Interrupts are a crucial feature in Programmable Logic Controllers (PLC), designed to manage high-priority tasks in real-time control systems. They play a vital role in enhancing the efficiency and responsiveness of a PLC by allowing it to handle critical events immediately. This article will discuss the concept of interrupts in PLC, why they are used, their advantages, application scenarios, how interrupts are implemented, and key considerations for designing an interrupt system.

1. What is an Interrupt in PLC?

In a PLC, an interrupt is a signal that temporarily halts the normal execution of a program to address a high-priority task. This can occur due to a hardware event, timer expiration, or specific conditions in the software. When an interrupt is triggered, the PLC momentarily stops executing the main program and switches to a predefined interrupt handler or subroutine. Once the interrupt is processed, the PLC resumes the main program from the point where it was interrupted.

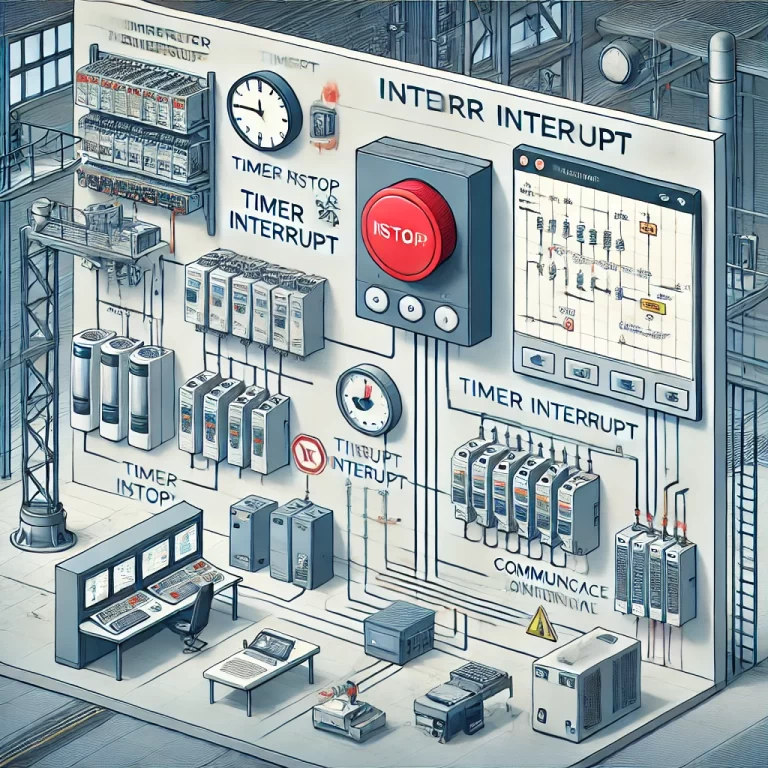

Interrupts are classified into several types:

- Hardware Interrupts: Triggered by external devices or hardware signals (e.g., emergency stop buttons or sensor signals).

- Timer Interrupts: Occur at specific time intervals to handle recurring tasks.

- Software Interrupts: Initiated by the program itself, often based on logical conditions or faults.

- Communication Interrupts: Triggered by specific communication signals or errors during data exchange between the PLC and other devices.

2. Why Use Interrupts in PLC?

Interrupts are used to ensure that critical events in a system are handled immediately, rather than waiting for the normal scan cycle of the PLC. In a typical PLC scan, the program execution follows a sequential process, where inputs are read, logic is processed, and outputs are updated. This scan cycle might take milliseconds or more, which can be too slow for urgent tasks.

By using interrupts, the PLC can respond to high-priority events with minimal delay, enabling timely actions such as emergency stops, safety shutdowns, or quick updates to critical sensors. Interrupts are essential in applications where fast responses are critical for ensuring system safety, preventing damage, or maintaining optimal operational efficiency.

3. Advantages of Using Interrupts

Using interrupts in a PLC system offers several key advantages:

- Real-Time Responsiveness: Interrupts allow the system to respond instantly to high-priority events, ensuring real-time control in industrial processes.

- Efficiency: By handling only critical tasks during an interrupt, the system avoids unnecessary delays and maintains overall program efficiency.

- Resource Optimization: Interrupts help to allocate CPU resources more effectively by focusing on important tasks rather than scanning through the entire program sequentially.

- Improved Safety: In environments where safety is paramount, interrupts ensure immediate action in case of hazardous conditions, such as equipment malfunctions or operator errors.

4. Application Scenarios

Interrupts are widely used in industrial automation and control applications. Some common scenarios where interrupts are essential include:

- Emergency Stop Systems: In manufacturing environments, an emergency stop button can trigger an interrupt, immediately shutting down machinery to prevent accidents or damage.

- Real-Time Data Acquisition: Systems that require precise timing, such as capturing sensor data at specific intervals, can use timer interrupts to ensure regular and accurate sampling.

- Fault Detection and Alarms: When a fault condition is detected (e.g., overcurrent or temperature threshold), a hardware interrupt can be used to immediately notify the system and initiate corrective actions.

