In many transmitter applications, shielded cables are required. Why is this? It has to do with the characteristics of shielded cables. We all know that signal interference during the use of instrumentation is highly undesirable. Using shielded cables for instrumentation can greatly reduce the likelihood of such occurrences.

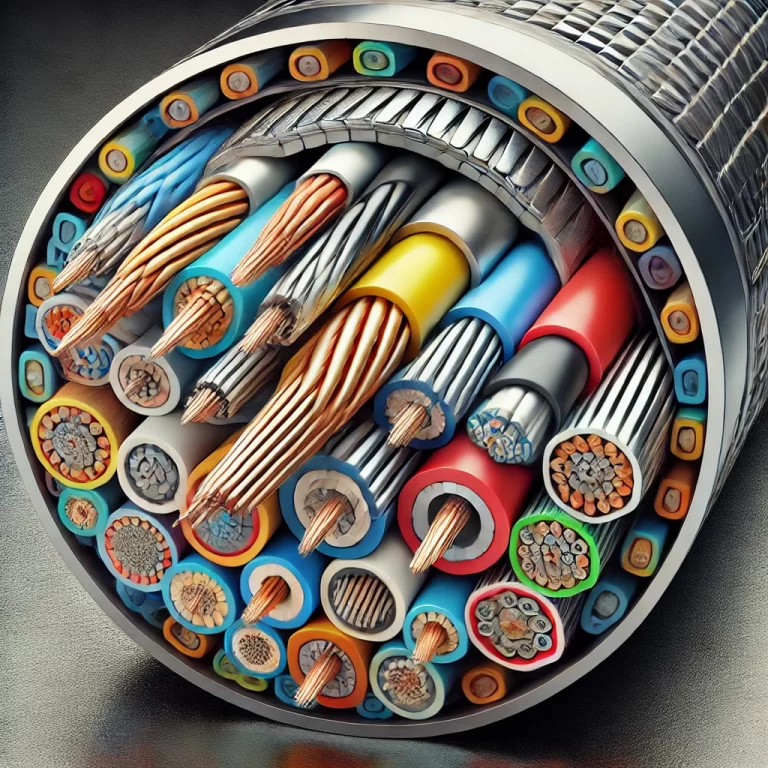

The shielding layer in shielded cables is typically a metal wire mesh designed to prevent electromagnetic interference from being superimposed on the normal signal. This helps to avoid measurement and control errors and even prevents disruption to the proper functioning of control systems and secondary instruments.

How should instrumentation and shielded cables be connected to effectively reduce the superposition of electromagnetic interference signals on normal signals? This requires that the shielded cables must be grounded. There are several specific methods for this:

Single-Point Grounding: The shielded layer is grounded at one end only, typically at the signal source or control room, to avoid ground loops and minimize interference.

Multi-Point Grounding: The shielded layer is grounded at multiple points along the cable, providing better protection in high-frequency applications, but care must be taken to avoid ground loops.

Floating Shielding: In certain cases, the shielding layer is not grounded but left floating, depending on the specific setup and nature of the interference.

Each method has its own application depending on the system requirements and interference levels. Proper grounding plays a key role in ensuring optimal performance of shielded cables in instrumentation systems.