1. Working Principle

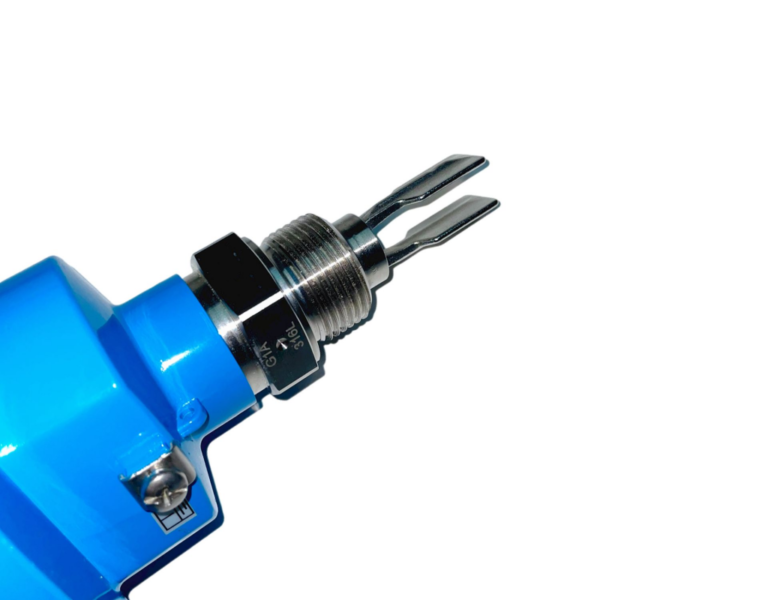

The tuning fork level switch is a liquid level measurement and control device designed based on the tuning fork principle.

Its working principle is to generate a resonant frequency by exciting the tuning fork. When the tuning fork comes into contact with the liquid, its vibration will be hindered, the resonant frequency will change or the vibration will stop completely, and then it can be judged whether the tuning fork is in contact with the liquid, thereby determining the height of the liquid level.

The tuning fork level switch is mainly composed of a tuning fork body, an excitation circuit, a detection circuit and an output circuit.

During operation, the excitation circuit sends an excitation signal to the tuning fork body to make it resonate.

When the tuning fork body is immersed in liquid, the damping effect of the liquid will change the vibration state of the tuning fork. The detection circuit determines the level of the liquid by detecting the vibration change of the tuning fork, and converts the result into a switch signal output through the output circuit.

The tuning fork level switch has the advantages of high sensitivity, fast response speed and good stability, and is widely used in various liquid level measurement and control occasions.

2. Common fault handling

1. No output signal

Fault cause: It may be a power failure, damage to the excitation circuit or a detection circuit failure.

Handling method: First check whether the power supply is normal, then check whether the excitation circuit and detection circuit are damaged. If damaged, replace the corresponding parts.

2. Malfunction

Cause of the fault: It may be due to improper installation position, impurities in the liquid or environmental interference.

Solution: Adjust the installation position to ensure good contact between the tuning fork and the liquid; clean up impurities in the liquid; take shielding measures to reduce environmental interference.

3. Unstable output signal

Cause of the fault: It may be due to large fluctuations in the liquid, obstructed vibration of the tuning fork, or circuit interference.

Solution: Adjust the installation position to reduce the impact of liquid fluctuations on the tuning fork; check whether there are obstacles around the tuning fork that hinder its vibration; check whether the circuit is interfered with and take corresponding shielding measures.

4. Shortened lifespan

Cause of failure: Fatigue of the tuning fork or aging of the material after long-term use.

Solution: Regularly replace the tuning fork or the entire level switch to ensure long-term stable operation.

5. Temperature influence

Cause of failure: The performance of the tuning fork may change in high or low temperature environments.

Solution: Select a tuning fork level switch that is suitable for different temperature environments; take insulation or cooling measures in high or low temperature environments; regularly check and maintain the tuning fork level switch to ensure its normal operation.

The above methods can effectively solve the common faults of tuning fork level switches and ensure their accuracy and reliability in level measurement and control. At the same time, regular maintenance and care of tuning fork level switches is also one of the important measures to prevent faults.