Radar level meter is a commonly used measurement tool, which is widely used in industrial production. However, when using a radar level meter for measurement, the problem of foam is sometimes encountered. The presence of foam may interfere with the measurement results, so a solution is needed.

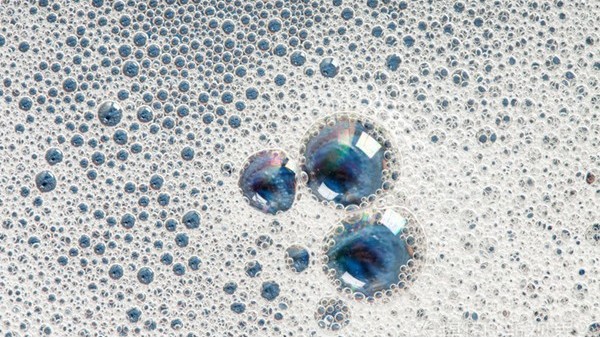

First of all, let us first understand what is the foam problem. A foam is a small bubble formed by the gas in the liquid, when the microwave signal emitted by the radar level meter encounters the foam, it will be reflected and refracted, resulting in measurement errors.

Foam problem mainly occurs in the following working conditions:

1. liquid agitation: when the liquid is agitated, a large number of bubbles will be generated, and these bubbles will interfere with the measurement of the radar level meter.

2. liquid injection: in the process of liquid injection, due to the contact between the liquid and the air, a large number of bubbles will be formed, thus interfering with the measurement of the radar level meter.

3. liquid foam: some liquids have a high degree of foam properties in themselves, such as detergents, cleaners, etc., which can lead to the measurement error of the radar level meter. For example, detergents, cleaners, etc., these bubbles will interfere with the measurement of the radar level meter.

For the above working conditions, we can take the following solutions to deal with the foam problem:

1. choose the right radar level meter: when purchasing radar level meters, you can consider choosing models with anti-foam functions. These models of radar level meters usually have special signal processing algorithms, which can effectively inhibit the interference of foam.

2. Adjust the parameters of the radar level meter: For the radar level meter that has been installed, you can reduce the interference of foam by adjusting its parameters. For example, the transmit power and receive sensitivity of the radar level meter can be adjusted to optimize the measurement effect.

3. Use of foam reducer: For liquids that are prone to foam, adding a certain amount of foam reducer can be considered. Foam reducer can destroy the surface tension of the foam, so that the foam quickly dissipates, thus reducing the interference of foam on the radar level meter.

4. change the liquid process: in some cases, you can change the liquid process to reduce the generation of foam. For example, the mixing speed, spray angle, etc. can be adjusted to minimize foam formation.

5. Regular cleaning of the radar level meter: Regular cleaning of the antenna and sensors of the radar level meter can be effective in preventing foam buildup.

Mild cleaning agents can be used for cleaning, avoid using cleaning agents containing solvents or strong acidity or alkalinity, so as not to cause damage to the radar level meter.

It should be noted that when solving foam problems, we should take appropriate measures according to the specific situation. At the same time, in order to ensure the safety and reliability of the operation, it is recommended to communicate and confirm with relevant professionals before implementing the solution.

In conclusion, it is common for radar level meters to encounter foam problems during the measurement process. Choosing the right type of level meter, adjusting parameters, using a foam reducer and other methods can reduce the interference to complete the normal measurement.