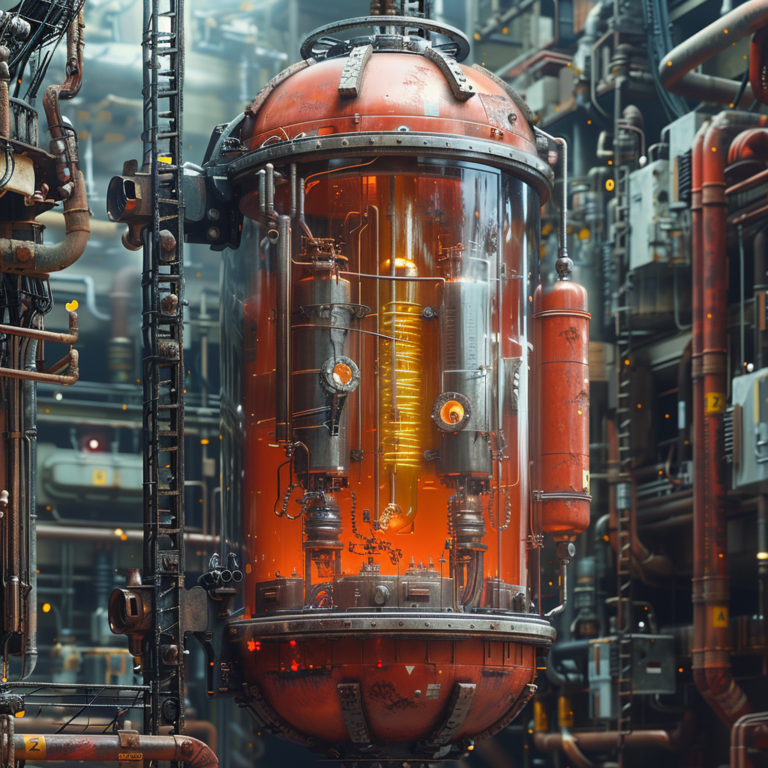

In the field of fine chemicals, creatine is an important raw material for nutritional supplements and sports enhancers. Its production process places extremely high demands on measurement technology. Among them, the creatine synthesis reactor is the core equipment of production.

Real-time monitoring of the internal materials is crucial to ensure the continuity and stability of production. This article will discuss the application of radar level meter in creatine synthesis reactor, and demonstrate its important role in industrial production through a practical case.

Creatine synthesis reactor is a closed container for creatine synthesis reaction, usually made of stainless steel or other corrosion-resistant materials.

During the production process, necessary raw materials such as glycine, methylglycine, etc. are added to the reactor, and these raw materials are chemically reacted to produce creatine by controlling conditions such as temperature, pressure and pH value.

Since the creatine synthesis process involves the change of multiphase substances, accurate measurement of the level in the reactor is particularly important.

Radar level meter is an instrument that uses the reflection principle of electromagnetic waves to measure the level of liquid, slurry or solid materials. It calculates the height of the level by emitting microwave signals and receiving the reflected signals.

In the creatine synthesis reactor, the radar level meter can provide non-contact continuous measurement, which is not affected by temperature, pressure, steam and corrosive media, and is very suitable for harsh industrial environments.

In order to accurately monitor the level in the reactor, engineers chose a high-frequency radar level meter for installation on the creatine production line of a chemical plant.

The radar level meter has an operating frequency of up to 26GHz and has excellent signal focusing ability.

It can stably measure the level even when there is foam, condensed water or strong stirring in the reactor.

During the installation process, the engineer first determined the best installation position of the radar level meter to ensure that its antenna part can cover the entire measurement range in the reactor.

Subsequently, the radar level meter was calibrated in zero point and range to adapt to the specific size of the reactor and the characteristics of the material. In actual operation, the radar level meter successfully achieved real-time monitoring of the level in the reactor.

By continuously tracking the level data, the operator can adjust the feed rate and reaction conditions of the raw materials in time to avoid the reaction out of control due to excessively high levels or the production efficiency affected by too low levels.

In addition, the data of the radar level meter is also integrated into the factory’s automation control system, further improving the intelligence level of the production process.

In summary, the application of radar level meter in creatine synthesis reactor not only improves the accuracy and reliability of measurement, but also provides strong support for production optimization and automatic control.

With the continuous advancement of technology, it is believed that radar level meter will play a more important role in future chemical production.