In grain storage management, accurate inventory measurement is an important part of ensuring smooth logistics and reducing losses.

As a common storage material, the physical properties of wheat have a significant impact on the selection of measurement tools.

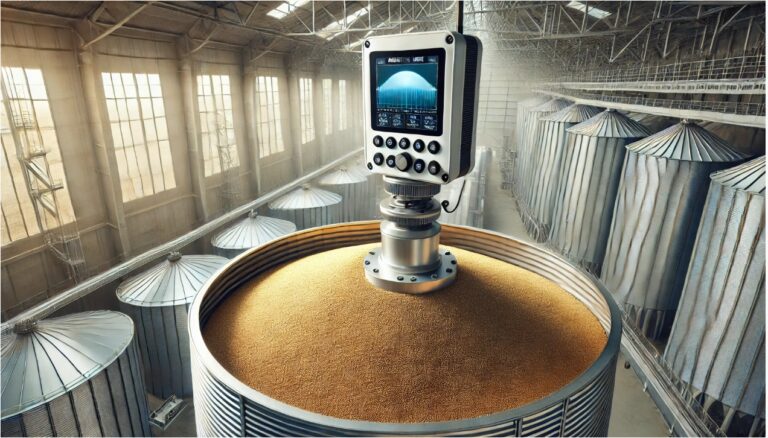

Radar level meters are widely used in monitoring wheat storage due to their non-contact measurement and high adaptability.

This article will explore the characteristics of wheat as a medium and analyze the performance of radar level meters in such applications.

As a granular dry material, wheat has the following characteristics:

1. Granularity: The size of wheat grains is relatively consistent, but the shape is irregular, which may cause gaps during storage and affect the measurement accuracy.

2. Hygroscopicity: Although wheat itself is relatively dry, it still has a certain degree of hygroscopicity. Changes in humidity will affect its dielectric constant, which in turn affects the reflection effect of radar waves.

3. Fluidity: The fluidity of wheat makes it easy to form a stacking angle during storage. The impact of changes in the angle of the material surface on the radar signal needs to be considered.

4. Density change: Affected by the degree of compaction and storage conditions, the bulk density of wheat will change, and the measurement equipment needs to be able to adapt to this change.

In view of the above characteristics, radar level meters have shown good adaptability and measurement accuracy:

1. Non-contact measurement: radar level meters measure distance by emitting microwave signals and receiving their reflected waves, avoiding direct contact with materials, reducing maintenance costs and measurement errors.

2. High adaptability: modern radar level meters have a variety of measurement modes, and can adjust the operating frequency and signal processing method according to the characteristics of the material to cope with materials with different dielectric constants such as wheat.

3. Accurate measurement: radar level meters can work stably under various temperature and pressure conditions, and are insensitive to irregular shapes on the surface of materials, ensuring the accuracy of measurement results.

4. Real-time monitoring: radar level meters can achieve continuous monitoring, provide real-time data for automatic control systems, and optimize warehouse management.

Radar level meter is an ideal choice for measuring granular materials such as wheat due to its high precision and non-contact characteristics.

It can not only overcome the challenges brought by the physical properties of wheat itself, but also adapt to the complex and changing storage environment to achieve efficient and accurate inventory management.