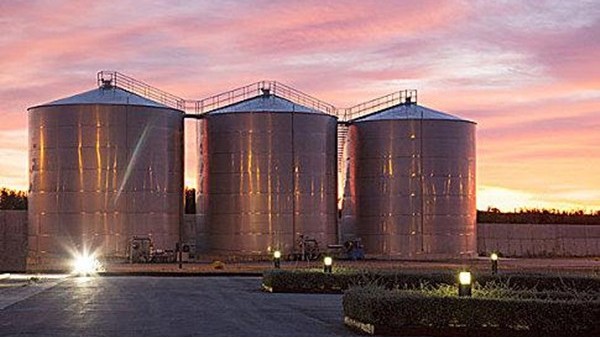

Storage towers are vessels used to store various liquid substances, and the measurement and control of liquid levels have always been a major difficulty in the operation of storage towers.

Traditional measurement methods such as manual measurement, pressure sensors, and float level meters often have problems such as low precision, poor stability, and susceptibility to environmental influences.

To solve these problems, the radar level meter, as an advanced liquid level measurement equipment, has gradually been widely used and recognized.

In the measurement of liquid level in the storage tower, there are the following difficulties: the influence of media properties: different liquid media have different dielectric constant, conductivity, density, and other physical properties, which affects the reflection and propagation of microwave signals, and need to be calibrated and adjusted for different media.

Temperature and pressure effects: temperature and pressure changes in the storage tower may lead to changes in the physical properties of the liquid, thus affecting the propagation and reflection of microwave signals, and the need for temperature and pressure compensation. Influence of agitator and piping: equipment such as agitators and inlet and outlet piping in the storage tower may interfere with the microwave signals and affect the measurement accuracy.

The impact of corrosion and cleanliness: the environment inside the storage tower is relatively harsh, there is corrosion dirt, and other problems, the radar level meter electronic components have an impact on the need to use corrosion-resistant, easy-to-clean materials.

Radar level meter is based on the principle of microwave transmission, by sending microwave signals to the inside of the storage tower and receiving the signals reflected back, the height of the liquid level is calculated. Its advantages are high measurement accuracy, good stability, and strong anti-interference ability, not easily affected by environmental factors.

At the same time, the radar level meter also has the advantages of non-contact measurement, can measure a wide range of media, and so on, applicable to various types of storage towers.

The oil storage tower of a chemical plant has frequent oil leakage and oil spillage accidents due to the low accuracy and poor stability of the traditional liquid level measurement method. In order to solve this problem, the plant adopted radar level meter for liquid level measurement.

According to the actual working conditions and use requirements of the storage tower, a radar level meter with high accuracy, high stability and corrosion resistance was selected. During the installation process, the radar level meter was accurately calibrated and adjusted to ensure that it could accurately measure the liquid level in various states.

After using the radar level meter, the level measurement accuracy of the oil storage tower of the chemical plant has been significantly improved, effectively avoiding the occurrence of oil leakage and oil spillage accidents, and improving the production safety and economic benefits.

As an advanced liquid level measurement equipment, radar level meter has a wide range of application prospects in the measurement of liquid level in the storage tower. By solving the shortcomings of traditional measurement methods, it can improve the accuracy and stability of liquid level measurement and provide a strong guarantee for the safety and stability of industrial production.