Hydrogen-related facilities pose significant safety challenges due to the flammable and volatile nature of hydrogen gas. To ensure safe operations, controlling and analyzing potential gas leaks is essential. Below are detailed solutions that integrate modern technology, real-time monitoring, and risk management strategies for effectively managing gas leaks in hydrogen environments.

1. Leak Point Analysis

- Common Leak Points: Hydrogen gas leaks can occur at several key areas, including:

- Hydrogen storage tanks

- Pipeline junctions, valves, and flanges

- Compressors and pumps

- Hydrogen refueling ports

- Risk Assessment: Regularly assess the likelihood of leaks in high-risk areas by considering factors such as temperature, pressure, and equipment integrity. Prioritize these areas for monitoring.

2. Monitoring Strategy and Sensor Placement

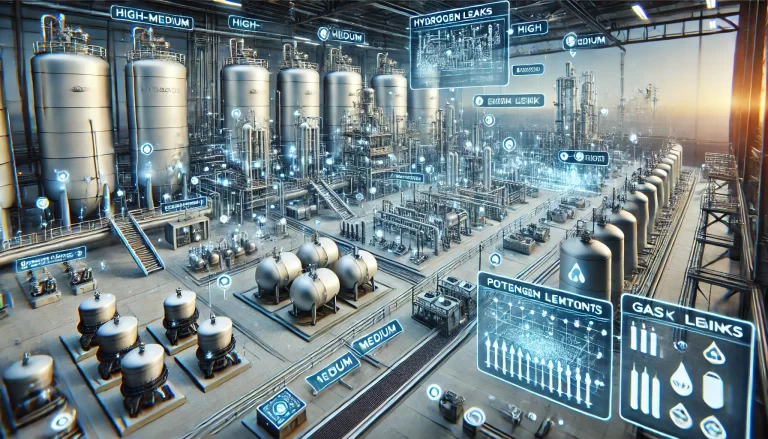

- Zoning the Facility: Divide the facility into high, medium, and low-risk zones. High-risk areas should receive the most attention in monitoring efforts.

- Hydrogen Sensor Placement: Sensors must be strategically placed around high-risk equipment and pipelines, particularly in elevated areas, as hydrogen gas is lighter than air and rises.

- High-Sensitivity Detection: Use hydrogen-specific sensors with fast response times and long operational lives.

- Layered Detection: In critical zones, multiple layers of sensors should be installed to ensure no leaks are missed.

- Redundant Systems: Implement redundant monitoring systems in critical areas to ensure continuous coverage in the event of equipment failure.

3. Real-Time Monitoring and Alarm Systems

- Real-Time Data Collection: Use IoT-enabled hydrogen sensors to provide real-time data to a central monitoring system.

- Automated Alarm Systems: Set alarm thresholds for hydrogen concentration levels. When a leak is detected, the system automatically triggers an audible alarm, sends notifications to relevant personnel, and initiates emergency protocols like ventilation or valve closures.

4. Emergency Response Systems

- Automatic Leak Control: In response to detected leaks, systems should automatically close valves in key pipelines, preventing the spread of hydrogen gas.

- Emergency Ventilation: Install emergency ventilation systems that can activate automatically in case of a hydrogen leak to dilute the gas concentration, preventing dangerous accumulations.

- Isolating Leak Zones: Equip high-risk zones with isolation mechanisms like automatic barriers or containment devices that stop the spread of leaked hydrogen.

5. Preventive Maintenance and Predictive Analysis

- Regular Maintenance: Schedule routine inspections of sensors, pipelines, and equipment to detect potential failures before they lead to leaks.

- Predictive Maintenance: Implement a predictive maintenance strategy by leveraging data collected from hydrogen sensors and operational systems. Use this data to predict equipment failures and perform preventive repairs.

- Historical Data Analysis: Continuously gather and analyze data from past leaks to identify common patterns and improve future monitoring strategies.

