In the complex environment of the metal mining industry, radar level meters have become an indispensable tool for the industry due to their high accuracy and non-contact measurement.

This article aims to explore the application of radar level meters in the metal mining industry and the benefits they bring.

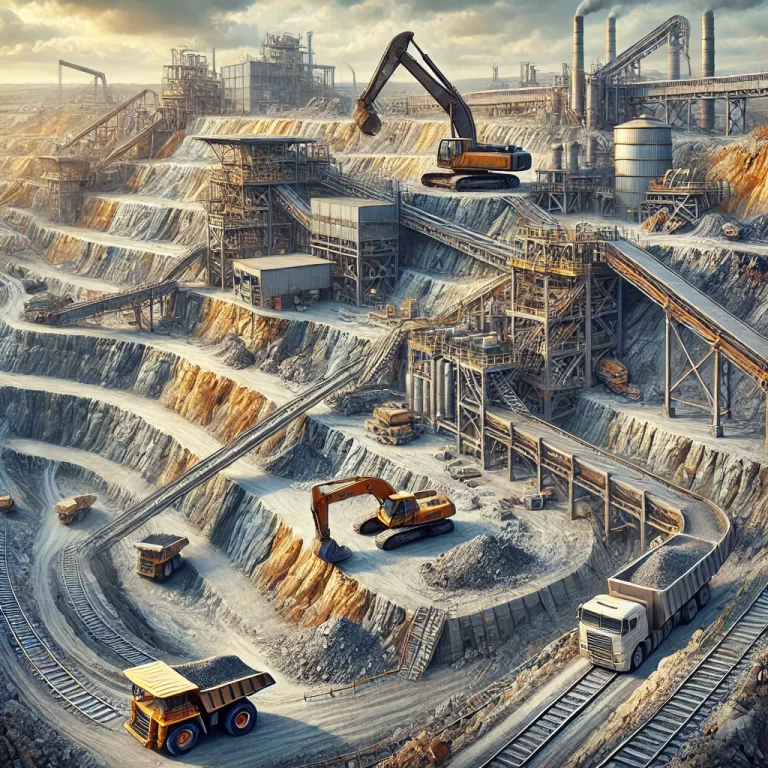

Metal mining involves the extraction of ore from deep within the earth, a process that is not only environmentally harsh but also places extremely high demands on measurement equipment.

Traditional level measurement methods such as floats, weights or ultrasound often fail or lack accuracy due to environmental factors. In contrast, radar level meters use high-frequency microwave signals for measurement, which can penetrate dust, steam and most weather conditions to achieve stable and reliable measurement results.

Radar level meters transmit microwave signals and receive their reflected waves. The device calculates the round-trip time of the signal and then determines the exact distance between the material surface and the radar. This process is not affected by temperature, pressure or material properties, making radar level meters particularly suitable for the changing working conditions of the metal mining industry.

Radar level meters are widely used in the metal mining process. For example, in the ore crushing process, accurate level monitoring helps optimize the efficiency of the crusher and avoid idling or overloading.

In the mineral processing stage, such as the flotation process, radar level meters can be used to monitor the liquid level of the slurry pool to ensure the stability of the process. In addition, for warehouses storing large amounts of bulk materials, radar level meters can monitor inventory levels in real time, assisting inventory management and logistics scheduling.

Radar level meters also play an important role in safety monitoring. In the management of tailings ponds, radar level meters can continuously monitor the stability of tailings dams and detect potential landslide risks in a timely manner, thereby protecting the safety of personnel and facilities.

At the same time, since radar level meters do not need to directly contact the measured medium, they reduce maintenance requirements and downtime, thereby improving overall operating efficiency.

Although the technical advantages of radar level meters are obvious, some key factors still need to be considered in practical applications.

For example, the choice of installation location must ensure that the microwave signal will not be interfered with and avoid dead angles. In addition, for materials with special dielectric constants, the radar level meter needs to be calibrated to ensure measurement accuracy.

The application of radar level meters in the metal mining industry demonstrates its excellent performance and flexibility. It not only improves the accuracy and reliability of measurement, but also provides a strong guarantee for safe production.