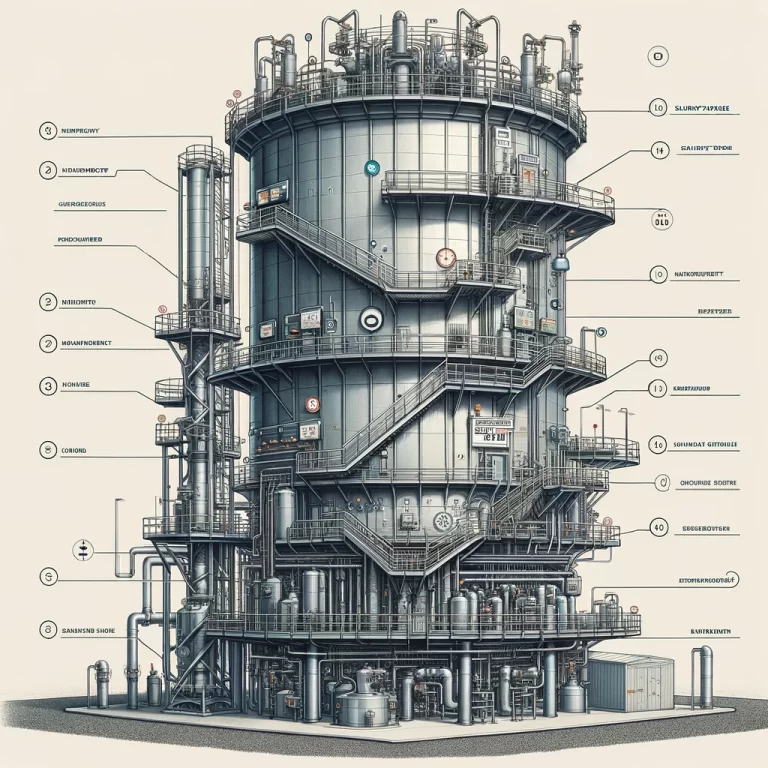

Level measurement technology is a crucial component of industrial automation control systems, especially in storage equipment like slurry storage towers. Accurate level monitoring is essential for ensuring the stability and safety of the production process.

Radar level meters, with their advantages of non-contact measurement, high precision, and strong anti-interference capabilities, have been widely applied in the field of slurry storage tower level measurement.

Key features and advantages of the radar level meter:

- Non-contact measurement: The radar level meter does not require direct contact with the liquid, preventing sensor contamination and wear, thereby extending the device’s service life.

- High-precision measurement: It provides accurate data even under complex working conditions, with measurement errors typically controlled within the millimeter range.

- Strong anti-interference capability: It is not easily affected by environmental factors such as temperature, pressure, steam, or dust, ensuring measurement stability.

- Easy installation and maintenance: The radar level meter is simple to install, has low maintenance costs, and supports remote monitoring through intelligent communication protocols.

The liquid in slurry storage towers often exhibits characteristics such as high temperature, high pressure, and corrosiveness, placing higher demands on the performance of the level meter.

Additionally, factors like foam, steam, and stirring equipment inside the tower can also affect measurement accuracy. Taking the slurry storage tower of a chemical plant as an example, the plant uses a high-frequency radar level meter for level monitoring.

Due to the corrosive and highly viscous nature of the medium inside the tower, traditional level measurement methods are difficult to adapt.

After comparative testing, the radar level meter demonstrated superior measurement performance, accurately reflecting changes in liquid level even in the presence of foam and steam.

Radar level meters have shown significant advantages in the measurement of slurry storage tower levels, meeting modern industrial demands for precision and reliability. As technology continues to advance, radar level meters are expected to become more intelligent and compact, leading to even wider application in the field of level measurement.

Additionally, with the challenges presented by increasingly complex and dynamic industrial environments, the continuous development of radar level meter technology will drive further innovation to meet the more stringent requirements of industrial measurement.