6. Digital Twin Technology for Risk Simulation

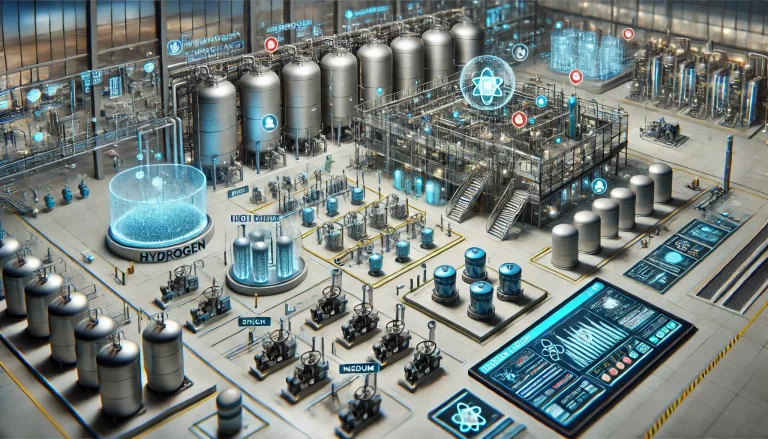

- Digital Twin Implementation: Create a virtual representation of the facility using Digital Twin technology, which can simulate real-time operations and predict the impact of hydrogen leaks.

- Simulation of Leak Scenarios: Using the Digital Twin, you can simulate potential hydrogen leak scenarios and develop more effective emergency response strategies.

- Risk Assessment: The virtual model continuously monitors equipment and environmental data to assess risk in real time.

- CFD Modeling: Apply Computational Fluid Dynamics (CFD) tools to simulate hydrogen gas dispersion in different leak scenarios, helping improve safety protocols.

7. Automated Control and Response Systems

- Smart Valve Systems: Install smart valves that automatically shut down sections of the hydrogen network when a leak is detected, preventing the spread of gas.

- Remote Shutdown and Control: Enable remote control of key systems, such as valves and ventilation, through a centralized control room that can act immediately upon leak detection.

- Redundant Safety Systems: Build redundant systems, including multiple safety valves and sensors, to provide a backup in case of failure in the primary system.

8. Optimized Hydrogen Storage and Management

- Enhanced Storage Safety: Use multi-layer protective measures in hydrogen storage facilities, including high-strength materials, secondary containment systems, and pressure relief valves to mitigate the risk of leaks.

- Pressure Relief Devices: Install pressure relief devices that automatically release excess hydrogen pressure when it exceeds safety limits, reducing the risk of catastrophic failure.

9. Proactive Risk Management Systems

- Comprehensive Risk Management Platform: Build an integrated platform that connects gas leak detection, equipment maintenance, and emergency response to ensure full-scale management of safety risks.

- Predictive Analytics: Use advanced data analytics to monitor key safety parameters in real time and predict potential accidents.

- Employee Training: Provide regular safety training for employees, teaching them how to recognize and respond to hydrogen leaks. Promote a “safety-first” culture to ensure vigilance and adherence to safety protocols.

Example of a Solution:

Hydrogen Leak Monitoring and Emergency Response System: A hydrogen storage facility employs a network of high-sensitivity hydrogen sensors connected to an automated monitoring platform. In case of a leak, the system automatically shuts down key valves, activates emergency ventilation, and notifies safety personnel through real-time alerts.

Digital Twin and Predictive Maintenance: A hydrogen production facility uses Digital Twin technology to model the facility’s operations in real time. The system monitors key components, predicts potential equipment failures, and provides maintenance alerts before a failure occurs, significantly reducing the risk of leaks.

Conclusion:

Addressing the risks of hydrogen gas leaks in facilities requires a multi-faceted approach. By integrating modern technologies such as IoT sensors, Digital Twins, predictive maintenance, and automated control systems, hydrogen facilities can effectively monitor for leaks, respond in real time, and prevent accidents. Comprehensive safety strategies that combine proactive monitoring, emergency response, and data-driven risk management ensure a safer operational environment for hydrogen-related processes.