Radar level meter is a liquid level measurement instrument commonly used in industrial production, which utilizes radar wave to measure the time difference between the object and the radar wave to determine the distance of the object, so as to accurately measure the liquid level.

In the process of industrial production, the measurement of liquid level is very important, involving the safety of production and production efficiency, and so on.

The emptying tank level measurement is an important application scenario of the radar level meter, this paper will analyze the characteristics of the emptying tank and two actual measurement cases

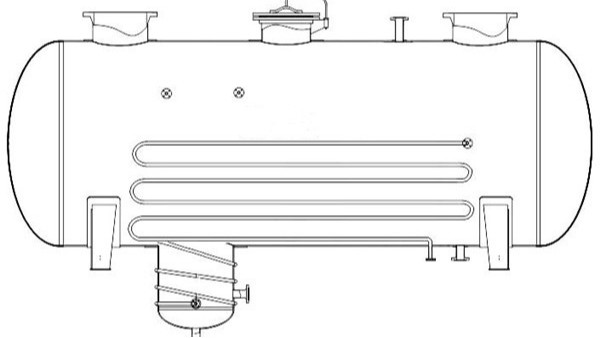

First of all, the venting tank is a kind of tank containing liquid, which needs to be discharged during the operation to maintain the normal operating pressure inside the tank. Unlike conventional liquid tanks, evacuated tanks have some characteristics in level measurement.

First of all, the level measurement of the emptying tank needs to take into account the flow of gas inside the tank. Because the venting tank needs to discharge gas, the tank will constantly gas through the liquid surface in and out, resulting in more complex changes in the liquid level.

Secondly, the level measurement of the emptying tank usually needs to take into account the influence of factors such as evaporation and sedimentation of the liquid.

Due to the flow of gas in the tank, the liquid is exposed to the gas for an increased period of time, evaporation is likely to occur; at the same time, some of the liquid may form slag, resulting in an increase in the level error.

Next, we will further illustrate the application of radar level meter in emptying tank level measurement through two actual measurement cases.

The first case is a chemical plant’s emptying tank level measurement. The emptying tanks of this chemical plant are filled with liquids with irritating odors, which need to be discharged continuously to maintain a good operating environment.

Due to the strong irritating liquid, the traditional level measurement method is easily affected, so the use of radar level meter to measure the emptying tank level has better stability and accuracy.

By installing the radar level meter on the emptying tank and setting the level alarm value reasonably, it can accurately monitor the change of the liquid level in the tank and alert the operator to empty the tank in time. The second case is a petroleum storage tank emptying tank level measurement.

The petroleum storage tank is used to store crude oil, and in the production process, it is also necessary to regularly empty the tank to maintain the appropriate pressure.

Due to the special nature of crude oil, there are a lot of sludge and volatile components in the tank. In this case, the traditional liquid level measurement method is susceptible to the interference of slag, and the accuracy is low.

While radar level meter has strong anti-interference ability and accurate measurement results, so it is more suitable for the level measurement of petroleum storage tanks.

Through reasonable installation and setting, it can accurately measure the level of emptying tanks of petroleum storage tanks to ensure the safety and efficiency of production.

Through reasonable installation and setting, the radar level meter can accurately measure the liquid level of the emptying tank.

In practical application, we need to choose the right radar level meter model according to different situations and make reasonable settings for the characteristics of the emptying tank, in order to improve the accuracy and stability of liquid level measurement.

With the continuous development of science and technology, radar level meters will play an important role in more liquid level measurement scenarios, bringing greater convenience and benefits for production.