In the petrochemical industry, radar level meters and guide wave radar level meters are both relatively commonly used level meters. Some users often ask which one is the most suitable.

In fact, the choice of radar level meter or guide wave radar level meter needs to be determined according to the working conditions.

Today we analyze what are the similarities and differences between these two types of level meters in the petrochemical industry.

The radar level meter is a very advanced measuring instrument suitable for applications in the oil industry, emitting a series of radar pulses and analyzing the reflected echoes to calculate distances.

It consists of a structure with a housing for the electronics, which is mounted on a flanged antenna element.

The electronics generate the radar signal and send it directly to the antenna. The radar signal is emitted on the axis of the antenna and propagates along that axis at a finite cone beam angle, the radar signal gradually attenuates and the intensity is inversely proportional to the square of the distance.

After the radar signal is emitted, it encounters the surface of the liquid being measured and is then reflected back.

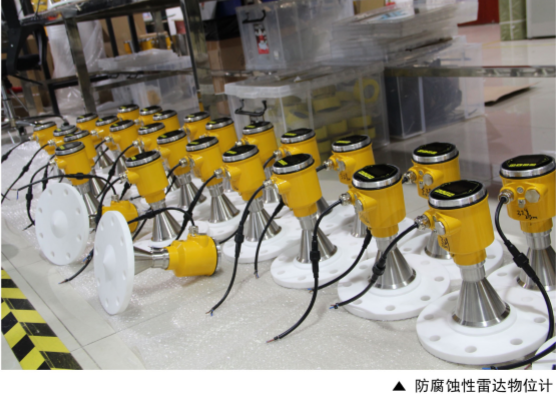

The reflected echo can be picked up by the antenna in the electronic unit receiver. The echoes are stored in an envelope of changing states in the vessel. By analyzing this envelope, the distance between the radar antenna and the material surface can be calculated. The main feature of radar level meters in the petrochemical industry is their relatively corrosion-resistant structure, mostly aluminum or stainless steel housings, which have a relatively long service life.

The measurement accuracy is relatively high, generating relatively small errors, and can be used continuously without manual measurement. And the signals sent can be transmitted over long distances, which is conducive to observing changes in the liquid level.

The measurement principle of a guided wave radar level meter is that when a pulse-transmitting device emits an electromagnetic wave signal, the signal gradually decays when it reaches the surface of the medium and returns. Currently, the strength of the signal is proportional to the dielectric constant of the medium.

The greater the value of the dielectric constant, the stronger the strength of the reflected signal and, conversely, the weaker the reflected signal. The lowest dielectric constant that can be measured by a guided wave radar level meter is 1.4 for medium-level measurement at medium level.

Stronger reflected pulses are generated by external highly conductive media, such as water. However, low-conductivity media can produce relatively weak reflective pulses.

The low conductivity medium allows some electromagnetic waves to continue to operate along the probe down through the surface of the liquid until it is completely dissipated or reflected by the higher conductive medium.

Depending on this function, a guided wave radar horizontal gauge can be used to measure both liquid interfaces, such as those of oil or water, where the dielectric constant of the liquid under the interface should be much larger.

In general radar level meters, and guided wave radar level meters have their advantages and disadvantages in petroleum industry applications, they can generally be applied, using ordinary radar as the non-contact measurement, using guided wave radar is contact measurement, which means that guided wave radar needs to consider the corrosiveness and adhesion of the medium, long guided wave radar installation, and maintenance becomes more difficult.

However, ordinary radars can be used interchangeably, but guided wave radars are usually not interchangeable because the length of the probe is determined by the original working conditions. When measuring solid materials, guided wave radar also needs to take into account the forces on the probe.

Due to the forces, the distance measured by guided wave radar is usually not too long, but ordinary radar can be used on tanks of thirty or forty meters, and sometimes even up to sixty meters. However, under some special conditions, the advantages of guided wave radar are obvious, such as agitation in the tank, or large fluctuations in the medium, etc.

It is more stable to use a guided wave radar fixed at the bottom for measurement. There is also the measurement of the liquid level in small tanks, due to the small installation measurement space usually ordinary radar is not applicable.