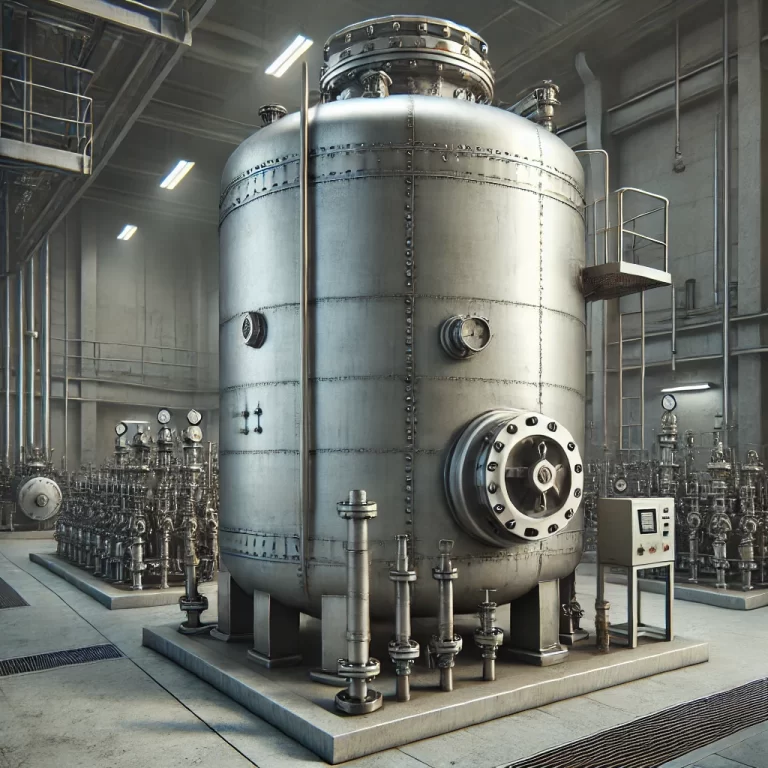

In working conditions such as dissolution tanks with high temperature, high pressure, and strong corrosion, traditional liquid level measurement methods often fail to meet the requirements.

With the advancement of technology, radar level meters have shown significant advantages in liquid level measurement of dissolution tanks due to their non-contact measurement, high adaptability, and high precision.

In the application scenario of the dissolution tank, radar level meters face a series of challenges. The dissolution tank is often accompanied by steam, foam and strong chemical corrosion, all of which may affect the measurement accuracy. The working principle of the radar level meter is based on microwave technology.

The transmitting antenna transmits microwave signals to the surface of the measured medium, receives the reflected signal, and calculates the height of the level according to the time difference or frequency change of the signal.

This measurement method does not require direct contact with the material, thereby reducing the risk of damage to the measuring equipment due to high temperature, corrosion and other factors, and ensuring the long-term stability and reliability of the measurement.

Therefore, when selecting a radar level meter, its operating frequency band, material, and signal processing capabilities need to be considered to adapt to complex working conditions.

High-frequency radar level meters are more suitable for measuring small targets and overcoming interference such as steam and foam due to their narrow beams; at the same time, radar level meters made of corrosion-resistant materials can better resist chemical erosion in dissolution tanks.

The choice of installation location is also critical. In order to avoid interference of the internal structure of the dissolution tank with the microwave signal, the radar level meter should be installed in a position that can avoid direct exposure to obstacles such as agitators and pipes.

At the same time, considering the turbulence and foam that may exist in the dissolution tank, a reasonable installation height and angle can help reduce measurement errors and improve the stability and reliability of data. Maintenance work should not be ignored either.

Although the radar level meter is a non-contact measurement, its antenna part may still be contaminated by the environment during long-term operation, such as the attachment of dust, crystals, etc. Regular cleaning and maintenance are the key to ensuring that the radar level meter continues to measure accurately.

At the same time, the use of modern communication technology to achieve remote monitoring and fault diagnosis of the radar level meter can greatly improve production efficiency and reduce maintenance costs.

The continuous advancement of technology has provided a new direction for the development of radar level meters. Higher frequency microwave signals, more advanced signal processing algorithms and intelligent data processing functions make the radar level meter more accurate and reliable in complex working conditions such as dissolution tanks.

In the future, with the integration of technologies such as the Internet of Things and big data, radar level meters will achieve a higher level of automation and intelligence, providing strong support for the control and optimization of complex industrial processes.