA as the minimum signal instead of 0mA allows for immediate detection of wiring issues or device failures. If the signal falls to 0mA, it is a clear indication that the circuit may be open or the sensor is malfunctioning. This feature allows for quick fault diagnosis and minimizes downtime in automated systems.

Long Distance Transmission: In industrial plants, signals often need to travel from sensors to control rooms that can be hundreds or even thousands of meters apart. Voltage signals lose strength over distance due to resistance in the wires. However, current signals do not degrade in the same way, as long as the loop power supply can compensate for voltage drops across the wire’s resistance.

Consistent Signal Quality: A current loop ensures that the signal remains constant despite variations in the impedance of the receiving equipment. Whether the receiver’s input resistance is high or low, the current remains the same, delivering a precise and accurate reading.

Universally Accepted Standard: The 4-20mA standard is ubiquitous in industrial systems, ensuring compatibility between different devices from different manufacturers. This reduces the complexity of system design and allows for seamless integration, making it easier to maintain and expand systems without compatibility concerns.

The 4-20mA current loop continues to be the preferred method for analog signal transmission in industrial automation due to its durability, reliability, and ease of fault detection.