- Motor Control: Interrupts can be used to monitor feedback from motion sensors or encoders and quickly adjust the control output to maintain precise motor speed or position.

- Communication Protocols: PLCs communicating with external devices, such as remote I/O modules or human-machine interfaces (HMI), can use communication interrupts to prioritize and manage incoming data without missing critical information.

5. How Interrupts Are Implemented

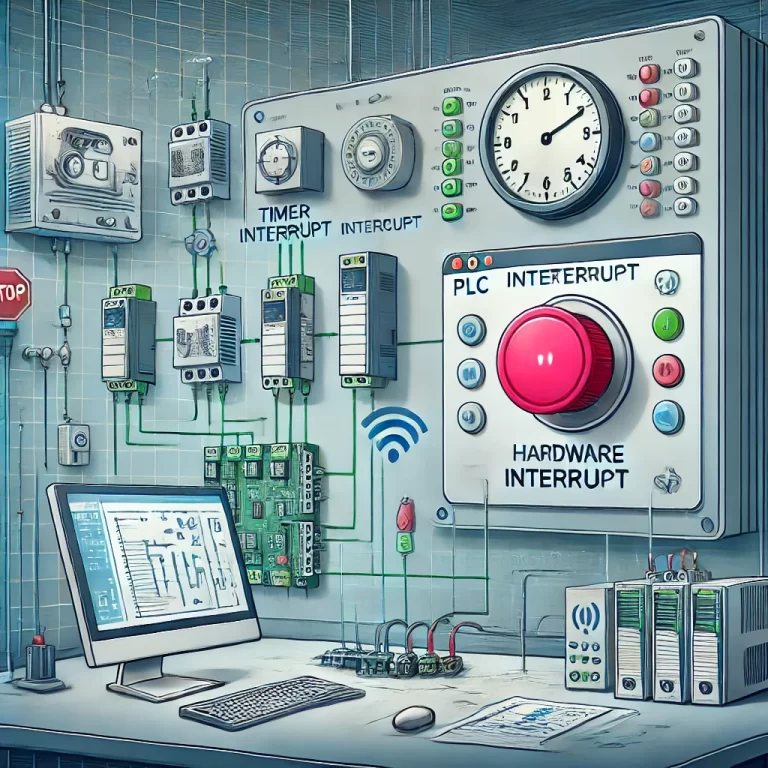

The implementation of interrupts in a PLC depends on the specific PLC model and programming environment being used. Typically, it involves configuring the following elements:

- Interrupt Triggers: These are the conditions or signals that activate an interrupt, such as a rising edge on a specific input pin or the expiration of a timer.

- Interrupt Priority: In cases where multiple interrupts can occur simultaneously, they are assigned different priority levels. Higher-priority interrupts preempt lower-priority ones.

- Interrupt Handler: When an interrupt occurs, the PLC jumps to a designated interrupt service routine (ISR) or subroutine. This is where the specific actions required by the interrupt are executed.

- Return from Interrupt: After completing the ISR, the PLC resumes the main program from where it was interrupted.

Modern PLC programming environments provide built-in functions for configuring and handling interrupts. For example, in ladder logic programming, specific blocks are used to define interrupt conditions, and these blocks are tied to ISR routines.

6. Key Considerations for Designing an Interrupt System

Designing an interrupt system for a PLC requires careful planning to ensure that it operates efficiently and reliably. The following factors should be considered:

- Interrupt Frequency: High-frequency interrupts may overload the CPU, leading to performance degradation. It’s crucial to balance the number of interrupts with the PLC’s processing capacity.

- Interrupt Latency: The time it takes for the PLC to respond to an interrupt is called latency. Ensuring minimal latency is critical for real-time applications.

- Prioritization: Assigning proper priority levels to interrupts helps manage multiple interrupt events. High-priority tasks should interrupt lower-priority ones.

- Debouncing: For interrupts triggered by mechanical devices like buttons, debouncing techniques may be necessary to prevent false triggers due to noise or contact bounce.

- Interrupt Nesting: Some PLC systems support interrupt nesting, where a higher-priority interrupt can occur while processing a lower-priority one. Careful design is needed to prevent system instability or deadlocks.

- Testing and Validation: Interrupt-driven systems should be thoroughly tested to ensure they function correctly under all possible scenarios, including edge cases and fault conditions.

Conclusion

Interrupts are a powerful feature in PLCs, enabling real-time responses to critical events in industrial automation systems. By allowing immediate processing of high-priority tasks, interrupts improve efficiency, safety, and system performance. Understanding how to implement interrupts effectively, while considering the design challenges such as prioritization and latency, is essential for optimizing the operation of PLC-controlled systems.

In summary, interrupts are indispensable in scenarios requiring fast, reliable responses, such as emergency stops, real-time data acquisition, and fault management. Properly designed interrupt systems contribute significantly to the robustness and flexibility of modern PLC-based automation solutions.