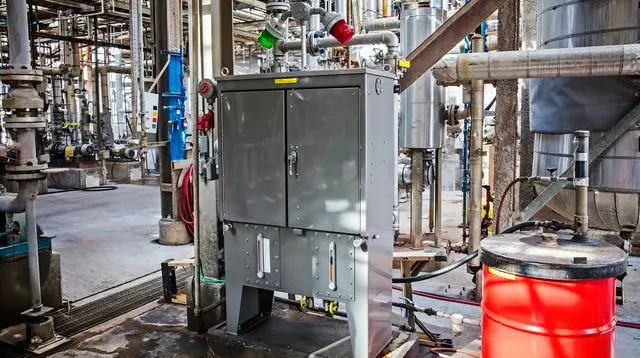

A radar level meter is a device that uses radar technology for level measurement and is widely used in industrial applications. In the hydraulic system, the hydraulic oil cabinet is a very important part, used to store hydraulic oil and keep the system running normally. A radar level meter is a commonly used tool for level measurement in hydraulic oil cabinets.

Hydraulic oil cabinet features:

1. large oil storage capacity: hydraulic oil cabinet usually has a large capacity, able to store a large amount of hydraulic oil. This is because in the hydraulic system, the hydraulic oil needs to provide stable hydraulic power, so there is a need to have enough storage space.

2. high-pressure tolerance: hydraulic system in the hydraulic oil cabinet needs to be able to withstand high pressure. In the hydraulic system, the hydraulic oil through the pump is pressurized and sent to the oil pipeline, and the hydraulic oil cabinet needs to be able to withstand this high pressure to ensure the normal operation of the system.

3. Provide a stable oil supply pressure: the hydraulic oil cabinet through the storage of a large amount of hydraulic oil, to be able to provide a stable oil supply pressure. In the hydraulic system, the stability of the oil supply pressure for the operation of the system is very important, the characteristics of the hydraulic oil cabinet ensure that the system has a stable oil supply pressure in the working process.

A radar level meter to measure the hydraulic oil cabinet level has the following advantages:

1. non-contact measurement: radar level meter is a non-contact measurement technology, that does not need to physically contact the level surface, so it will not interfere with the operation of the hydraulic oil cabinet. This is important for hydraulic systems as physical contact can lead to oil leakage or contamination.

2. Highly accurate measurements: Radar level gauges are able to provide highly accurate level measurements, often with millimeter-level accuracy.

This is very important for the control and monitoring of hydraulic systems to provide accurate level information so that timely adjustments and control can be made.

The following are two examples of actual radar level meter measurements of hydraulic oil cabinet levels:

1. There is an important hydraulic oil cabinet in a factory’s hydraulic system that is used to supply hydraulic power to a number of hydraulic presses. In order to ensure that the level of this hydraulic oil cabinet is always in the proper range, the factory uses radar level meters for measurement.

By monitoring level changes in real-time, the plant can replenish the hydraulic oil in a timely manner, keep the level stable, and ensure the normal operation of the hydraulic system.

2. A hydraulic crane at a construction site uses a radar level meter to measure the level of the hydraulic oil cabinet.

Hydraulic cranes need hydraulic power to successfully complete a variety of work tasks, so accurate control of the liquid level is very important to ensure the safety and efficiency of crane operation.

With the accurate level information provided by the radar level meter, the operator can monitor the level changes in real-time and replenish the hydraulic oil in time to ensure that the hydraulic crane is always in the best working condition.

To summarize, a radar level meter has many advantages in measuring hydraulic oil cabinet level, including non-contact measurement and high accuracy measurement. In practical applications, it can help engineers and operators monitor level changes in a timely manner to ensure that the level in the hydraulic oil cabinet is stable and the normal operation of the hydraulic system is ensured. Therefore, a radar level meter plays an important role in hydraulic oil cabinet level measurement.